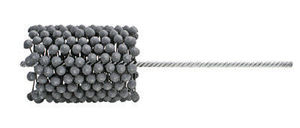

On the website for the flex hone manufacturer, they list a 67mm flex hone, but for all the Canadian distributors websites, they jump from a 64 to a 70 and they say to choose the next bigger size of the bore.

Would I be ok using a 70mm hone for a stock 66 bore? How much flex is in a flex hone? If I have to special order a 67 from the states, it's gonna cost me almost double. Yikes!

Also, should I get 240 or 320 as a finish grit?

Would I be ok using a 70mm hone for a stock 66 bore? How much flex is in a flex hone? If I have to special order a 67 from the states, it's gonna cost me almost double. Yikes!

Also, should I get 240 or 320 as a finish grit?