me and my uncle Scottie( other side of the family this time haha) well anyways we were looking on ebay for go cart parts an d we came across these plans for building ur own PTV (personal tracked vehicle) so we got to thinking and remembered that they sell go cart and mini bike parts in northern tool, and manufacture supply, we would be using snowmobile tracks and cutting the two out side bands off and using the center band that has the drive teeth in it, as far as the drive train ive got that all figured out so it has to operate like a dozer locking up each independent track when needed to turn, the motor would be a 6.5 hp OHV, its a # 41 comet clutch on the engine and a jack shaft that goes from the 10 tooth’s comet sprocket to a 20 tooth # 41 sprocket on the jack shaft then over from the other smaller 10 tooth jack shaft sprocket forward to the main 60 tooth drive sprocket that’s on the front separate drive axles, priced all the materials ect.. and its gonna cost about $600 in parts ect...

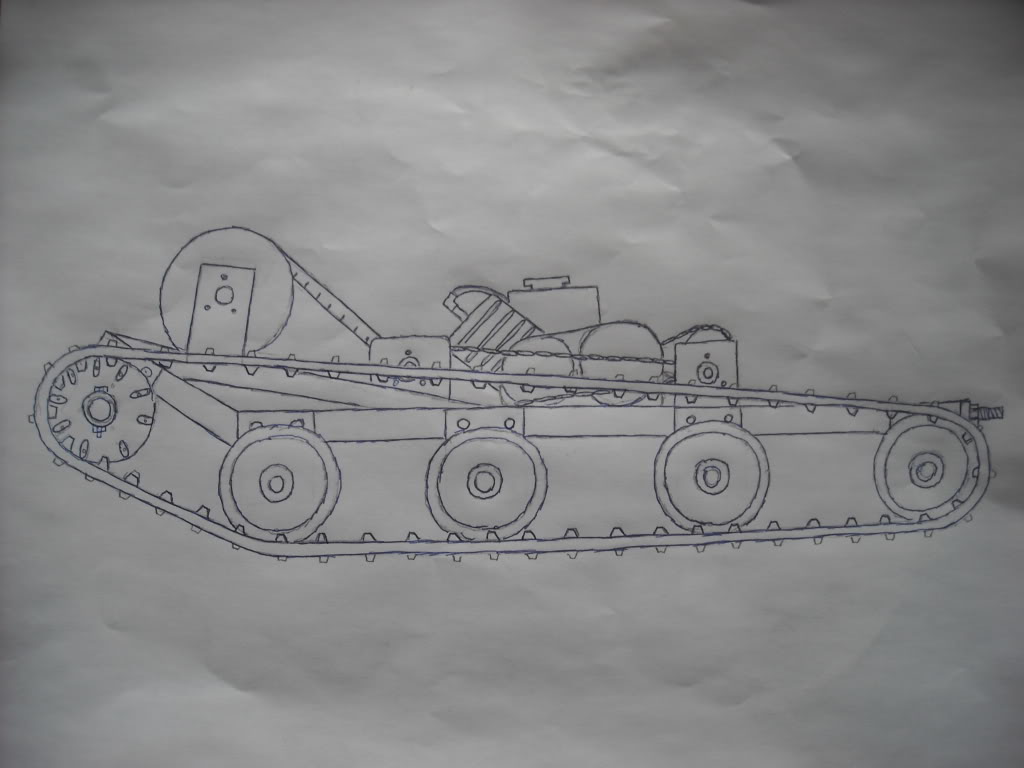

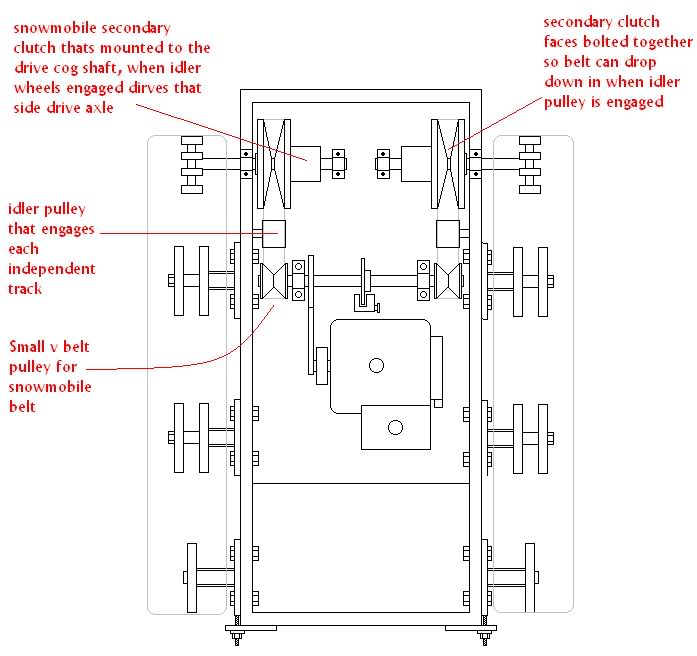

Here is a picture that i had sketched outta my head in the car one day then the other day i decided to sit down on pain and sketch it out a little neater i haven’t got went trough and priced all the drive parts with the motor, getting used tracks and idlers from a friend,and using snowmobile parts i got for free for the rest

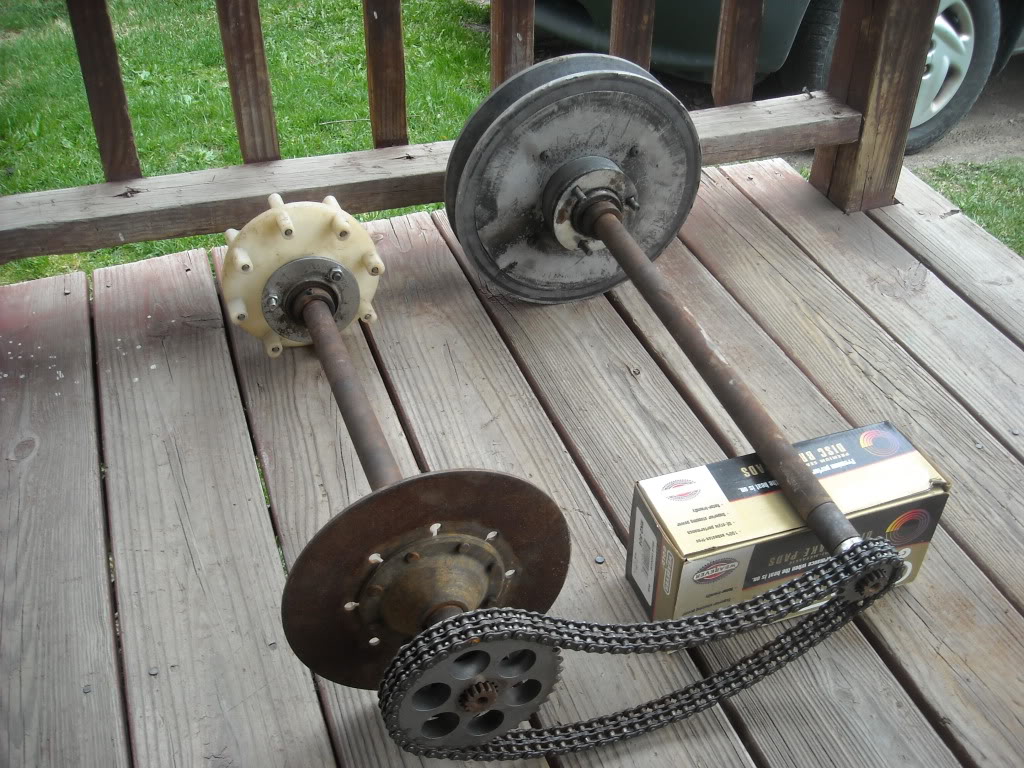

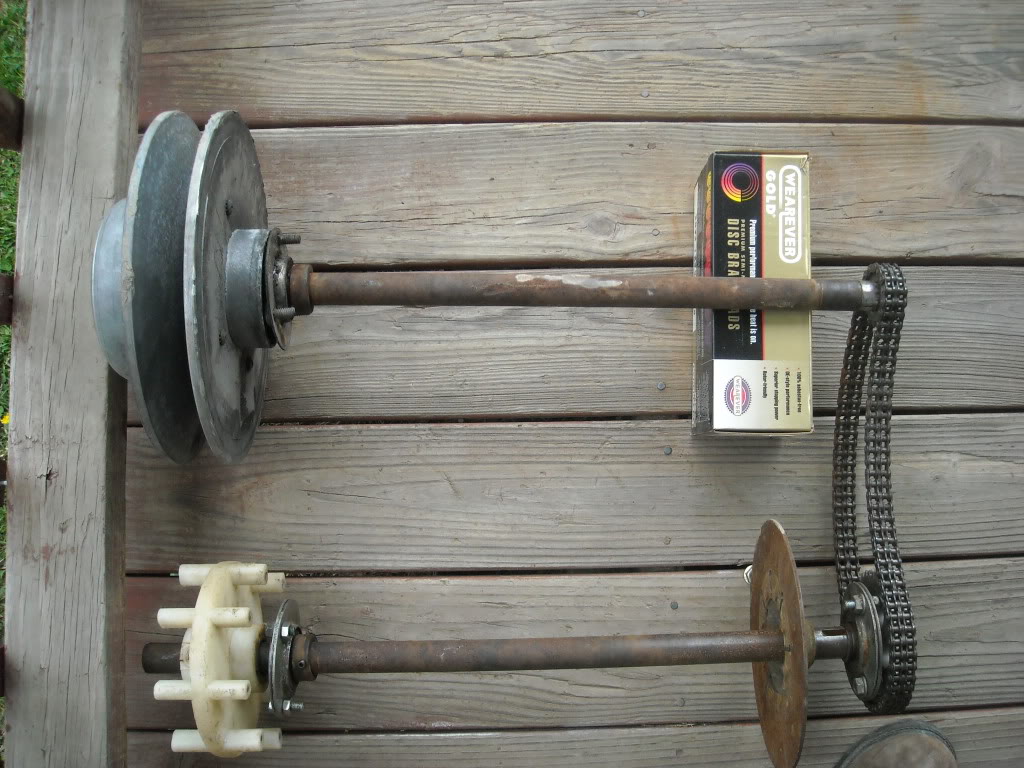

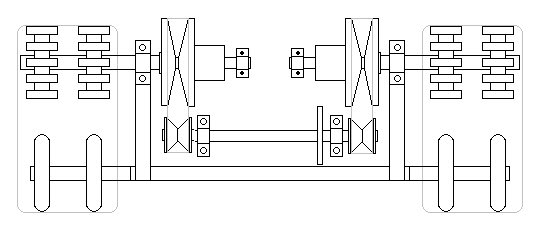

heres what i have drawn and built so far, next is the frame from 1x2" square tubing

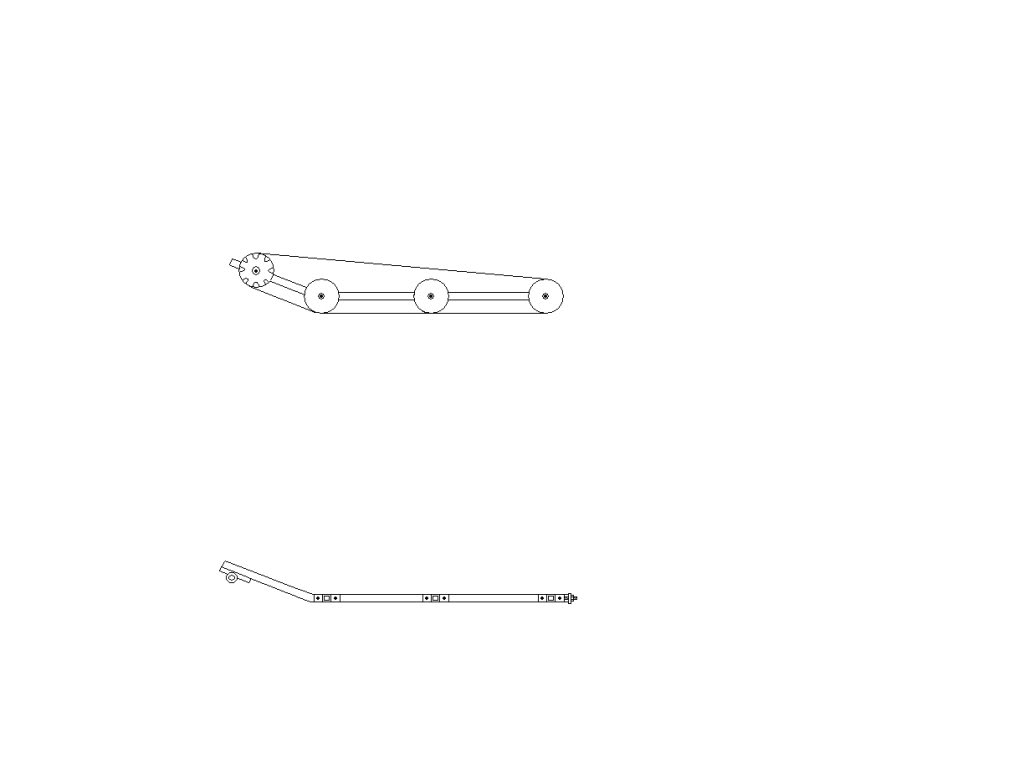

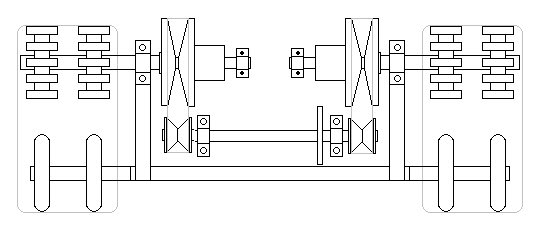

heres one u cna buy the plans from ebay

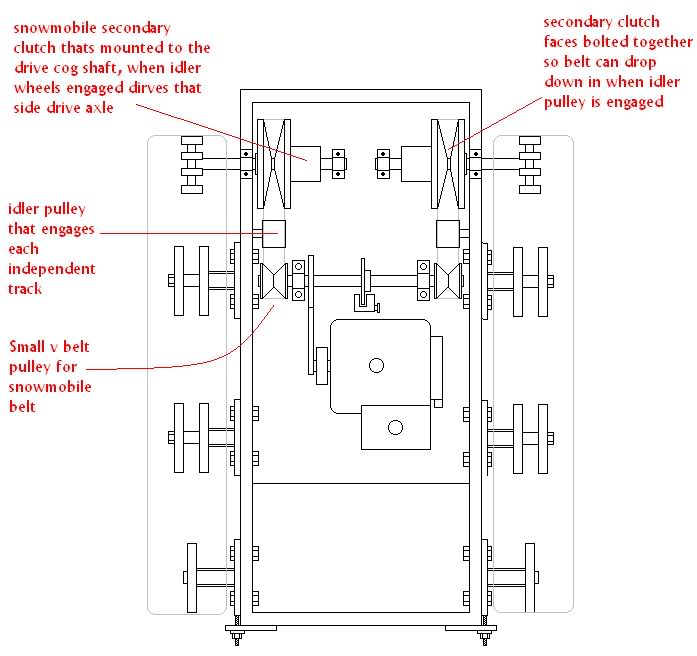

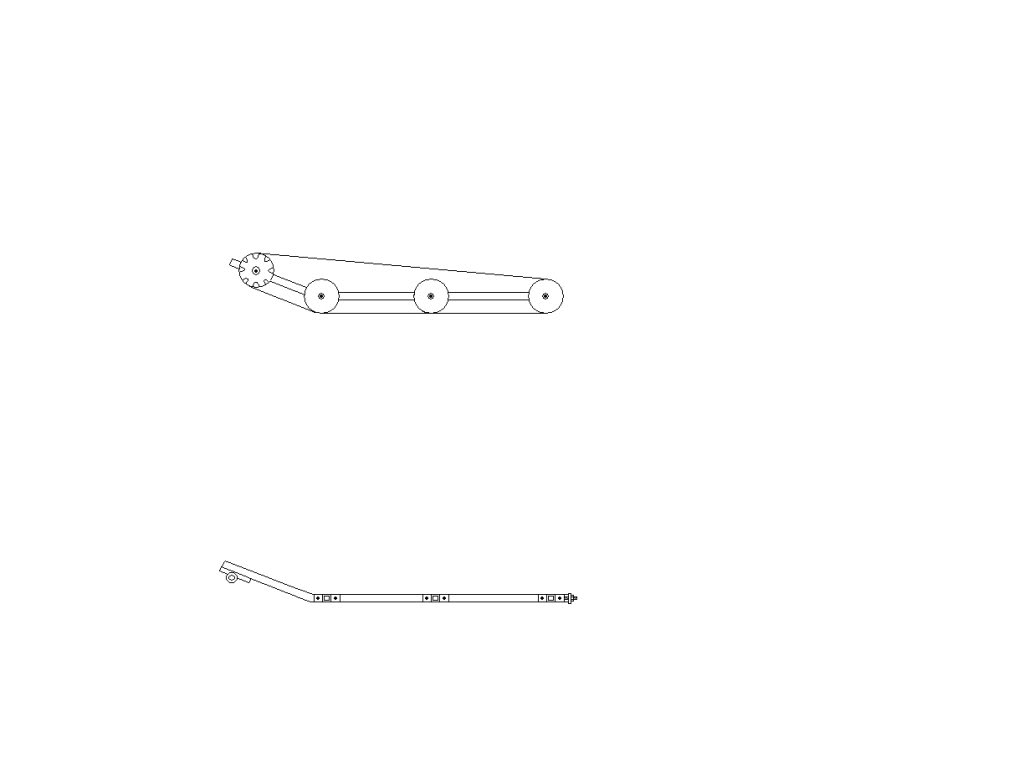

then my own plans i drew up on paint

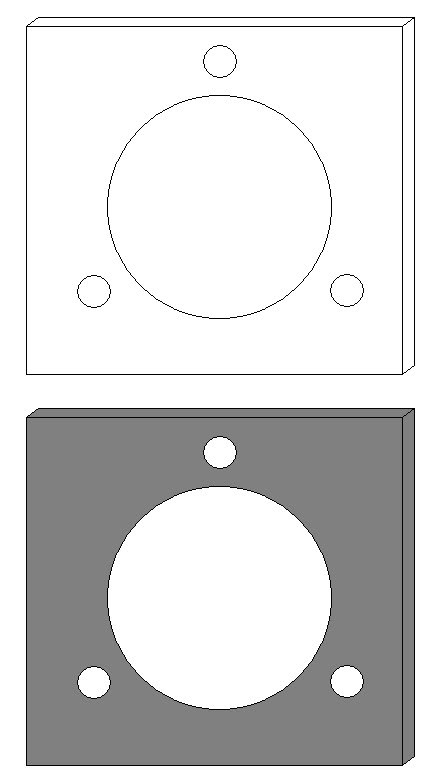

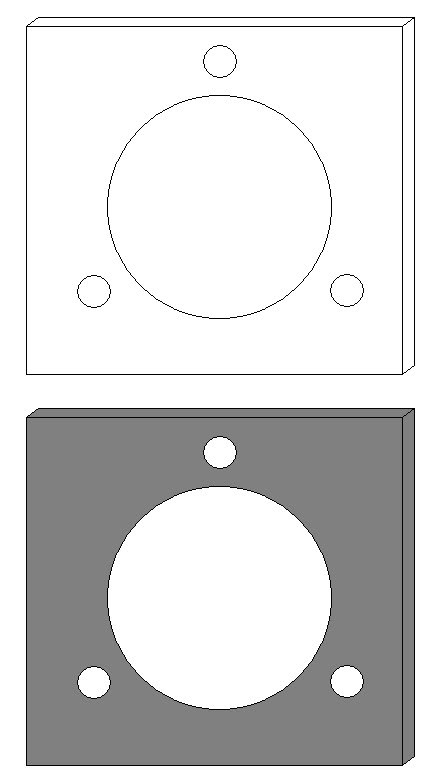

4x6 "bearing flange plates

so what ya think?

Here is a picture that i had sketched outta my head in the car one day then the other day i decided to sit down on pain and sketch it out a little neater i haven’t got went trough and priced all the drive parts with the motor, getting used tracks and idlers from a friend,and using snowmobile parts i got for free for the rest

heres what i have drawn and built so far, next is the frame from 1x2" square tubing

heres one u cna buy the plans from ebay

then my own plans i drew up on paint

4x6 "bearing flange plates

so what ya think?