at wits end HELLPPPP please

- Thread starter AcidRayn

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ok, this explains some things. i have 2 manuals, both downloaded from here,

take a look,

this kinda crap can make a man beat his woman!

k, guess im goin to buy a coil. im bringing my tester with me and reading it right there.

im off to the garage to clean some grounds. might even throw in the other wiring harness i have just to rule that out.

thanks guys, and some rep's for all whose helping me out

My service manual says the same thing but it is worded different and looks to be different years different numbers, I'm gonna have to check that when i get home.

maybe a bad tester?

Not a chance. I'm a high voltage splicer and also specialize in instrumentation trouble shooting. My meters and equipment are sent out for certified calibration every 3 months. You don't want to be off even .00001 of a percent when your testing and certifying gauges on a nuclear power plant console.

Meter I'm using is over 10,000$ and was just calibrated 2 weeks ago.

I think that is the one thing I can rule out.

Me and my kid are having alot of garage time together. This project is teaching him alot. He's already asking if we can start buying basket cases to rebuild and sell so he can keep working on them.

Enough of that, I got to get out there. He just got the carb off

Me and my kid are having alot of garage time together. This project is teaching him alot. He's already asking if we can start buying basket cases to rebuild and sell so he can keep working on them.

awsome, kinda like the "teach a man to fish" quote

teach a kid to ride, he'll ride it till it breaks, teach a kid to fix and maintain it, he'll always have a ride

Ok guys, I found a few things out and there are big changes so maybe save this info, I know i've used the wrong info already!

For years 1987-2002

Spark plug minimum gap of

Spark plug cap resistance 4~6k Ω

Ignition coil Primary resistance 1.44~1.76 Ω

Ignition coil secondary resistance 5.28~7.92K Ω

Source coil resistance 192~288 Ω

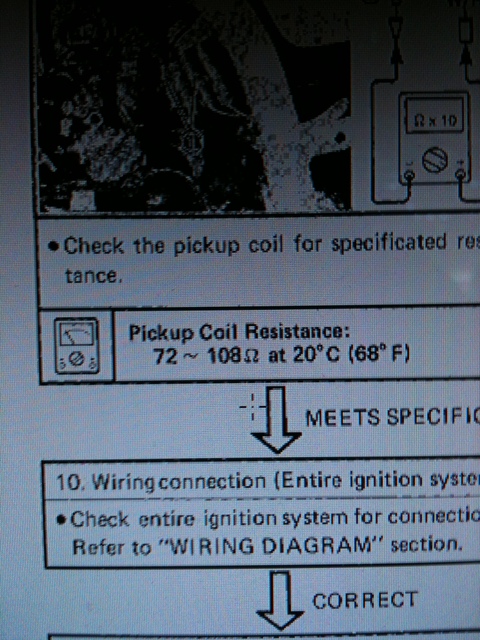

Pickup coil resistance 72~108 Ω

2003-2007 (yes they made them just not in the USA) then you go by this (again 68*F):

Spark plug minimum gap of 0.7mm~0.8mm or 0.028~0.032 In

Spark plug cap resistance 10k Ω

Ignition coil Primary resistance 0.18~0.28 Ω

Ignition coil secondary resistance 6.32~9.48k Ω

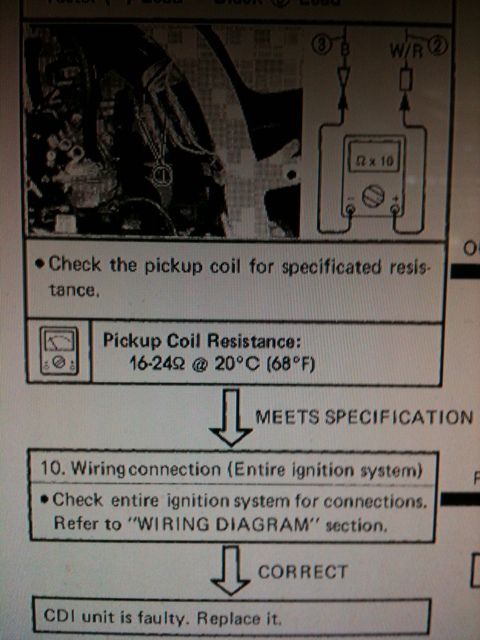

Pickup coil resistance 16~24 Ω

For years 1987-2002

Spark plug minimum gap of

Spark plug cap resistance 4~6k Ω

Ignition coil Primary resistance 1.44~1.76 Ω

Ignition coil secondary resistance 5.28~7.92K Ω

Source coil resistance 192~288 Ω

Pickup coil resistance 72~108 Ω

2003-2007 (yes they made them just not in the USA) then you go by this (again 68*F):

Spark plug minimum gap of 0.7mm~0.8mm or 0.028~0.032 In

Spark plug cap resistance 10k Ω

Ignition coil Primary resistance 0.18~0.28 Ω

Ignition coil secondary resistance 6.32~9.48k Ω

Pickup coil resistance 16~24 Ω

Last edited:

Ok guys, I found a few things out and there are big changes so maybe save this info, I know i've used the wrong info already!

For years 1987-2002

Spark plug minimum gap of 6.0mm or (0.24 inches)

Spark plug cap resistance 4~6k Ω

Ignition coil Primary resistance 1.44~1.76 Ω

Ignition coil secondary resistance 5.28~7.92K Ω

Source coil resistance 192~288 Ω

Pickup coil resistance 72~108 Ω

2003-2007 (yes they made them just not in the USA) then you go by this (again 68*F):

Spark plug minimum gap of 7.0mm or (0.28 inches)

Spark plug cap resistance 10k Ω

Ignition coil Primary resistance 0.18~0.28 Ω

Ignition coil secondary resistance 6.32~9.48k Ω

Source coil resistance There isn't one

Pickup coil resistance 16~24 Ω

wow, nice find. you look all this up or found it somewhere?

this explains a couple things, but not others.

again, im working with 2 blasters, a 98 and an 02. im using the ignition/stator set up outa the 02, simply cuz it was cleaner, and the kid i got it from said it was replaced with a new yamaha set last year, so that explains the numbers on the pickup coil, but on the ignition coil, im pretty sure they are both originals, i think i can pretty much assume the 98 is original, as that bike has sat since 2000 in pieces, so the guy said that i got it from.

now, for tonights updates, i (brian) pulled the carb, we broke it down again, this time paying alot of attention to the enrichener circuit, and it was clear, i even took the metering jet out of the bowl and it was crystal clear.

i put in a new pilot, 35, and a new main, 260. the 32.5 pilot was clean and clear, this move was a just because move, i can always go back to the 32.5.

now, i pulled the reeds, they are v force 3's. i am not impressed with the design of the reed cage. with a straight edge, the plastic seat is kina concave, its slight and i was too lazy to get the feeler gauges outa the tool box to get a measurement, but the reeds are not sitting true flat.

this v force was on the bike when i got it and i dont have another set of reeds at the moment, so i took them all apart, checked very close under the loop for cracks. the corners of the carbon fiber are worn. im not familiar with carbon fiber reeds so i dont know for sure, but they dont look kosher. i cleaned them up good and flipped them, now they are sitting decent, i will replace soon.

re did leak down test, 7psi for an hour.

now, the big question, in the intake, that indent at the very rear most part of the intake, had oil puddled up in it. quite a bit. it was 2 stroke oil.

any suggestions on this one?

its back together and i cant run it till the morn, pisses off the wife when i fire up toys this late.

ill report in tomorow

wow, nice find. you look all this up or found it somewhere?

this explains a couple things, but not others.

I looked through my service manual and all the info with the supplimental info for the 2003-up was there too, i though that all the stators were the same reguardless of years, i was wrong.

As far as the reeds, once I flipped them they are sitting flat. The cage is actually pitted and concave a bit. With the work I do I'm use to things be just about perfect. Very close tolerances. I'll fire it up today and see

Thanks for the time yOu took for that info slickerthanthou. It's very useful. I printed it and put it in my file of notes.

As far as the oil puddles, I wasn't sure. When I had the banshee I don't remember there being a spot like that, and that is the most 2 stroke exp I have memory of. Lol

Thanks for the time yOu took for that info slickerthanthou. It's very useful. I printed it and put it in my file of notes.

As far as the oil puddles, I wasn't sure. When I had the banshee I don't remember there being a spot like that, and that is the most 2 stroke exp I have memory of. Lol

How long did it run to get the puddle?

It's normal for oil to puddle in the crankcase, under the reeds, and on the transitions into the transfers... the only reason to be concerned over that would be if the engine hasn't been run, maybe you're getting too much fuel.

Vforce cages are known to be a little... warped sometimes. People have real problems with them sealing up against the cylinder because of their warp.

It's normal for oil to puddle in the crankcase, under the reeds, and on the transitions into the transfers... the only reason to be concerned over that would be if the engine hasn't been run, maybe you're getting too much fuel.

Vforce cages are known to be a little... warped sometimes. People have real problems with them sealing up against the cylinder because of their warp.

Well Brian, just got done reading through all of this.

Few things, for one after all of the electrical info provided ,seems like you are good there, all tolerances look good, etc. Not much more (gremlins) to iron out there.

my questions go like this. You said earlier that you had 2 carbs, same thing with both??? Then you said Yami tech spoke of choke possibilities, etc. Did you have the SAME issues with both carbs?

You seem OK now with the Reed cage, and yes the V3's tend to run a little warped and not sit tight, hence me not using them anymore. But, as Brando said once you are sitting flat you should be good, a little permex will not hurt either to assure a good flat sealed seat.

BUT, you are holding 7psi all day so does not seem like an air leak, due to reed cage, etc, etc.

Have you swapped out and successfully tested the CDI from both units you have? I have had similar issues to this being CDI related.

Also did you try running it without the filter altogether, no lid, no filter, etc?

AND, with TORS are you sure it is gone/removed?

Still have the TORS Brain on top of the carb? Properly run through the entire system assuring a full delete?

TORS DELETE

Just another thing to consider, as TORS can really F a man's day up.

Everything else seems to be covered, you are certainly on the right track.

keep us posted after some further testing with that carb job, etc.

Few things, for one after all of the electrical info provided ,seems like you are good there, all tolerances look good, etc. Not much more (gremlins) to iron out there.

my questions go like this. You said earlier that you had 2 carbs, same thing with both??? Then you said Yami tech spoke of choke possibilities, etc. Did you have the SAME issues with both carbs?

You seem OK now with the Reed cage, and yes the V3's tend to run a little warped and not sit tight, hence me not using them anymore. But, as Brando said once you are sitting flat you should be good, a little permex will not hurt either to assure a good flat sealed seat.

BUT, you are holding 7psi all day so does not seem like an air leak, due to reed cage, etc, etc.

Have you swapped out and successfully tested the CDI from both units you have? I have had similar issues to this being CDI related.

Also did you try running it without the filter altogether, no lid, no filter, etc?

AND, with TORS are you sure it is gone/removed?

Still have the TORS Brain on top of the carb? Properly run through the entire system assuring a full delete?

TORS DELETE

Just another thing to consider, as TORS can really F a man's day up.

Everything else seems to be covered, you are certainly on the right track.

keep us posted after some further testing with that carb job, etc.

How long did it run to get the puddle?

i'd say its run maybe 10 min, 10 min, 15 min, had it fired up 3 times

It's normal for oil to puddle in the crankcase, under the reeds, and on the transitions into the transfers... the only reason to be concerned over that would be if the engine hasn't been run, maybe you're getting too much fuel.

Vforce cages are known to be a little... warped sometimes. People have real problems with them sealing up against the cylinder because of their warp.

just to clarify, i had a problem with the leakdown test, and yes i had to use some permatex copper to seal up the reed block, very light film, im talking about where the pedals contact the cage. the surface the reeds lay on is actually pitted at the corners, and the carbon fiber was beat up there, hard to describe and the pics dont really show it, i sanded them lightly, carbon fiber does tool very well, and they are sitting better. im gonna get a fmf set up today, i dont like this reed block set up at all, plastic dont belong in there in my opinion, and reading all the peeps having trouble with them, not worth it

Well Brian, just got done reading through all of this.

Few things, for one after all of the electrical info provided ,seems like you are good there, all tolerances look good, etc. Not much more (gremlins) to iron out there.

my questions go like this. You said earlier that you had 2 carbs, same thing with both??? Then you said Yami tech spoke of choke possibilities, etc. Did you have the SAME issues with both carbs?

yes, same issue with both carbs, checked metering valve on both, carb #1 it was definitly clogged, get get the valve out, carb # 2 was spotless, good flow thru the tube, this carb cleaned up very nice, had no scale or varnish, was just dirty on the outside, so its the better choice

You seem OK now with the Reed cage, and yes the V3's tend to run a little warped and not sit tight, hence me not using them anymore. But, as Brando said once you are sitting flat you should be good, a little permex will not hurt either to assure a good flat sealed seat.

see above, they are junk, plastic dont belong in there!

BUT, you are holding 7psi all day so does not seem like an air leak, due to reed cage, etc, etc.

Have you swapped out and successfully tested the CDI from both units you have? I have had similar issues to this being CDI related.

not yet, after i run it this morning, if prob persists, that is next course, along with complete wiring harnesse swap out or i'll just rewire it and keep it basic, to be continued.....

Also did you try running it without the filter altogether, no lid, no filter, etc?

filter has not been put on at all, all testing has been done with nothing attached to the carb

AND, with TORS are you sure it is gone/removed?

Still have the TORS Brain on top of the carb? Properly run through the entire system assuring a full delete?

TORS DELETE

the tors box is removed from under the hood, the brain is on top of the carb disconected, i will print and use that info today after running it if prob persists, and just to clairify, this backfiring was happening with the tors sys connected and disconected

Just another thing to consider, as TORS can really F a man's day up.

Everything else seems to be covered, you are certainly on the right track.

keep us posted after some further testing with that carb job, etc.

the tors will be gone 100%, they have no use in this mans army and i hated the system since my banshee days, i ordered a new cable and carb top, just has not got here yet

just wanna through out a big thanks for all adding info to this case, i will win!!! just a matter of how long the war will be. lol

o yea, a public service announcement, be VERY VERY careful when working on your bike in the garage, that is attached to the house, and is right next to the room with the furnace, that when its late you dont SET DOWN THE GAS TANK AND ACCIDENTLY REST IT ON THE PETCOCK AND HAVE IT DRIP GAS INTO THE GARAGE ALL NIGHT!!!!!!!!! we woke up and the entire downstairs was full of gas fumes!!! THANK GOD I HAVE OIL HEAT!!! y you may ask is that a blessing?, oil heats flames are in an enclosed fire box, gas heats flames are open to the public. furnace did not come on last night, but had it, and had we have gas heat, well, i'm sure i'd be typing this from the burn ward and not worrying about this blaster anymore!! be carful

10 minutes is more than enough to accumulate oil under the reeds. That's fine!

I understand where you're talking about. The problem is injection molding shrinkage, it's all over. The mating surface is usually the one people talk about because it's obvious when it doesn't line up with the cylinder mating surface. In reality the plastic is warped all over. Most people simply don't notice...

For your purposes it's ok that the reeds are a little tattered on the corner but replacements are a good idea.

I would go with an electrical change out on this one. You've covered all of the other bases. It should at least starting and running (maybe not really well but starting and running at least) with all of the stuff you've checked out.

I understand where you're talking about. The problem is injection molding shrinkage, it's all over. The mating surface is usually the one people talk about because it's obvious when it doesn't line up with the cylinder mating surface. In reality the plastic is warped all over. Most people simply don't notice...

For your purposes it's ok that the reeds are a little tattered on the corner but replacements are a good idea.

I would go with an electrical change out on this one. You've covered all of the other bases. It should at least starting and running (maybe not really well but starting and running at least) with all of the stuff you've checked out.

10 minutes is more than enough to accumulate oil under the reeds. That's fine!

I understand where you're talking about. The problem is injection molding shrinkage, it's all over. The mating surface is usually the one people talk about because it's obvious when it doesn't line up with the cylinder mating surface. In reality the plastic is warped all over. Most people simply don't notice...

For your purposes it's ok that the reeds are a little tattered on the corner but replacements are a good idea.

I would go with an electrical change out on this one. You've covered all of the other bases. It should at least starting and running (maybe not really well but starting and running at least) with all of the stuff you've checked out.

yea, its pretty much where im at. if so much as a pop, wiring harness first (the one on there has too many repairs for my like) then cdi, then 12 ga 002 buckshot. lmao. i have to take boy child 2 to the oral surgeon this morning, and if the little 8 yr ol bastard does not throughly wipe me out, i will work on this when we get back. and its not helping that its pouring hear all day so i cant put the harley outside, so makes the garage very cramped, and if it runs test rides will surely suck. o well, its for the betterment of mankind. lol will post up later.

