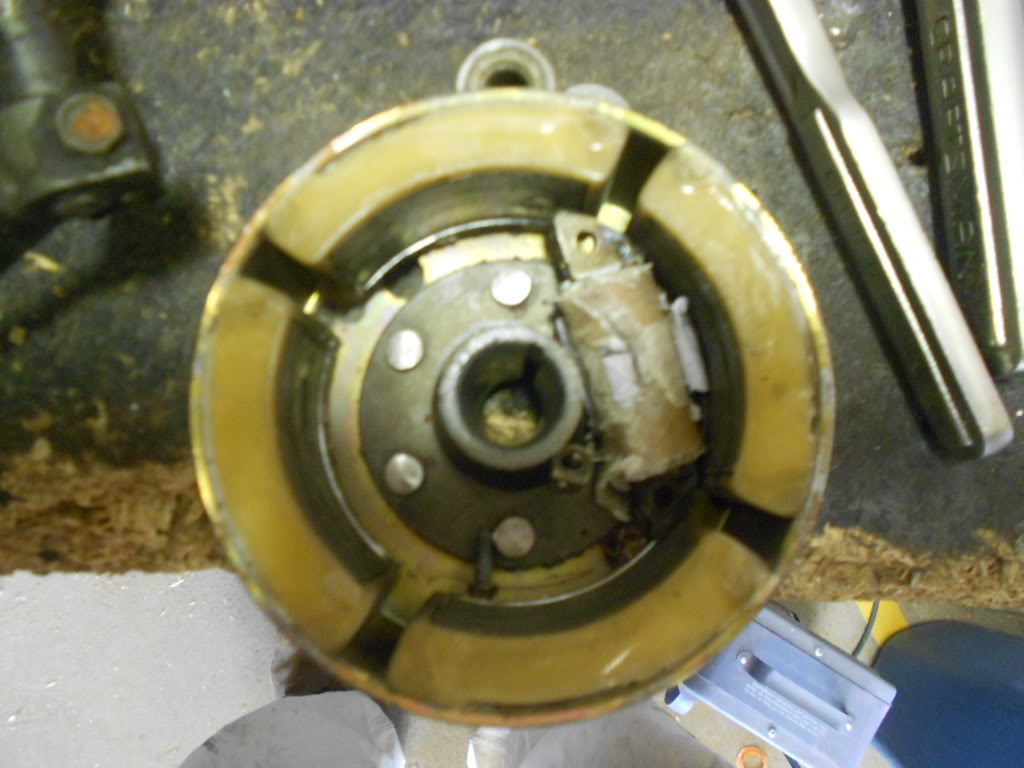

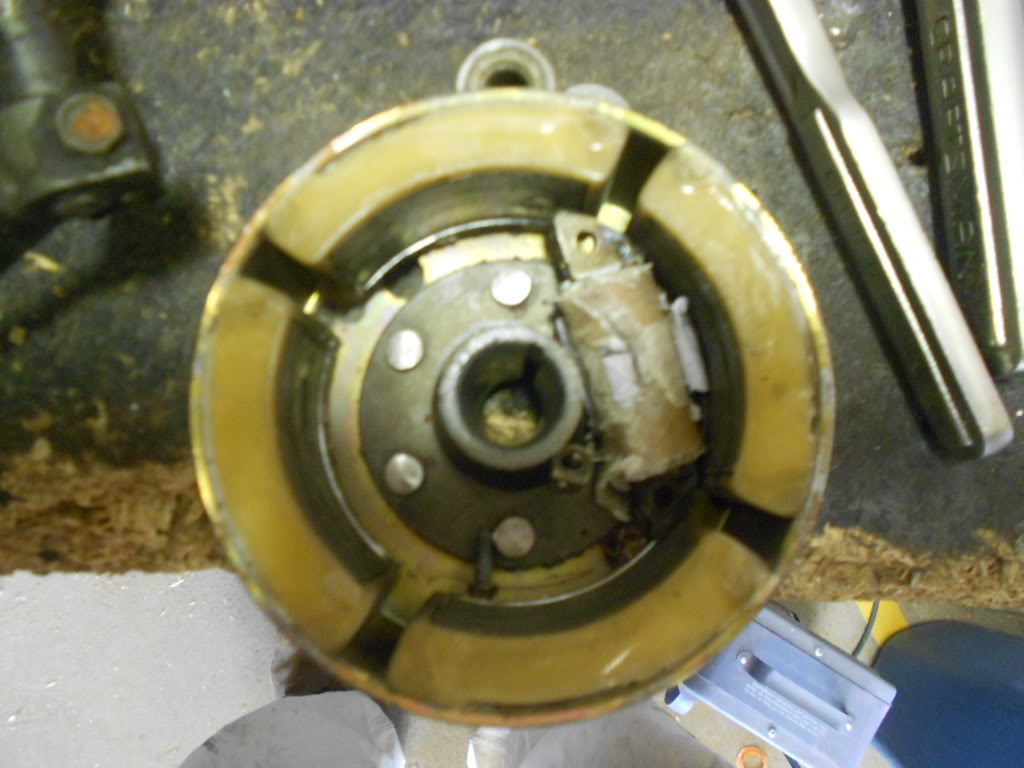

That is much too smal to be the key. It may me one of the pickups though. I bought one for $250 that had one of the pick ups come loose. it was jammed in there pretty tight and would not let the crank turn a full revolution. When you open it check to see if the woodruff key has been shearded off mine was.