almost there...

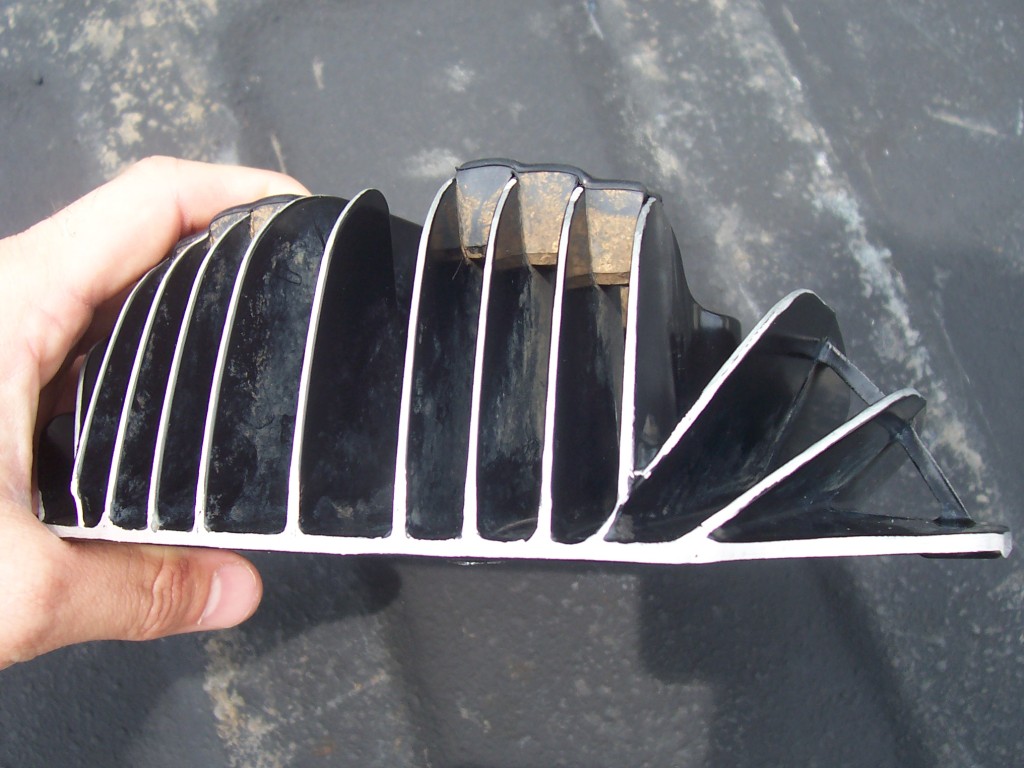

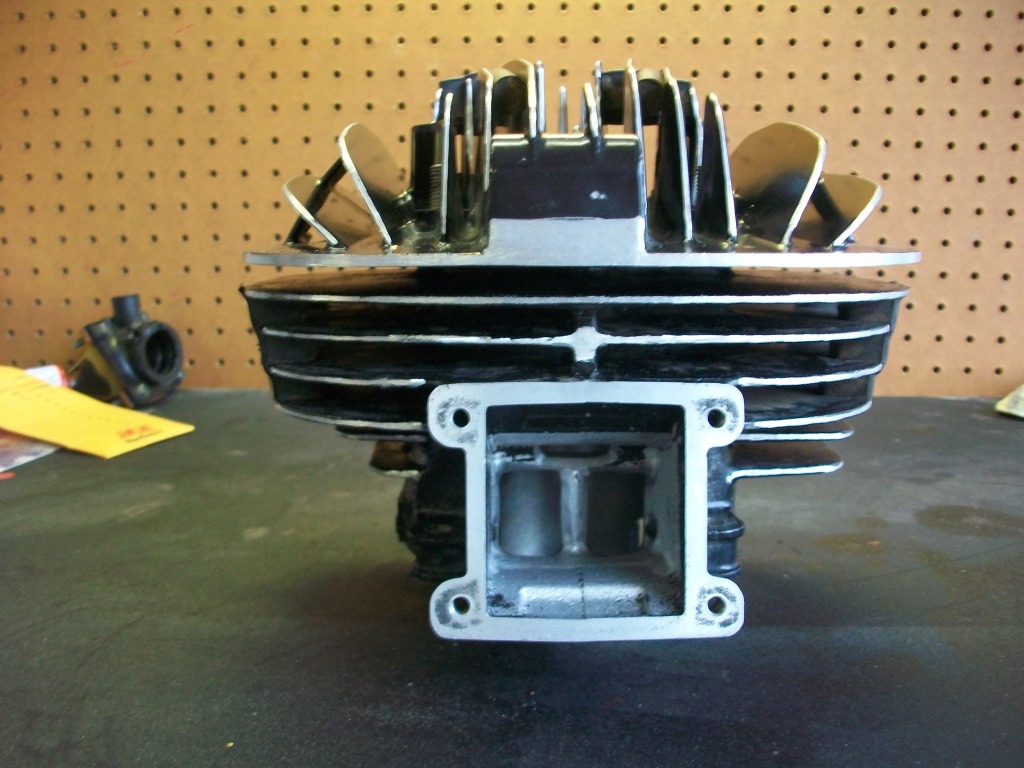

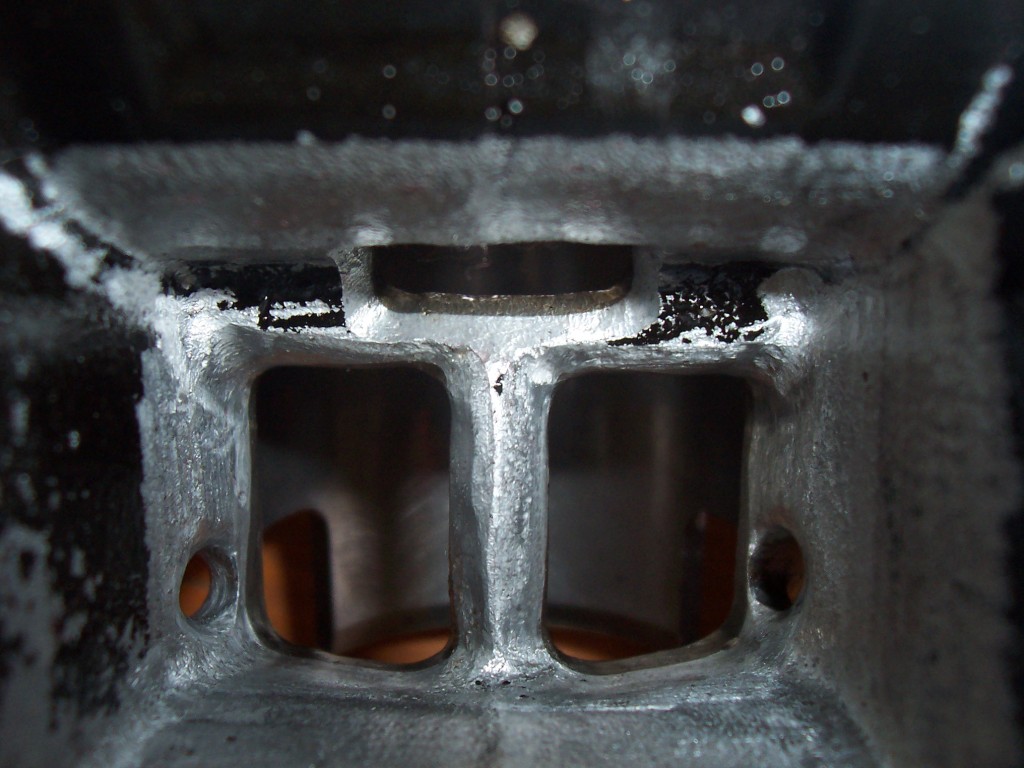

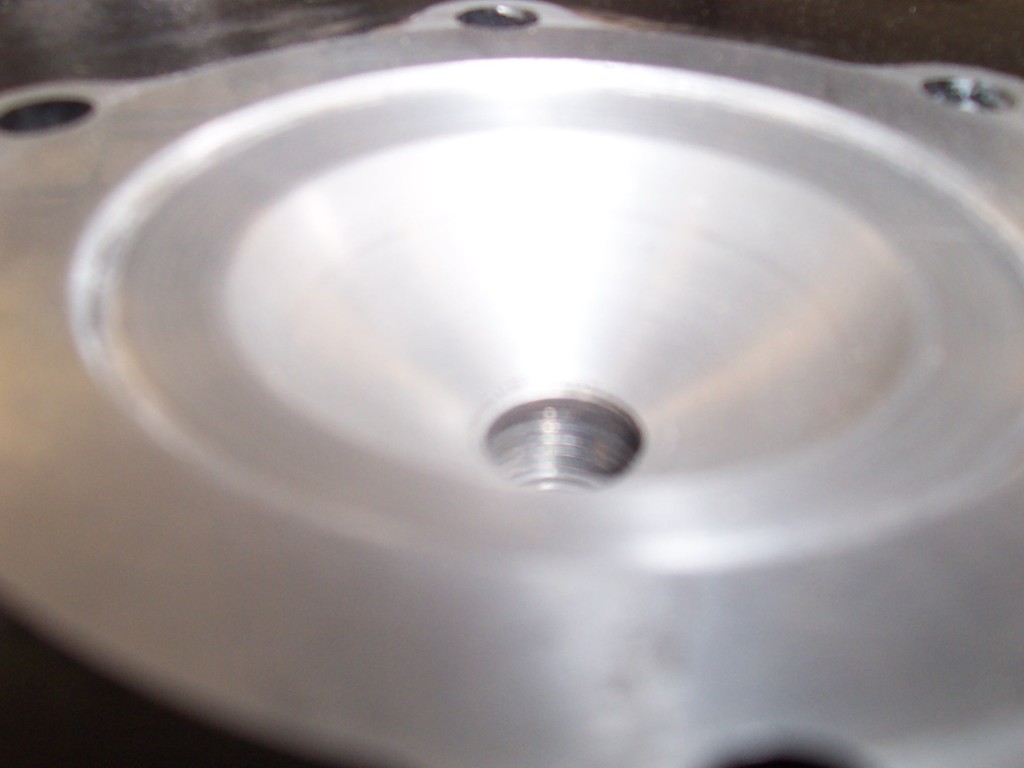

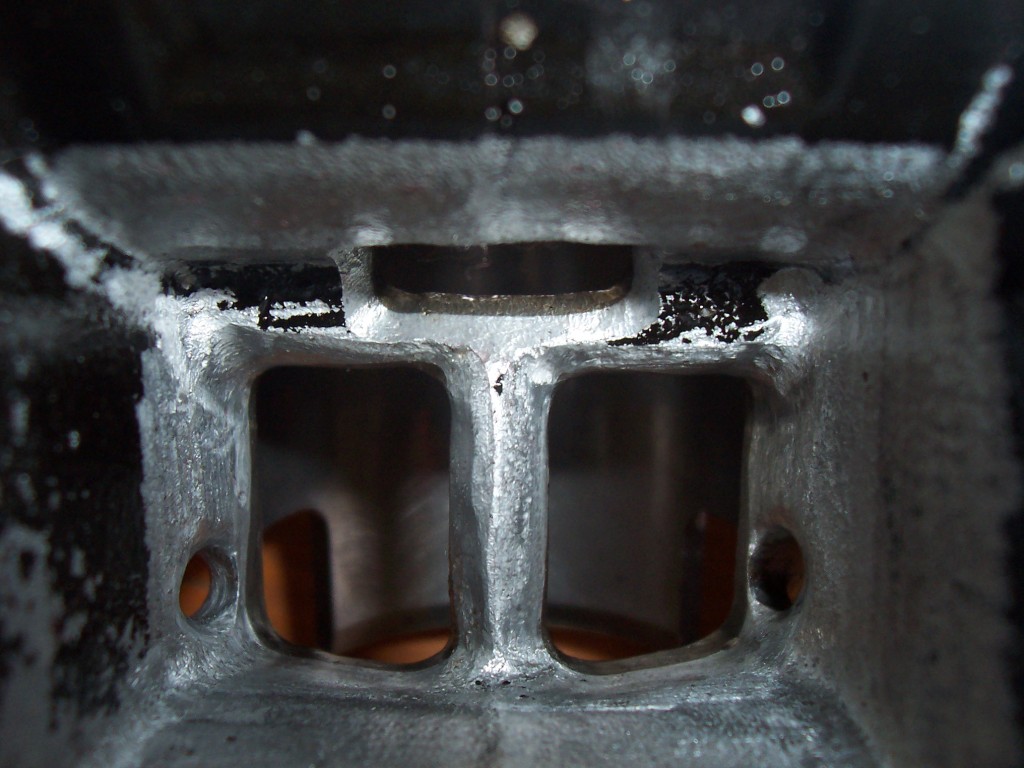

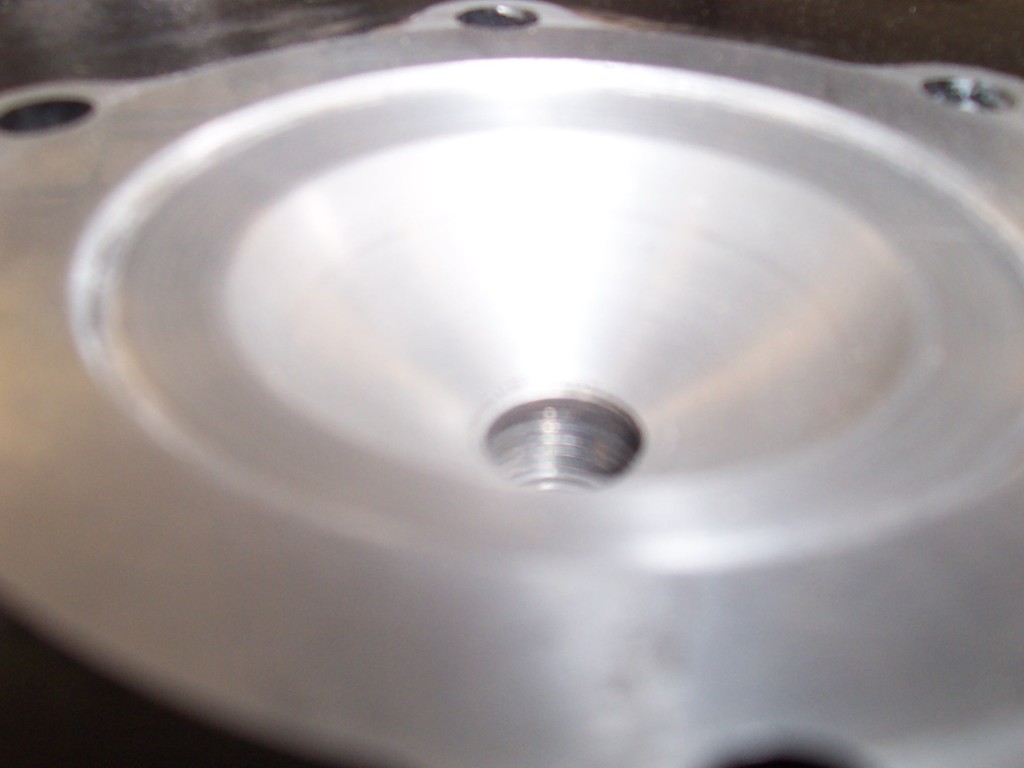

i know james posted pics already, but they just do not do this port work any justice. it is just amazing to me. everything is uniform in it. just top notch in my book. gonna start on it tonight assembling and getting a clutch pack installed and my stator and flywheel put in.

i know james posted pics already, but they just do not do this port work any justice. it is just amazing to me. everything is uniform in it. just top notch in my book. gonna start on it tonight assembling and getting a clutch pack installed and my stator and flywheel put in.