So, weather was fine the other day, -5c and sunny, so my son and I went riding.

He has got the DT200 powered Blaster running fine, so I took his DT200 bike along to compare.

As well, I just had my KTM 250 powered Blaster out alongside his quad the other day and we have a lot of time on the stock Blaster motor.

The DT bike is interesting in that it has a tachometer on it so we can see what it is doing at what RPM.

I'll start with the DT200 and use it as a yardstick to compare the others.

DT200

This bike idles from 800-1200 rpm, 3000-4000 on choke. Doesn't sound that high but that is what the tach reads. All these 2 stroke engines are similar.

There is not much power under 4000 rpm even with the working powervalve. Less than the Blaster 200. It needs the low 1st gear to get rolling.

At about 4000rpm power builds quickly and it will wheelie in the first 3 gears at this rpm. 4000-6000 feels equal to Blaster 200.

At 6000-8000 rpm there is a sudden and strong burst of power. Better suited to pavement in higher gears as it just spins on dirt.

The engine will rev to 9000 rpm but power drops off after 8000. This is with a totally stock bike, no mods.

This bike will easily putter through trails at low rpm (and power) or run all day on the highway at 8000 rpm keeping up with traffic.

Feels best accelerating in the 5000-7000 range, pulls strong and ever increasing.

Blaster 200

Since most of you have one of these I hope my descriptions will sound familiar. I'll guess at the rpm.

Some mods, FMF pipe (more rpm), high flow air filter but otherwise close to stock.

Like the DT200 it sounds like it idles well at about 800 rpm. More torque on the bottom end than the DT200. Pulls away better off idle.

What seems like 2000-5000rpm is the fat part of the powerband, it grunts well here.

Getting up hills takes an 8000 rpm start at the bottom, it spins a bit but generally settles back into the 3-5000 rpm range and holds there.

If the rpm drop much below what feels like 3000rpm you will have to jump for another gear, fan the clutch, or bog out.

The Blaster likes running up and down the rpm range, but feels uncomfortable sitting at max rpm.

More at home trail riding than hill climbing or blasting down roads at max revs.

DT200 cylinder on a Blaster bottom end, no powervalve, FMF pipe:

Neil (Triplecrown) has done some fine work jetting this beast lately. He has filled in some of the mid-range and it really honks on top end.

Even so it has less power than the DT200 and Blaster under about 6000 rpm, then it comes on in a big burst.

The FMF pipe seems to give this engine more power and rpm than the stock DT200. It pulls hard from about 6000 rpm to quits (9000?).

In 3rd or 4th gear on hillclimbs it spins the tires relentlessly, not bogging down unless you let off the throttle. It screams.

But it will bog down if you let the rpm slip below about 6000 rpm. A fan of the clutch or quick downshift will usually bring it back to life.

There is enough power for trail riding in the 2000-6000 range but just barely. It likes more rpm than that in the higher gears on sand.

It has the wonderous sudden scream of an angry motorcross bike as it comes on pipe at 6000rpm. Like an angry bee.

The sudden burst of power from 6000-9000 usually breaks the rear tires loose and launches you ahead or into a light front tire wheelie.

It is a lot of fun, but demands that you be in the right gear at all times or the fun stops.

KTM 250SX in a Blaster chassis, lengthened Gnarly (torque) pipe

First gear is tall. Unlike the Blaster & DT, it is hard to start away without stalling. The clutch has to be feathered.

As soon as the clutch is fully out and you're rolling, your troubles are over. Tapping the throttle even at idle results in wheelspin or wheelie.

The tall gears do mean you are rolling along a quite a fast pace, even at idle. If you want to go slower, you have to feather the clutch.

This is a pain and often results in stalling in rough sections, so I "giv'er" 1/2 throttle through the rough stuff, fanning clutch to avoid

stalls and complete flip over wheelies. The strong acceleration tends to make you want to hunch forward resulting in a lot of wheel spin.

In fact, sometimes this bike seems disappointing because it doesn't have the wheelie tendency of say the 660 Raptor.

This is because you are hunching forward against the acceleration and the quick throttle response readily breaks the wheels free.

Lean back and it will pop up into a wheelie pretty much any time. The stock swingarm makes it pop up quick too. 3" longer arm coming.

The lengthened Gnarly pipe really works on this bike. Low rpm still has great gobs of torque and instant response.

Crack the throttle and start clicking gears as fast as you can, she will hit 65mph in 5th as quick as you can click.

Power is linear and no sign of sudden powerband, again the lengthened Gnarly in action. Hillclimbing is a dream.

No need to hit max revs or full throttle, she will go up any hill in any gear at half revs if the tires have anything to grab. Almost boring to watch.

Full throttle just brings wheelspin so you just work the throttle carefully up the hill.

For long straight stretches this bike is more comfortable at 3/4 revs and about 1/4 throttle.

Crazy power, I don't feel a need for more yet, just wishing for a wider spread gearbox.

Some (pretty lame I admit) vids of the KTM250 and stock (air cooled) Blaster from a while back:

Steve's KTM250 Blaster

Neil's 200 Blaster

Listen to the RPM differences between the bikes.

The DT200 Blaster has nearly the top end power of the KTM250, but only in a narrow band. Power valve alone will not fix this.

The DT200 bike proves this. We are going to work on this over the winter.

He has got the DT200 powered Blaster running fine, so I took his DT200 bike along to compare.

As well, I just had my KTM 250 powered Blaster out alongside his quad the other day and we have a lot of time on the stock Blaster motor.

The DT bike is interesting in that it has a tachometer on it so we can see what it is doing at what RPM.

I'll start with the DT200 and use it as a yardstick to compare the others.

DT200

This bike idles from 800-1200 rpm, 3000-4000 on choke. Doesn't sound that high but that is what the tach reads. All these 2 stroke engines are similar.

There is not much power under 4000 rpm even with the working powervalve. Less than the Blaster 200. It needs the low 1st gear to get rolling.

At about 4000rpm power builds quickly and it will wheelie in the first 3 gears at this rpm. 4000-6000 feels equal to Blaster 200.

At 6000-8000 rpm there is a sudden and strong burst of power. Better suited to pavement in higher gears as it just spins on dirt.

The engine will rev to 9000 rpm but power drops off after 8000. This is with a totally stock bike, no mods.

This bike will easily putter through trails at low rpm (and power) or run all day on the highway at 8000 rpm keeping up with traffic.

Feels best accelerating in the 5000-7000 range, pulls strong and ever increasing.

Blaster 200

Since most of you have one of these I hope my descriptions will sound familiar. I'll guess at the rpm.

Some mods, FMF pipe (more rpm), high flow air filter but otherwise close to stock.

Like the DT200 it sounds like it idles well at about 800 rpm. More torque on the bottom end than the DT200. Pulls away better off idle.

What seems like 2000-5000rpm is the fat part of the powerband, it grunts well here.

Getting up hills takes an 8000 rpm start at the bottom, it spins a bit but generally settles back into the 3-5000 rpm range and holds there.

If the rpm drop much below what feels like 3000rpm you will have to jump for another gear, fan the clutch, or bog out.

The Blaster likes running up and down the rpm range, but feels uncomfortable sitting at max rpm.

More at home trail riding than hill climbing or blasting down roads at max revs.

DT200 cylinder on a Blaster bottom end, no powervalve, FMF pipe:

Neil (Triplecrown) has done some fine work jetting this beast lately. He has filled in some of the mid-range and it really honks on top end.

Even so it has less power than the DT200 and Blaster under about 6000 rpm, then it comes on in a big burst.

The FMF pipe seems to give this engine more power and rpm than the stock DT200. It pulls hard from about 6000 rpm to quits (9000?).

In 3rd or 4th gear on hillclimbs it spins the tires relentlessly, not bogging down unless you let off the throttle. It screams.

But it will bog down if you let the rpm slip below about 6000 rpm. A fan of the clutch or quick downshift will usually bring it back to life.

There is enough power for trail riding in the 2000-6000 range but just barely. It likes more rpm than that in the higher gears on sand.

It has the wonderous sudden scream of an angry motorcross bike as it comes on pipe at 6000rpm. Like an angry bee.

The sudden burst of power from 6000-9000 usually breaks the rear tires loose and launches you ahead or into a light front tire wheelie.

It is a lot of fun, but demands that you be in the right gear at all times or the fun stops.

KTM 250SX in a Blaster chassis, lengthened Gnarly (torque) pipe

First gear is tall. Unlike the Blaster & DT, it is hard to start away without stalling. The clutch has to be feathered.

As soon as the clutch is fully out and you're rolling, your troubles are over. Tapping the throttle even at idle results in wheelspin or wheelie.

The tall gears do mean you are rolling along a quite a fast pace, even at idle. If you want to go slower, you have to feather the clutch.

This is a pain and often results in stalling in rough sections, so I "giv'er" 1/2 throttle through the rough stuff, fanning clutch to avoid

stalls and complete flip over wheelies. The strong acceleration tends to make you want to hunch forward resulting in a lot of wheel spin.

In fact, sometimes this bike seems disappointing because it doesn't have the wheelie tendency of say the 660 Raptor.

This is because you are hunching forward against the acceleration and the quick throttle response readily breaks the wheels free.

Lean back and it will pop up into a wheelie pretty much any time. The stock swingarm makes it pop up quick too. 3" longer arm coming.

The lengthened Gnarly pipe really works on this bike. Low rpm still has great gobs of torque and instant response.

Crack the throttle and start clicking gears as fast as you can, she will hit 65mph in 5th as quick as you can click.

Power is linear and no sign of sudden powerband, again the lengthened Gnarly in action. Hillclimbing is a dream.

No need to hit max revs or full throttle, she will go up any hill in any gear at half revs if the tires have anything to grab. Almost boring to watch.

Full throttle just brings wheelspin so you just work the throttle carefully up the hill.

For long straight stretches this bike is more comfortable at 3/4 revs and about 1/4 throttle.

Crazy power, I don't feel a need for more yet, just wishing for a wider spread gearbox.

Some (pretty lame I admit) vids of the KTM250 and stock (air cooled) Blaster from a while back:

Steve's KTM250 Blaster

Neil's 200 Blaster

Listen to the RPM differences between the bikes.

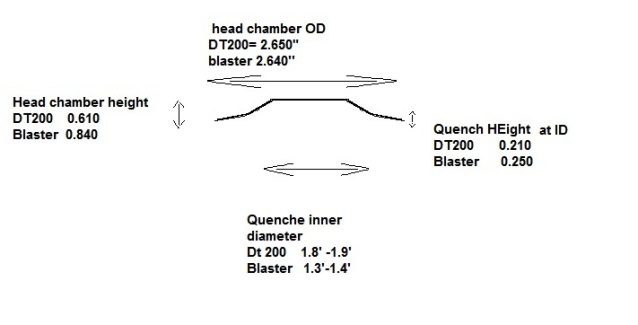

The DT200 Blaster has nearly the top end power of the KTM250, but only in a narrow band. Power valve alone will not fix this.

The DT200 bike proves this. We are going to work on this over the winter.