Hey thanks man! Stay tuned, I should have more pics by tuesday and hopefully have it finished by sometime this week.

craigslist deal of the day!

- Thread starter KTM RACING 559

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hey thanks man! Stay tuned, I should have more pics by tuesday and hopefully have it finished by sometime this week.

Any update?

.

.

.

.

.

Well, its been awhile since Ive had some free time at the shop and i had some time today, so here's an updateI:I

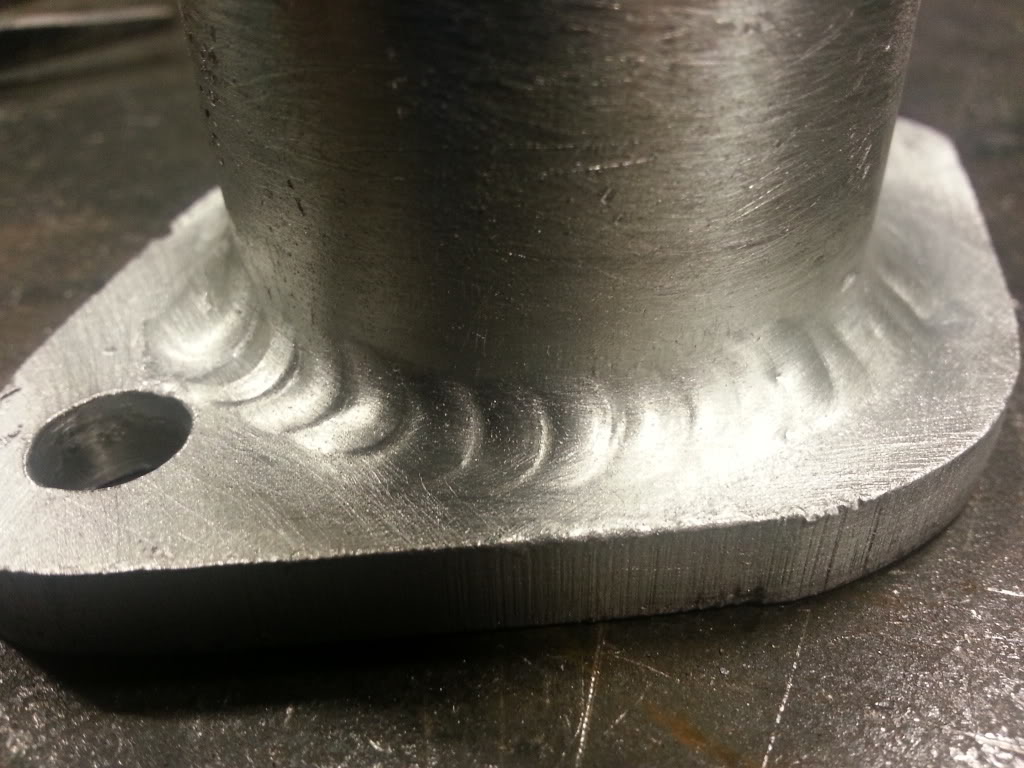

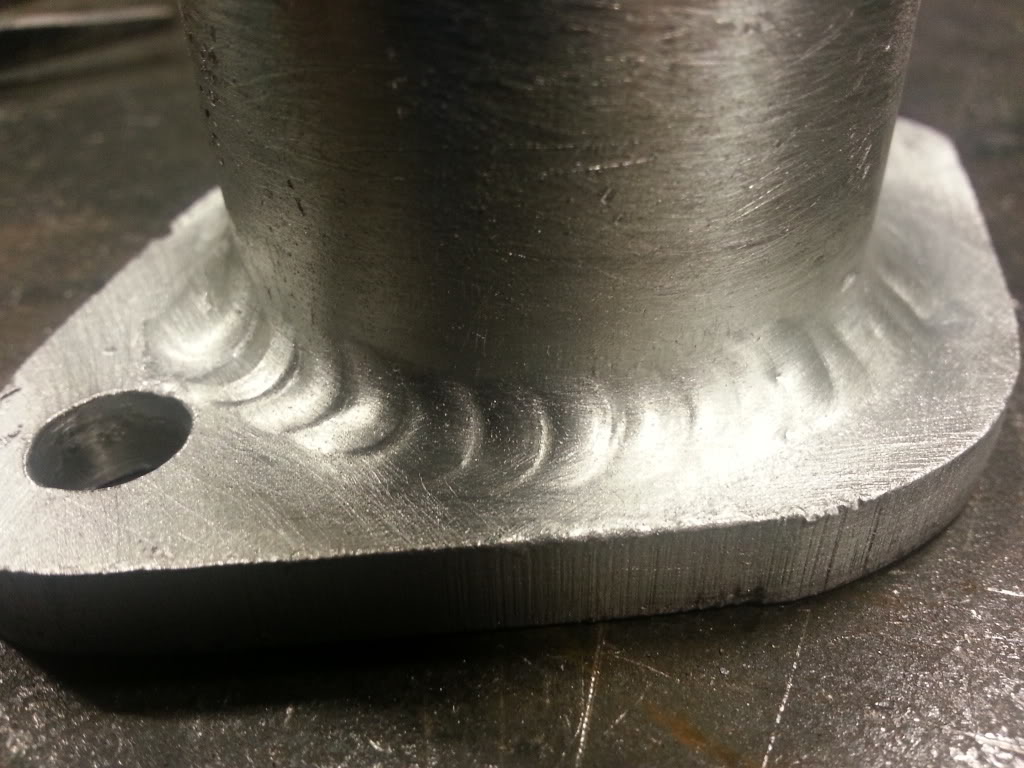

Got the tubing and and base plate ready to weld.

Tig welded it using a Lincoln Electric Precision Tig 225.

Im gonna mill the hole in the center and make a tab for the pipe spring, and the flange should be done by the end of the week if I have enough time.

Got the tubing and and base plate ready to weld.

Tig welded it using a Lincoln Electric Precision Tig 225.

Im gonna mill the hole in the center and make a tab for the pipe spring, and the flange should be done by the end of the week if I have enough time.

Nice find and awesome job on the fan work! I recently picked up a tig welder, wire feed, but have no experience at all welding. Gotta get ahold of some scrap metals and start messing around myself, would love to be able to do some general repair and fan of my own

Looks good man,I love to see someone fabricate there own parts

Thank you! its alot of fun to fabricate stuff!

Nice find and awesome job on the fan work! I recently picked up a tig welder, wire feed, but have no experience at all welding. Gotta get ahold of some scrap metals and start messing around myself, would love to be able to do some general repair and fan of my own

Thank you! If its a "wire feed"you have, It would be a MIG/GMAW(gas metal arc welding) machine. practice makes perfect, go get some sheet metal and start layin some beads down! If you need any help or have any questions feel free to askI:I

