hey guys, and girls??

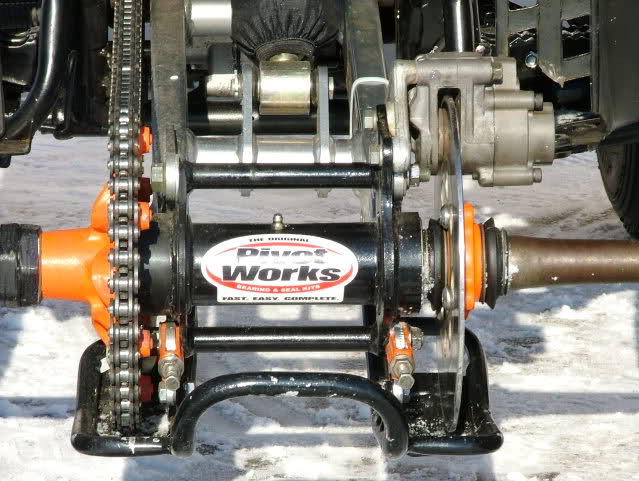

does anyone see a problem with me drilling some holes in the bearing spacer, that the axle goes thru, to allow grease to get in there, to keep water out, i just received my new bearings and seals today, and added a grease fitting to the axle carrier, and remember reading that you should remove the inner bearing seal to allow the grease from the zerk to get into the bearing from inside, but it looks like this spacer may limit this, so had a brainfart to drill some holes in it??? good idea or not????

does anyone see a problem with me drilling some holes in the bearing spacer, that the axle goes thru, to allow grease to get in there, to keep water out, i just received my new bearings and seals today, and added a grease fitting to the axle carrier, and remember reading that you should remove the inner bearing seal to allow the grease from the zerk to get into the bearing from inside, but it looks like this spacer may limit this, so had a brainfart to drill some holes in it??? good idea or not????