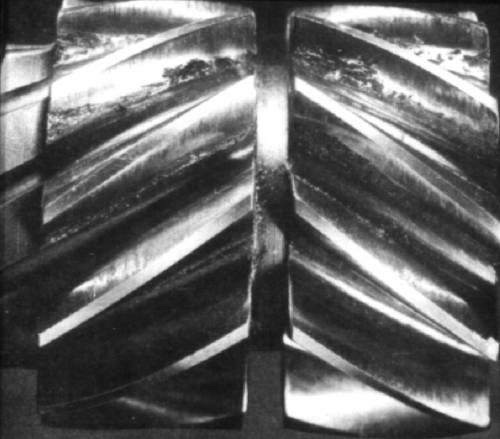

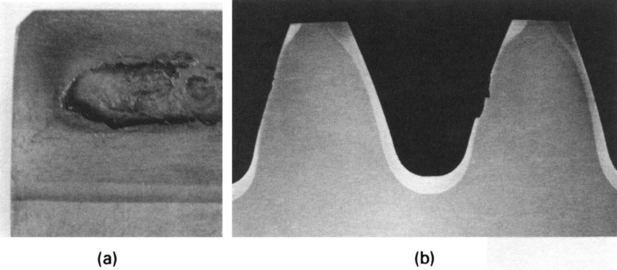

So i've just inspected my transmission as i started to rebuild the motor and i have found an issue. The teeth on one of the sliding drive gears have odd marks which almost looks like they haven't been engaging properly as the marks are on most of the teeth on the gear. Also there are the same sort of marks on the tips of other gears which i think may be down to violent, clutch less shifting. Both types of marks are visible in the pics.

Im pretty sure i will need to replace this gear and therefore the c-clips that hold the gears on.

looking for some advice on what may have caused these marks?

Also, The gear that engages with this one has none of the marks mentioned and looks to be in good condition.

Im pretty sure i will need to replace this gear and therefore the c-clips that hold the gears on.

looking for some advice on what may have caused these marks?

Also, The gear that engages with this one has none of the marks mentioned and looks to be in good condition.