Well my swingarm cracked, its rusty inside and since I extended it and put the banshee 2+2 axle in its been having a hard time and showing some metal fatigue.

I decided to construct a new one...if you look here: http://www.blasterforum.com/suspension-14/rear-suspension-geometry-new-swingarm-44893/#post560668 you will see i did some geometry homework before I started...

anyway, my needle rollers and bushes were worn pretty bad, and since they cost and arm and 2 legs, i made another plan to get another life before having to buy new rollers and tubes.

I got a guy to turn down the inner tubes to get rid of the pitting and then to make me matching vesconite bushes instead of the needle rollers...

While he was at it i got him to make me some tubes for the swingarm setup, they are a custom size and you cant purchase the correct size pipe from the shop.

here they are...

When these wear out, i will get new tubes and needle rollers from yamaha.

Then i got some of this: 50x25x2mm

and this:

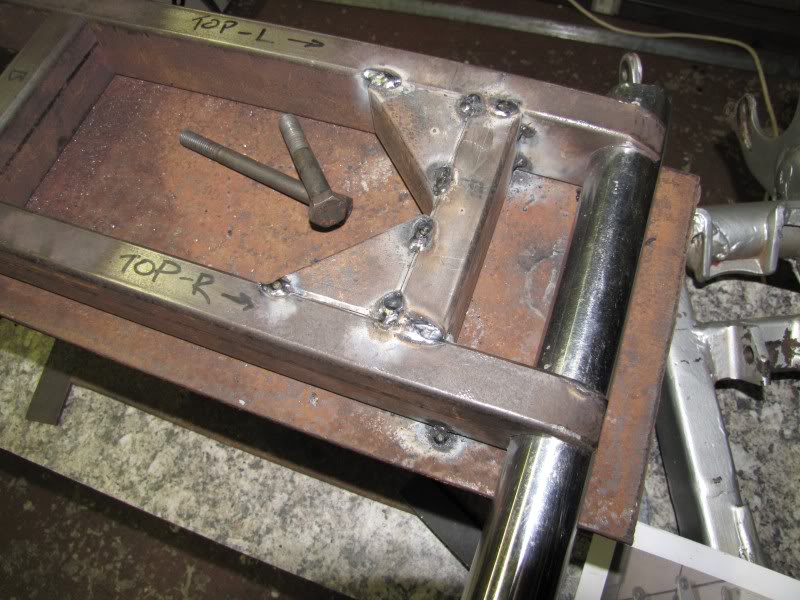

and I also got some 40x40x6mm angle iron and made these:

Then I cut these and measured and drilled and hacksawed and filed untill I had this:

You can see i have worked the one but not the other...this was to that I could do this:

I decided to construct a new one...if you look here: http://www.blasterforum.com/suspension-14/rear-suspension-geometry-new-swingarm-44893/#post560668 you will see i did some geometry homework before I started...

anyway, my needle rollers and bushes were worn pretty bad, and since they cost and arm and 2 legs, i made another plan to get another life before having to buy new rollers and tubes.

I got a guy to turn down the inner tubes to get rid of the pitting and then to make me matching vesconite bushes instead of the needle rollers...

While he was at it i got him to make me some tubes for the swingarm setup, they are a custom size and you cant purchase the correct size pipe from the shop.

here they are...

When these wear out, i will get new tubes and needle rollers from yamaha.

Then i got some of this: 50x25x2mm

and this:

and I also got some 40x40x6mm angle iron and made these:

Then I cut these and measured and drilled and hacksawed and filed untill I had this:

You can see i have worked the one but not the other...this was to that I could do this: