home made tracked vehical

- Thread starter blasterkid89

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

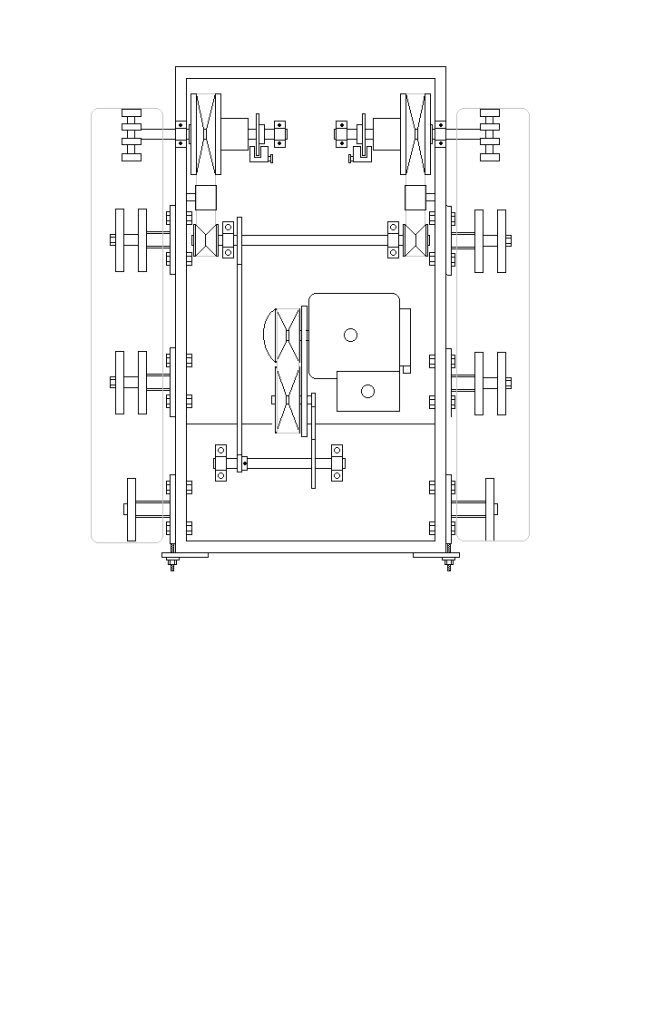

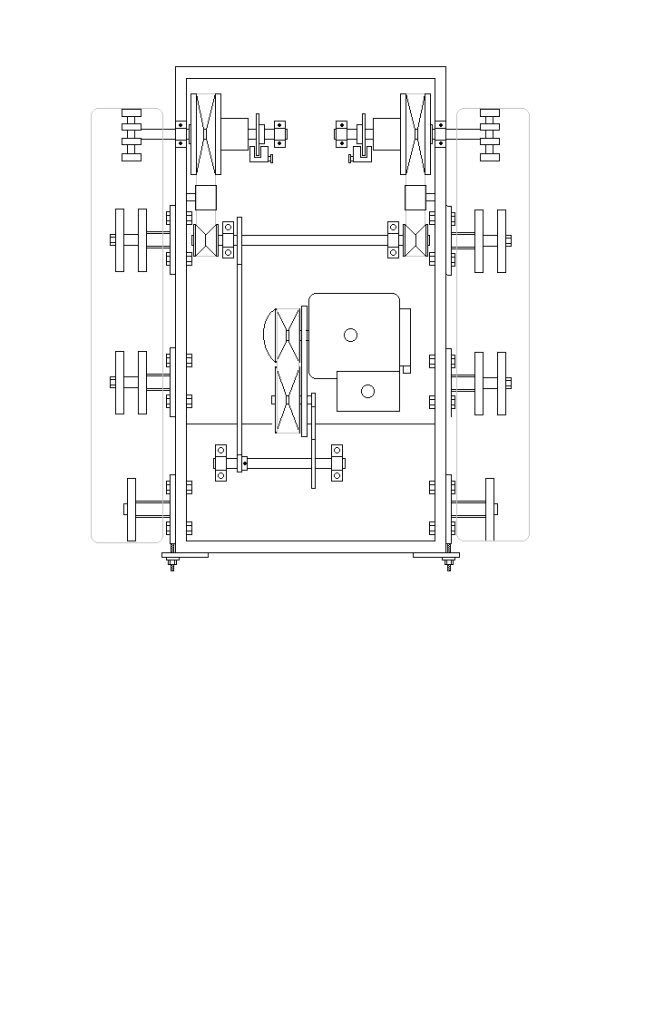

they have their own indepently driven clutches with jackshaft as apply the break on the left or right side it locks that side track up allowing for the oppiste side track to spin freely and it steeres toward that side that you lock up the track on, there will be a LH lever and a RH lever that controls that side of the machie for the breaks, then the levers u pull back pull up on that idler bully and engages that snowmobile bilt into the secondary clutch, then down to the drive axle, kinda same therory of how a dozer works

they have their own indepently driven clutches with jackshaft as apply the break on the left or right side it locks that side track up allowing for the oppiste side track to spin freely and it steeres toward that side that you lock up the track on, there will be a LH lever and a RH lever that controls that side of the machie for the breaks, then the levers u pull back pull up on that idler bully and engages that snowmobile bilt into the secondary clutch, then down to the drive axle, kinda same therory of how a dozer works

