high rev?

- Thread starter 91yamahablaster

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

previouse owner did some sort of oil block off im not sure where the oil thing hooks up to the carb but its not there the only line i have on it is gas line and guess i have to leak test again. is it possible i could get these sypmtoms from a improperly jetted carb or a air screw not right?

just rememberd somthing somtimes when i rev it there will be a soild knock in the engine i thought the spark plug was hitting piston but no and its only once in a while

how do i go about capin it off and ill call a friend and get that compression tester. could a air leak cause a knock?

ok so that seems to of fixed it  but now i got a bad bog problem at about mid throttle i bog all the way through then once get to the top it rips and at the low end it has surprising torque but boggy as hell in the mid range

but now i got a bad bog problem at about mid throttle i bog all the way through then once get to the top it rips and at the low end it has surprising torque but boggy as hell in the mid range

still sounds lean. if i knew more about these bikes im going to be in the elkhart area friday i eould stop by and try to help you but i dont kbow nearly enough about them.

well hell if i get the dam thing running right by then your welcome to come ride it and should i adjust air screw or try plug chopping? just not sure how to get rid of this lean issue

well hell if i get the dam thing running right by then your welcome to come ride it and should i adjust air screw or try plug chopping? just not sure how to get rid of this lean issue

if this is the stock one with a uni id bump the main jet one and then plug chop and see where your at... im no good at jetting, but if the motor is airtight then it should be close. My dad is moving to bremen so thats why id be in the area.

So you have capped the air leak on the carby.

I am presuming that you have cleaned the carb, set the float level, and it has passed a leak down test.

The next thing to do is to adjust your idle as it will affect jetting above it.

Idle adjusting.

Start with air screw 1.5 turns out.

Set idle screw so that it has some sort of idle.

Warm up motor and then set idle screw for a fast idle.

Adjust air screw either way to get the fastest idle.

Adjust air screw a little at a time leaving 10 secs to allow the motor to respond.

Re adjust idle screw for desired idle .

I am presuming that you have cleaned the carb, set the float level, and it has passed a leak down test.

The next thing to do is to adjust your idle as it will affect jetting above it.

Idle adjusting.

Start with air screw 1.5 turns out.

Set idle screw so that it has some sort of idle.

Warm up motor and then set idle screw for a fast idle.

Adjust air screw either way to get the fastest idle.

Adjust air screw a little at a time leaving 10 secs to allow the motor to respond.

Re adjust idle screw for desired idle .

ok ill go try to get that air screw set right now and one other thing im noticing is that when i rev it it seems to hang to long till it returns to idle?? i cant figure it out

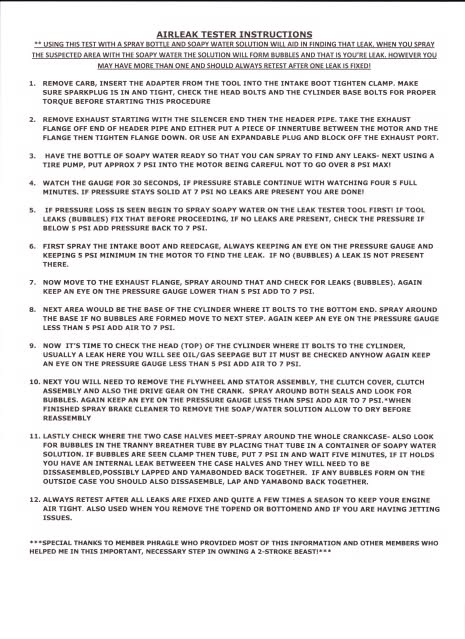

What were the results of the leak down test, did it hold 7 psi for 10 minutes?

When you tested it did you flex the carb boot?

Sometimes the boot tests ok, but when you hang a carb on it and give it vibration a crack can open up and leak.

When you tested it did you flex the carb boot?

Sometimes the boot tests ok, but when you hang a carb on it and give it vibration a crack can open up and leak.

What were the results of the leak down test, did it hold 7 psi for 10 minutes?

it was real close after 10 min it was at 6.5psi:-/

did not flex carb boot

it was real close after 10 min it was at 6.5psi:-/

Psi should not drop, you still have an air leak somewhere.

Slick recommends 5 mins, but I like the feeling of 10mins.

When the exhaust pipe is fitted is there a leak at the flange?

Last edited:

Dam! well what areas do you check i checked the cylinger base head reeds which was where ONE of my leaks was crap i never checked the exhaust to see if i had a good seal there.

Similar threads

- Replies

- 0

- Views

- 79