Ok guys, I found a few things out and there are big changes so maybe save this info, I know i've used the wrong info already!

For years 1987-2002

Spark plug minimum gap of 6.0mm or (0.24 inches)

Spark plug cap resistance 4~6k Ω

Ignition coil Primary resistance 1.44~1.76 Ω

Ignition coil secondary resistance 5.28~7.92K Ω

Source coil resistance 192~288 Ω

Pickup coil resistance 72~108 Ω

2003-2007 (yes they made them just not in the USA) then you go by this (again 68*F):

Spark plug minimum gap of 7.0mm or (0.28 inches)

Spark plug cap resistance 10k Ω

Ignition coil Primary resistance 0.18~0.28 Ω

Ignition coil secondary resistance 6.32~9.48k Ω

Source coil resistance There isn't one

Pickup coil resistance 16~24 Ω

Sorry to jack your thread Brian, but a couple small corrections...

The 6 an 7 mm spark plug minimum gaps that Slick mentioned are actually the minimum settings on a spark gap tester that Yamaha talks about in the manual. Plug gap is .7 to .8mm (.028-.032 inches) on all machines. Also, there is a source coil resistance for the newer quads, they just call it "charging/rotor rotation direction detection coil resistance". It is the same resistance as the older ones.

BTW, anyone who wants a 01-02 and/or 03+ Manual Supplement, just PM me your email address!

Sorry to jack your thread Brian, but a couple small corrections...

The 6 an 7 mm spark plug minimum gaps that Slick mentioned are actually the minimum settings on a spark gap tester that Yamaha talks about in the manual. Plug gap is .7 to .8mm (.028-.032 inches) on all machines. Also, there is a source coil resistance for the newer quads, they just call it "charging/rotor rotation direction detection coil resistance". It is the same resistance as the older ones.

BTW, anyone who wants a 01-02 and/or 03+ Manual Supplement, just PM me your email address!

HAAAAAAA nice catch! You are correct sir! Man that's what I get for hurrying! Thanks bro! I fixed it now.

Don't forget to disconnect the parking brake switch when disconnecting the TORS. I spent hours trying to figure out my son's 03 Blaster. Runs great now!

okay, heres an update

IT FRIGGING RUNS!!!!!!!!!!!

after tearing the carb down again, swaping jets, cleaning the pet weiner, re dressing the reeds,

testing and re installing the coil, dressing up the ground connections, all 2 of them.

it was still backfiring. tors is completely disconected, same problem.

i pulled the wiring harness and cdi box off the other frame.

also started thinking about fuel more and the premix.

im a blendzall guy, been running castor since that was all there was to use, long before syntheics

i was running at 20:1 for break in, so i dumped that and went to 32:1 and changed out the cdi

the jets are a 260 main and a 40 pilot at 1 1/4 turns

it is now firing up on the first kick. let it run for a bit with a fan on it, shut it down, cool off, repeat

tommorow im going to put the complete wiring harness on it and plastics, air filter and get it out to start the jetting

process.

thanks to all for your help, its truly appreciated.

IT FRIGGING RUNS!!!!!!!!!!!

after tearing the carb down again, swaping jets, cleaning the pet weiner, re dressing the reeds,

testing and re installing the coil, dressing up the ground connections, all 2 of them.

it was still backfiring. tors is completely disconected, same problem.

i pulled the wiring harness and cdi box off the other frame.

also started thinking about fuel more and the premix.

im a blendzall guy, been running castor since that was all there was to use, long before syntheics

i was running at 20:1 for break in, so i dumped that and went to 32:1 and changed out the cdi

the jets are a 260 main and a 40 pilot at 1 1/4 turns

it is now firing up on the first kick. let it run for a bit with a fan on it, shut it down, cool off, repeat

tommorow im going to put the complete wiring harness on it and plastics, air filter and get it out to start the jetting

process.

thanks to all for your help, its truly appreciated.

Last edited:

running too much oil will actuall lean it out. you should breakin at what you are going to run always. should have posted that earlier.

Similar threads

- Replies

- 3

- Views

- 353