ive been searching for some parts to build a anti-vibe stem instead of having to take pieces to a machine shop and so far i have found only one place that will sell the 2 machined pieces that the clamp bolts too and lonestar racing will sell just those pieces and they are 8 bucks a piece, not too bad if you ask me. so if anybody else knows any places that u can buy some stem parts to help others out in the search, post up the website here and make it easy for someone else. maybe some guys that are experienced in this can post up some measurements of the outside diameters of the stock stem and what gauge metal would be best, and some tube lengths for different sizes like +1 or +2 etc. or just any tips that u may have come across to make it easier for the next man. im just starting to build my stem so when i get done i will come back and add some tips along the way and some measurements. this thread should make it easy for someone else to build a stem without a bunch of questions so post up!! im also looking for a place to buy the stem flag that the tie rods bolt too instead of cutting the one off my stock stem so if u know that place hook a brotha up!!

2 machined pieces that the clamps bolt too-- Lonestar Racing $8 a piece

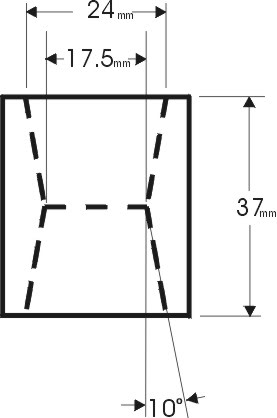

tubing size is 1 1/4 OD Chromoly and wall .058 about $3.69 FT at wicks metal

2 machined pieces that the clamps bolt too-- Lonestar Racing $8 a piece

tubing size is 1 1/4 OD Chromoly and wall .058 about $3.69 FT at wicks metal

Last edited: