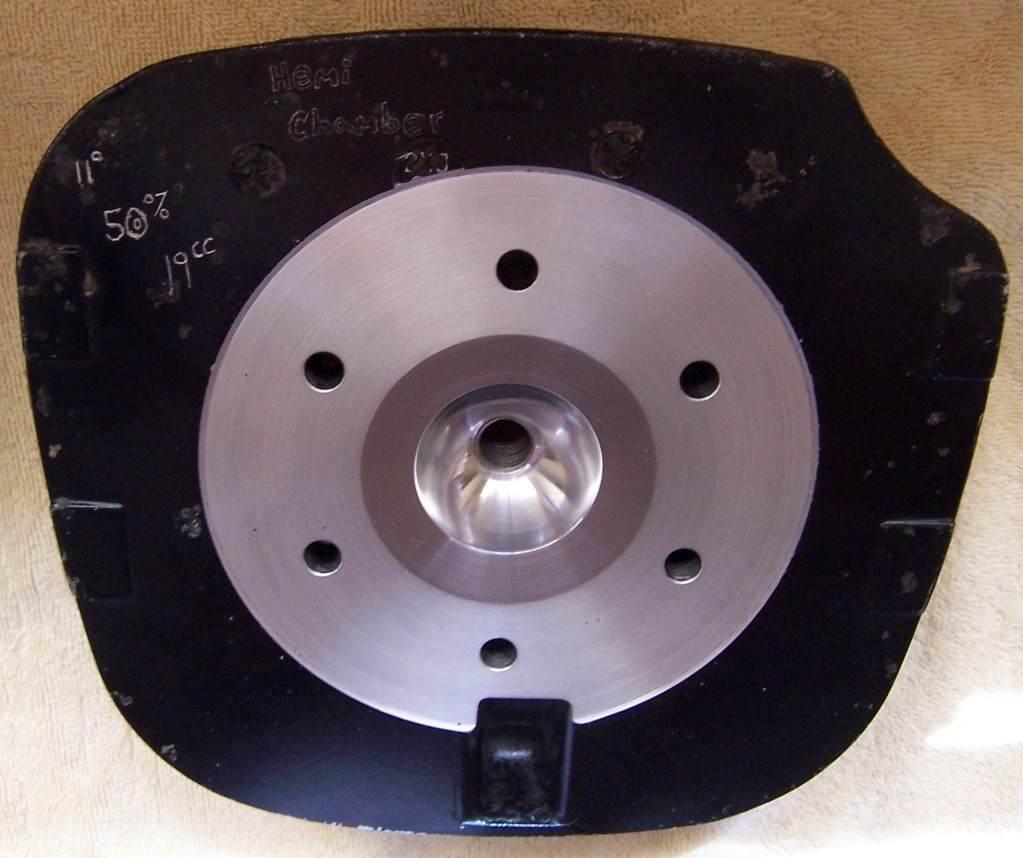

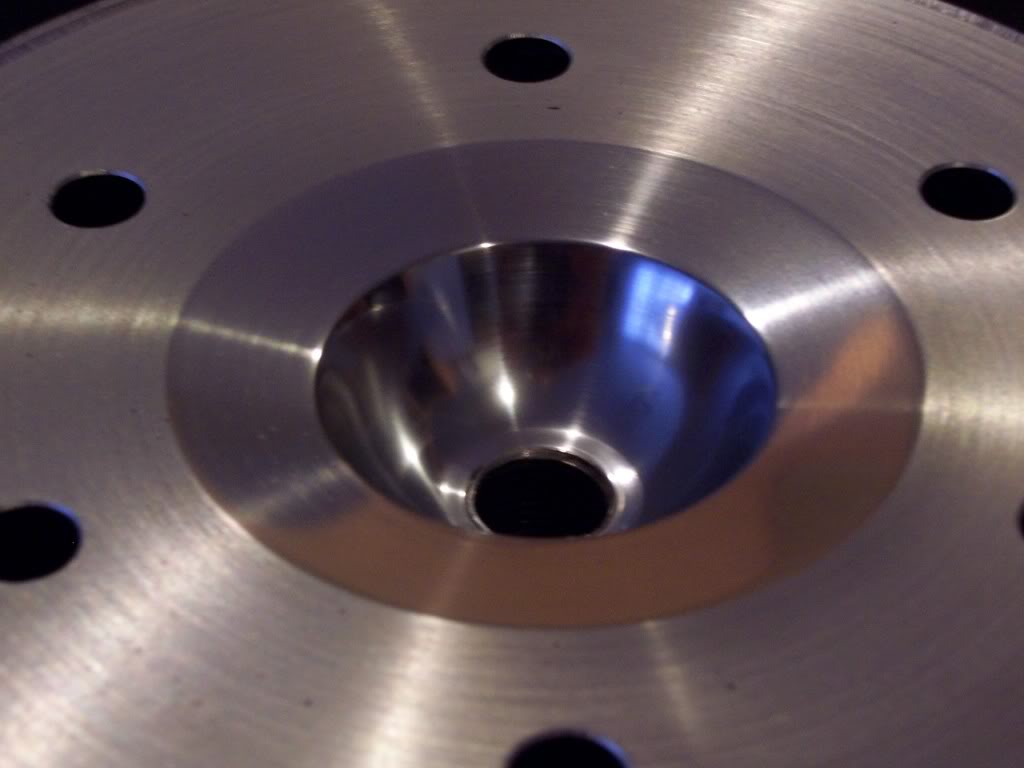

Hey there fellas, I am a lifelong dirtbike guy who has recently decided to branch off into a quad, originally mostly for my daughters' benefit as they needed something they were comfortable riding and I am always happy to spend money on new toys. I picked up an 04 Blaster pretty reasonable and after spending a bit of saddle time on it myself I naturally want to massage a lil' more ummpphhh out of it soon. Not planning anything too fancy..just a new top end, DMC exhaust and jetting specs and am also wanting to have the head milled and reworked by reputable and experienced Blaster aftermarket shop to raise the compression some and create a more efficient combustion chamber. I know there is some more juice in that motor as it is in a pretty mild state of tune from Yamaha. Seeing as the Blaster motor is nothing more than an ol' IT 200 powerplant, I know they can have a bit more coaxed out of them rather easily. Any suggestions on the headwork would be greatly appreciated.

Thanks a bunch in advance.

Thanks a bunch in advance.