Oh okay I see now, should work pretty good than. Nice job

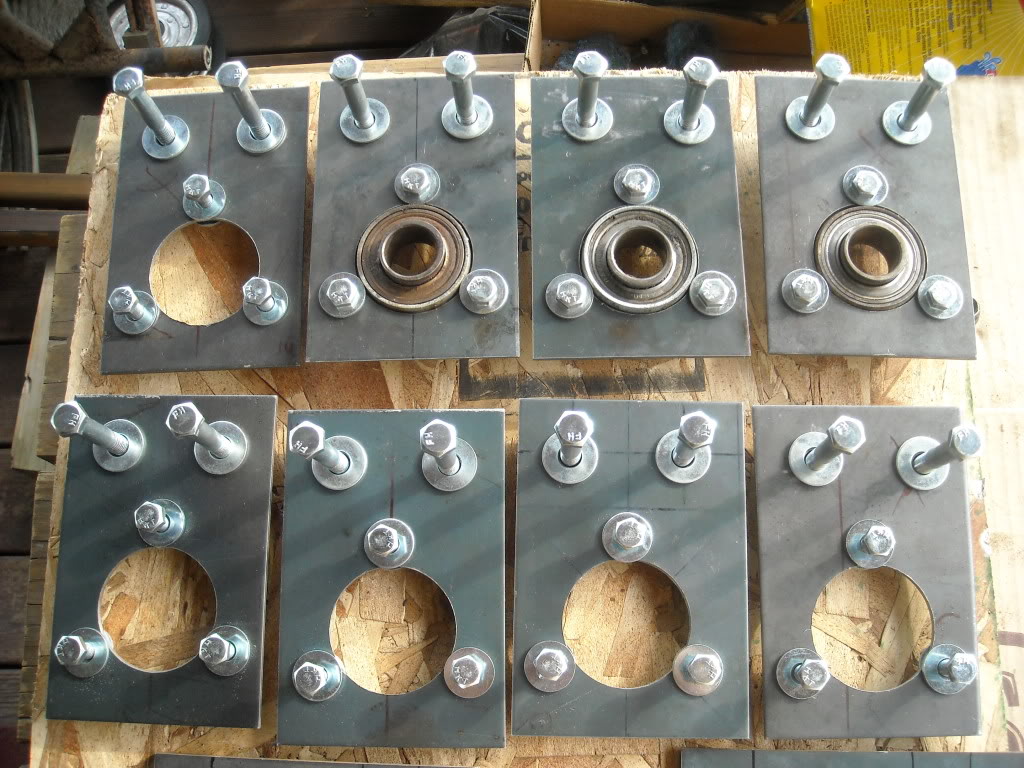

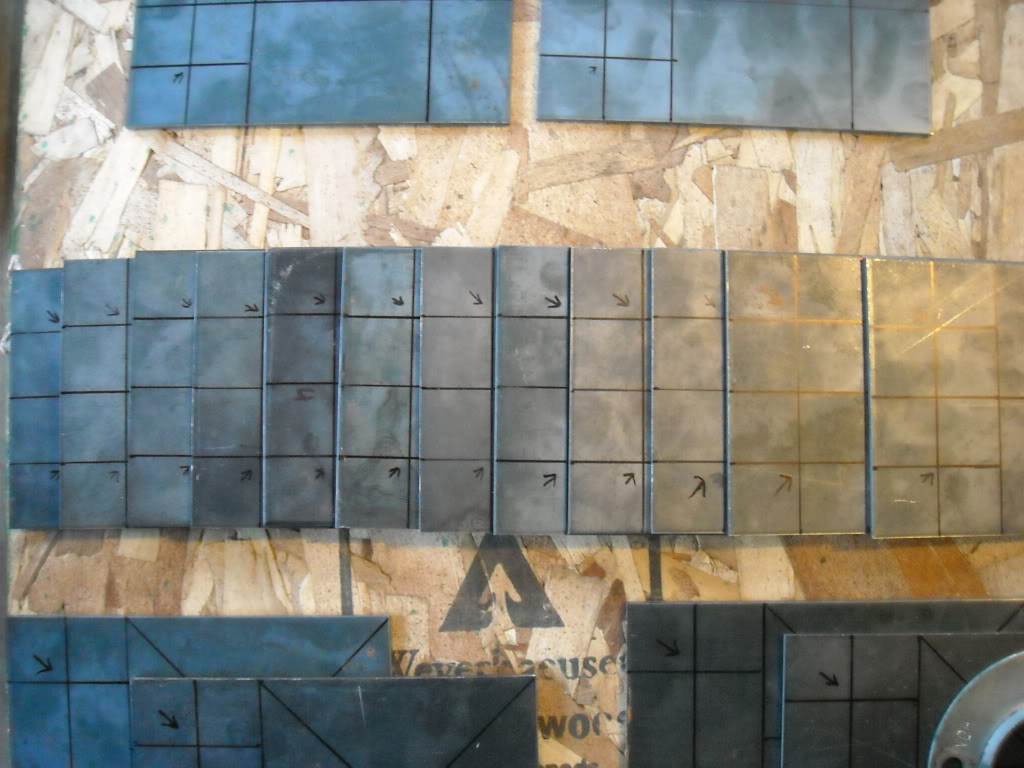

yeah it should, i got my plates all marked 8 plates are drilled for the 3/8 mountign bolts, then a 2 1/4 hole for the bearing flange, then 12 plates for the idler wheels ising 3/8" botlst to mount the plates to the side of the 1x2" tubing, and a 3/4" hold drilled in both plates for a 3/4 X8" L hex bolt to bolt the idler wheels on. marking the plates took about an hr lol

drive axle plates

Idler wheel plates

rear idler adjustable plates (2) and the other fixed idler wheel plates

drive axle plates

Idler wheel plates

rear idler adjustable plates (2) and the other fixed idler wheel plates

heres a better version i drew up of the drive train, from the torque converter system 10 tooth sprocket it well go back to a 1' jack shaft with a 30 tooth sprocket then over to a 12 tooth drive spricket then up to the front jack shaft in front ohv engine (another 30-60 tooth sprocket, then on that axle is where i can mount the 2 small drive pulleys that use a snowmobile belt

