Hey Blaner

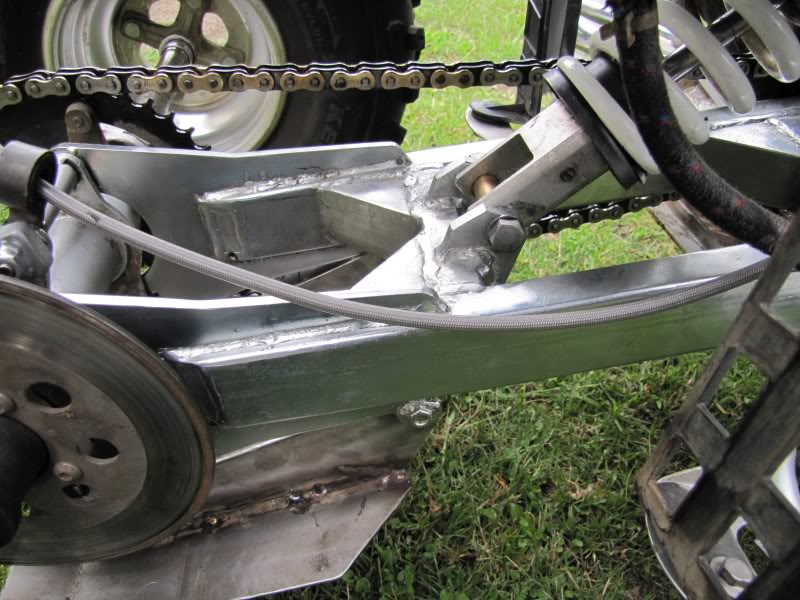

The swinger looks good, you did a good job.

When I started building mine I was also thinking of using a vesconite bush instead of a bearing. I decided to stick with the bearings did not want to take a chance. You dont have to buy the bearing from Yamaha you can get it from any bearing supplier plus it will be a lot cheaper. Let me know how the vesconite holds up.

Good job with the thread I like all the detail! I:I

The swinger looks good, you did a good job.

When I started building mine I was also thinking of using a vesconite bush instead of a bearing. I decided to stick with the bearings did not want to take a chance. You dont have to buy the bearing from Yamaha you can get it from any bearing supplier plus it will be a lot cheaper. Let me know how the vesconite holds up.

Good job with the thread I like all the detail! I:I