How would you do it?

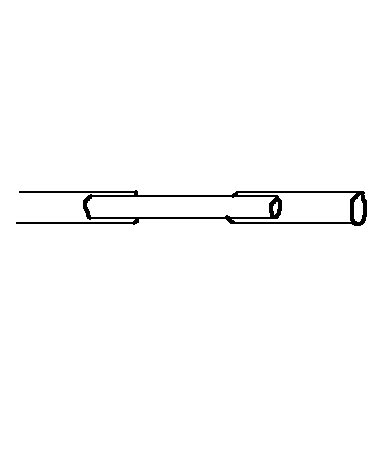

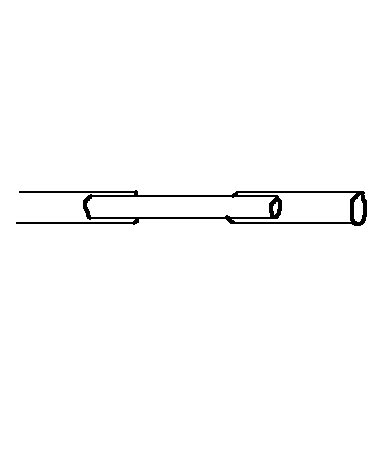

I know there are ways while still retaining strength. I was thinking cut them right in the middle. Find some solid round stock the same size as the inside diameter of the tubing. say if I want 2 inches per arm. I would cut the stock to 4 inches or so slide it out and weld the crap out of it. Or maybe if I wanted 2 inches cut the stock to 8 inches. This way I could have more around 3 inches of overlap. The only downside to this would probably be some added weight. Not more than a few pounds. The stock arms are thin and I think this would be stronger than before? Without completely redoing the whole tubes with a bender or spending $200. Give your thoughts because I plan on doing something like this soon.

I know there are ways while still retaining strength. I was thinking cut them right in the middle. Find some solid round stock the same size as the inside diameter of the tubing. say if I want 2 inches per arm. I would cut the stock to 4 inches or so slide it out and weld the crap out of it. Or maybe if I wanted 2 inches cut the stock to 8 inches. This way I could have more around 3 inches of overlap. The only downside to this would probably be some added weight. Not more than a few pounds. The stock arms are thin and I think this would be stronger than before? Without completely redoing the whole tubes with a bender or spending $200. Give your thoughts because I plan on doing something like this soon.