Check out this website, I've learned some good techniques from this guy!

Welding Tips and Tricks - TIG, MIG, Stick and a pantload of other info

Nice weld there, looks evenly spread.

I myself, in the last week of my welding class, got to use a TIG welder. Its really hard to learn, but he said i could master it if we had more time.

In our metals shop we have 6 Oxy-Act stations, 6 Arc stations, and 4 GMAW (wire feed) stations. He set up the two TIG welders because 8 people needed to do GMAW in the last round.

As a final project, im building a semi with my old piston as a hood, i wanted the TIG for that but he already took them out of their places

I myself, in the last week of my welding class, got to use a TIG welder. Its really hard to learn, but he said i could master it if we had more time.

In our metals shop we have 6 Oxy-Act stations, 6 Arc stations, and 4 GMAW (wire feed) stations. He set up the two TIG welders because 8 people needed to do GMAW in the last round.

As a final project, im building a semi with my old piston as a hood, i wanted the TIG for that but he already took them out of their places

Nice weld there, looks evenly spread.

I myself, in the last week of my welding class, got to use a TIG welder. Its really hard to learn, but he said i could master it if we had more time.

In our metals shop we have 6 Oxy-Act stations, 6 Arc stations, and 4 GMAW (wire feed) stations. He set up the two TIG welders because 8 people needed to do GMAW in the last round.

As a final project, im building a semi with my old piston as a hood, i wanted the TIG for that but he already took them out of their places

Thanks! Im at my college welding shop all week, 8-10 hours a day, so the practice has definatly payed offI:I. Sounds like you have a nice shop! A semi, Thats sounds cool, have you tig welded aluminum before?

Similar threads

- Replies

- 2

- Views

- 452

- Replies

- 10

- Views

- 4K

- Replies

- 12

- Views

- 2K

- Replies

- 22

- Views

- 3K