There seems to be interest in the strength of Forged vs. Cast Pistons. I didn’t have a cast piston to crush in the press for a demonstration, but we’ve all seen enough carnage and know how cast pistons fly apart.

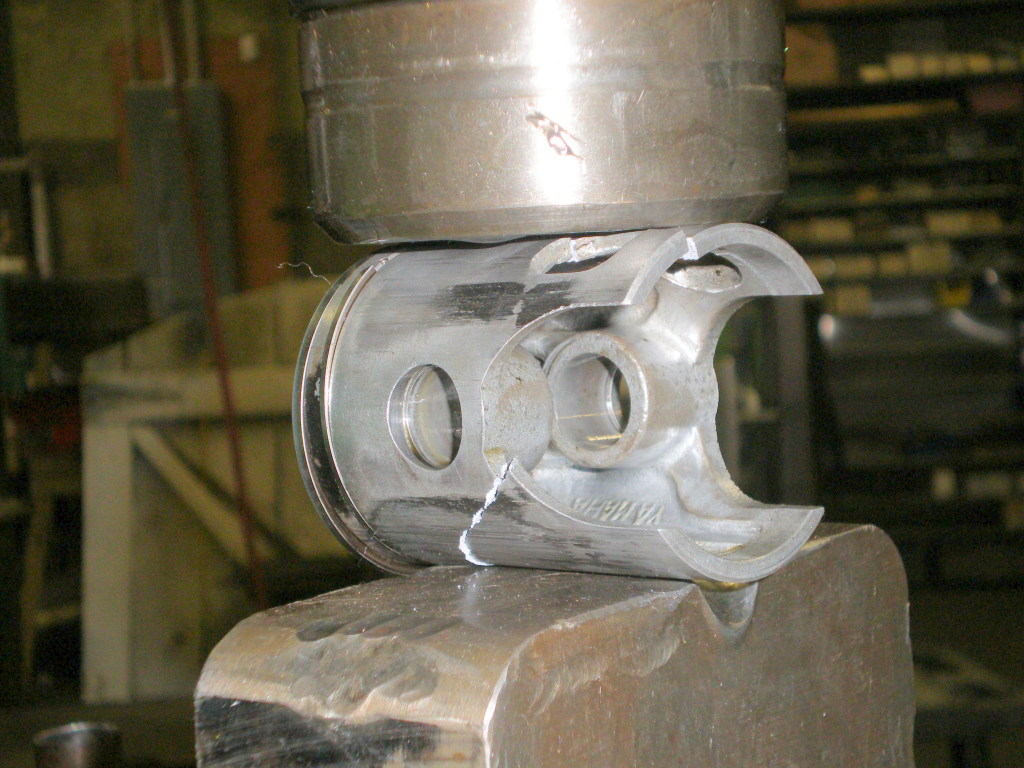

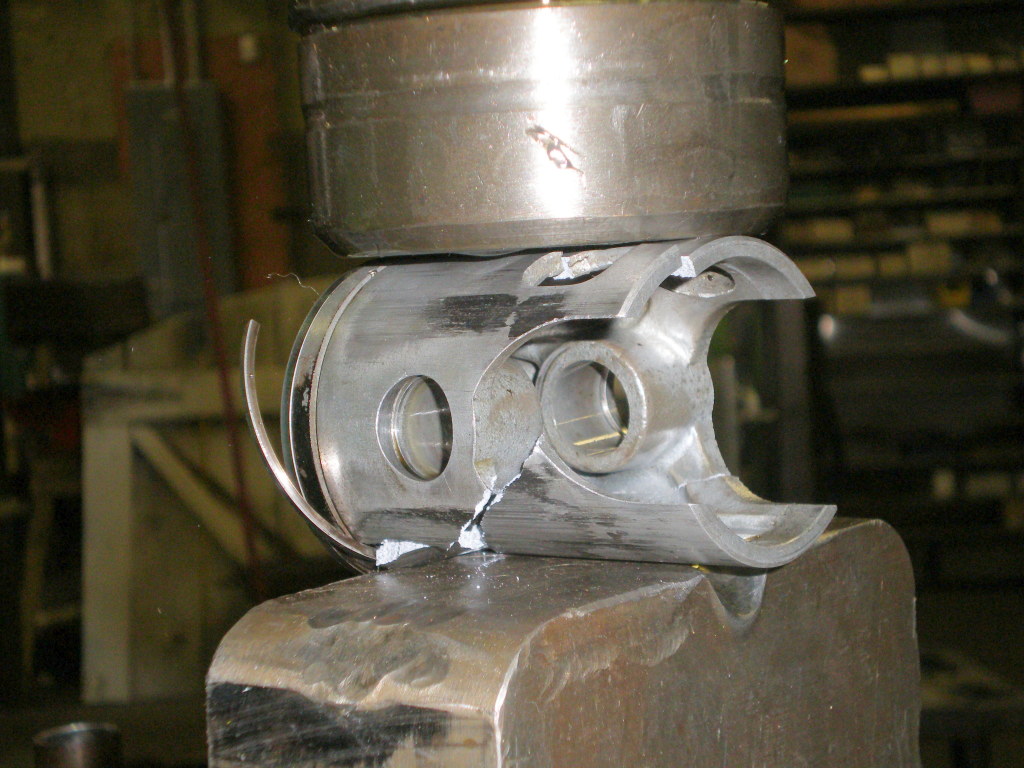

I did find an old forged Wiseco to give a substantial push demonstration. I put this old Trooper Wiseco in my 60 ton press and gave it a shove. The piston didn’t start to fail till around 40 tons. I took these photos at 50 tons of pressure.

2 Views of the same Piston after a 50 ton push

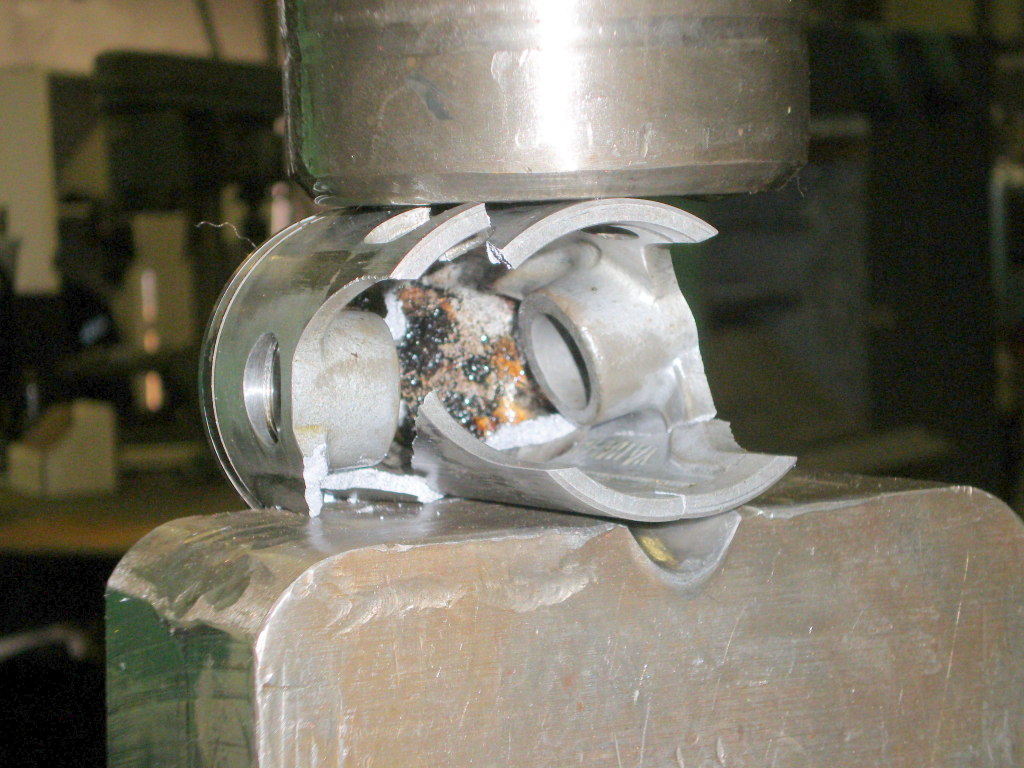

CAST PISTON:

My large press was a little over kill for the Yamaha piston. The piston started to crack almost instantly. I wasn’t able to get any kind of pressure reading

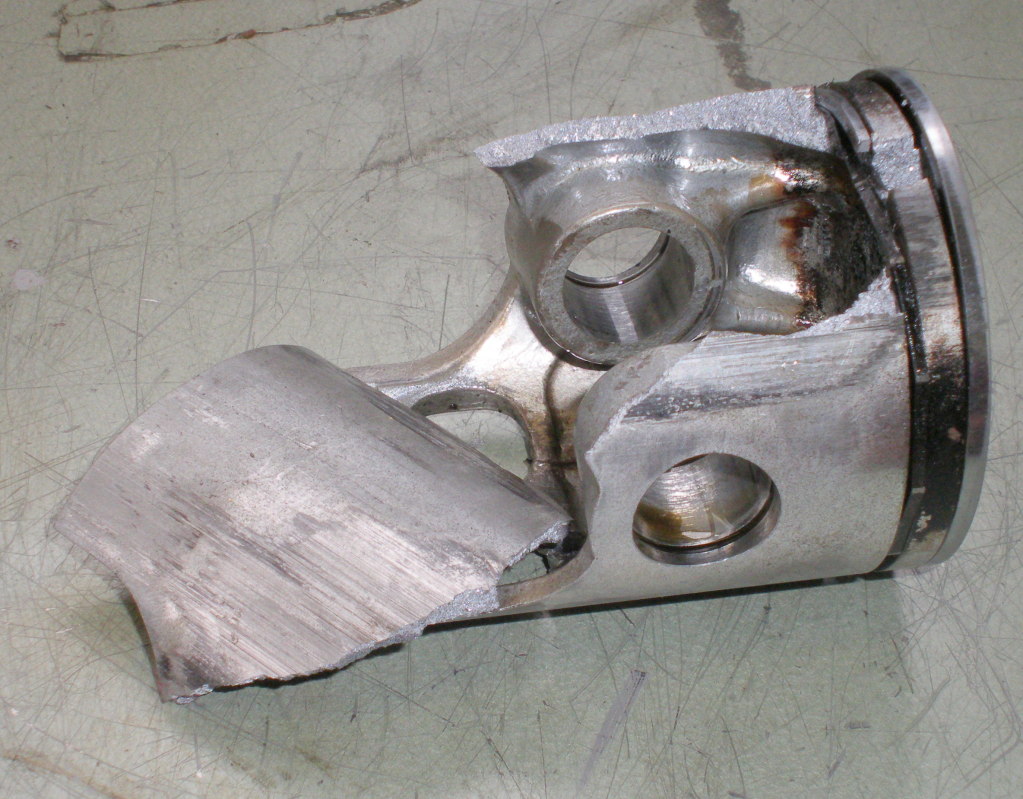

The pair: Small, Yamaha Cast

Large, Forged Wiseco.

Not much needs to be said after a look at the pics. This is a total guess but it seems as though the forged piston is 5-10 times stronger than the cast piston. This shows you folks the true story between Cast & Forged pistons.

I give Wiseco Piston a Thumbs UP.

Credit for the write up goes to John Tice

I did find an old forged Wiseco to give a substantial push demonstration. I put this old Trooper Wiseco in my 60 ton press and gave it a shove. The piston didn’t start to fail till around 40 tons. I took these photos at 50 tons of pressure.

2 Views of the same Piston after a 50 ton push

CAST PISTON:

My large press was a little over kill for the Yamaha piston. The piston started to crack almost instantly. I wasn’t able to get any kind of pressure reading

The pair: Small, Yamaha Cast

Large, Forged Wiseco.

Not much needs to be said after a look at the pics. This is a total guess but it seems as though the forged piston is 5-10 times stronger than the cast piston. This shows you folks the true story between Cast & Forged pistons.

I give Wiseco Piston a Thumbs UP.

Credit for the write up goes to John Tice