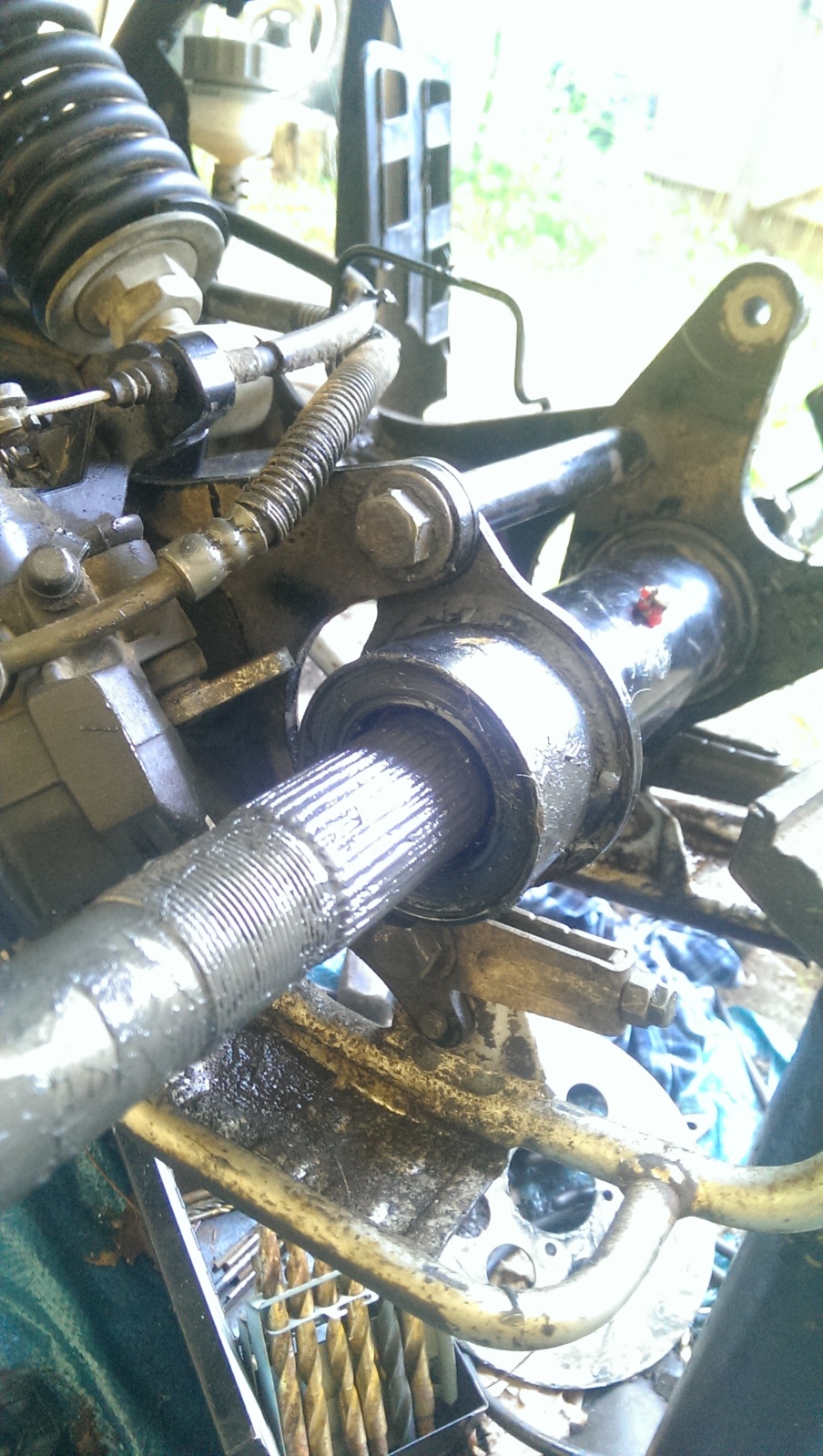

My plan of attack when all else fails, is to put a small cutting disk into the dremel and remove a slice of the outer bearing, if you do cut a little into the carrier, as long as it does not go through to the outside it will be fine.

Try not to damage where the oil seal will sit, and all will be fine.

This is a scenario where backyard science may have to rear it's ugly head!

Try not to damage where the oil seal will sit, and all will be fine.

This is a scenario where backyard science may have to rear it's ugly head!