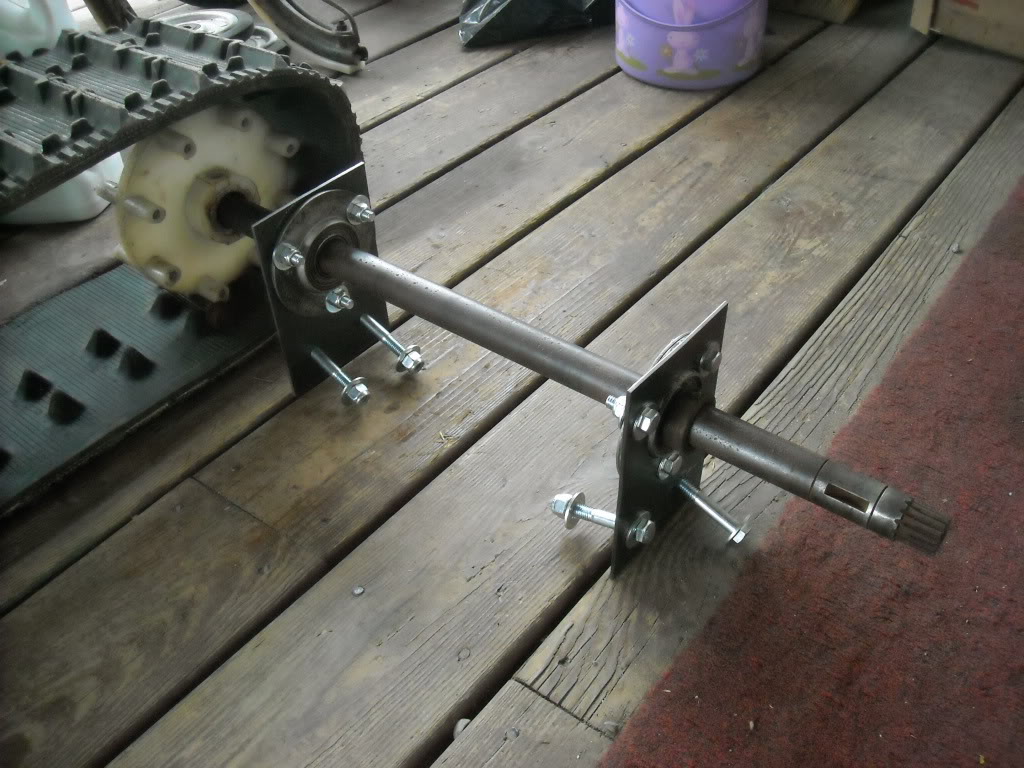

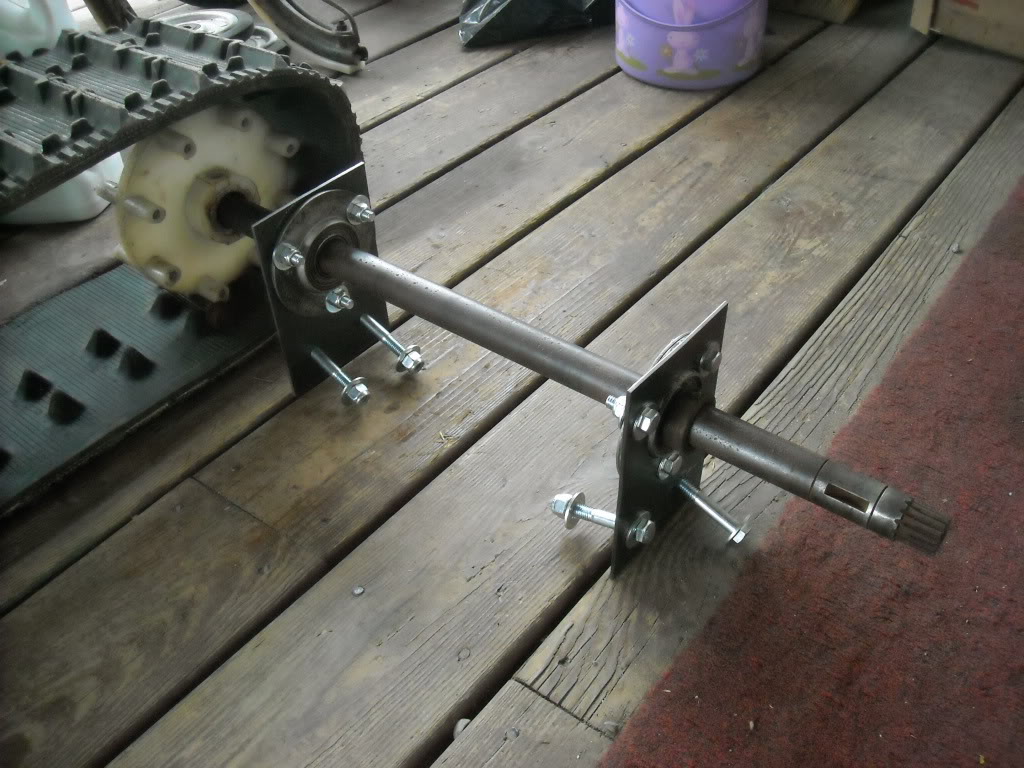

picked op $75 in hard ware tonight lol got my plates all drilled today for the brearign flanges nd frame mounts, heres a couple pics of what the idler wheel assemlies will look like but it will go trought both 1/8 plates on each side of the square toobing, and i will add the spacers and washers as well

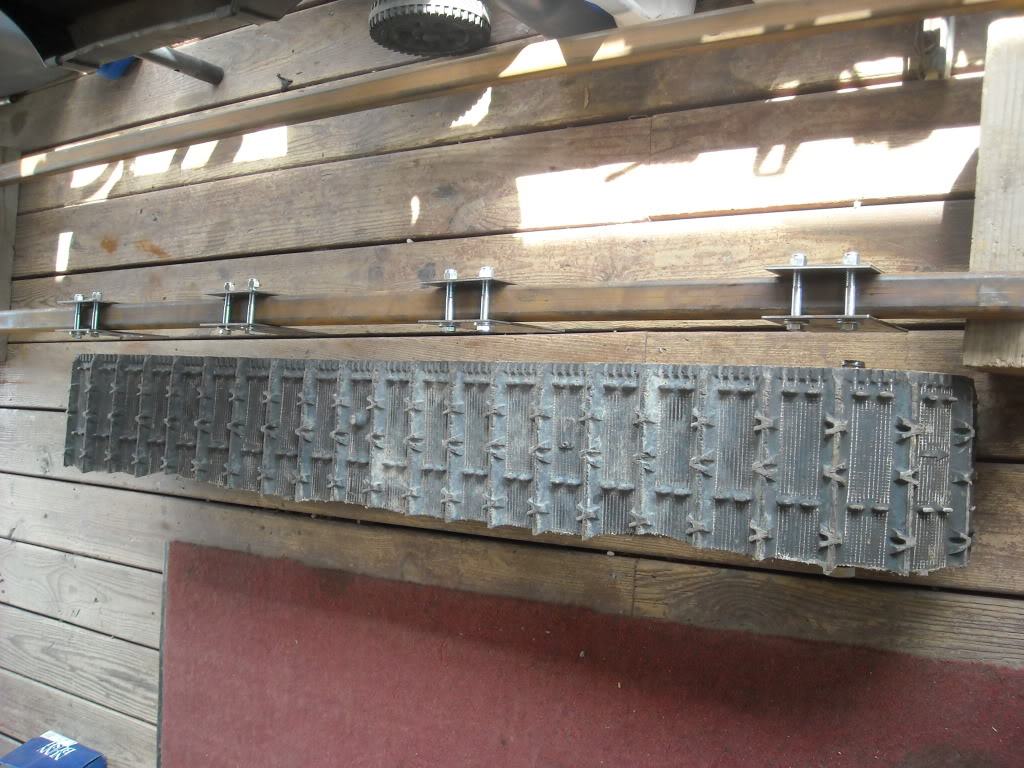

my uncle gave me 30 foot of 1 1/2" sqare tubing for free so thats what i'll use heres a couple pictures of the drive bearing hangers, then 3 idler wheel plates that will have a 3/4" hole drilled trough both the inner and outter plted then a 3/4 X 10" L bolt will go trough and connect the idler wheels to the hangers

the bolts will go trough the center of the 1 1/2" sq tubing

the bolts will go trough the center of the 1 1/2" sq tubing

Thanks yeah it seems like it took all weekend to get those plates all drilled lol, but i am hoping to have a rolling chassis done buy the end of the week all i got to to is cut the tubing to the dimensions of the frame, get the (6) 3/4" x 10 bolts, drill the bolt holes for the bearing and idler wheel hangers,, the track all adjusted, and get the drive axle on, so we'll have to see how far i get on boces this week lol, yeah im having my uncle scott keep me interested in building this so i dont loose intrest in it, lucally he onle likes liek 3 houses away and hes got most of the tools to do the jobs

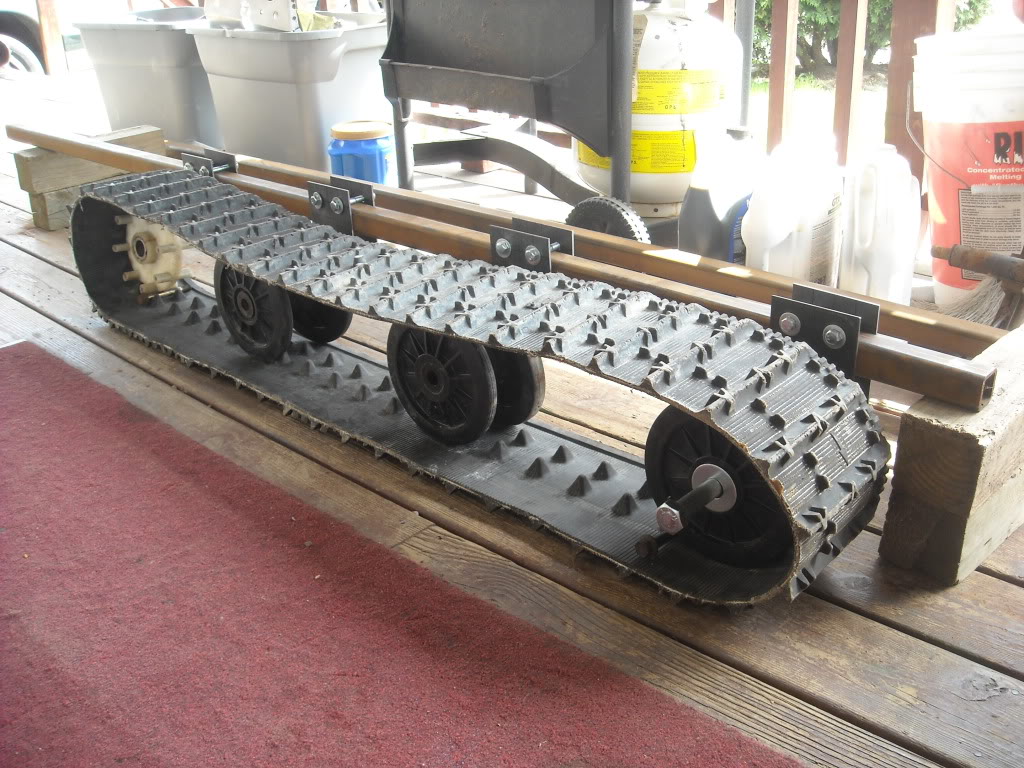

working on the lower drive axles, what it will look like but the bearing flanges will be flipped up and bolted to the frame, then i will go trought and eventuly get all new bearings

got the frame all cut on the chop saw, and two if the brackets drilled, but not welded yet grounds too unlevel, the side rails are 5ft long(need to cut extra off eventully from the back, and cross members are 3ft wide, then the 2 smaller front bearing flange mounts are 1ft long, so its getting there a little bit every day

Yeah i usually save some $ every Friday to last me for the week to tinker on it, next thing we have to do is like up the front axle up, then mount the rear idler wheel, then center the 2 sets of idler wheels on the one sided, then do the same thing on the other side, then cut the access tubing off from the rear of the machine so i can mount the rear idler wheel adjusters, then i can build up the upper jack shaft assembly and drive assembly, but first i got to make an adapter that fits inside the track drive cog that goes from 1 1/4 id to the drive axle which is 1'" OD

frames flipped up side down, but it gives ya the idea im working on lining up the rear idler wheel holes and then the 2 inside idler wheels as well

Last edited:

You're making great progress. They look like alot of fun. Be sure to post up some vids when you get it done. Keep up the good work!

Similar threads

- Replies

- 11

- Views

- 689