porting tools

- Thread starter sicivicdude

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

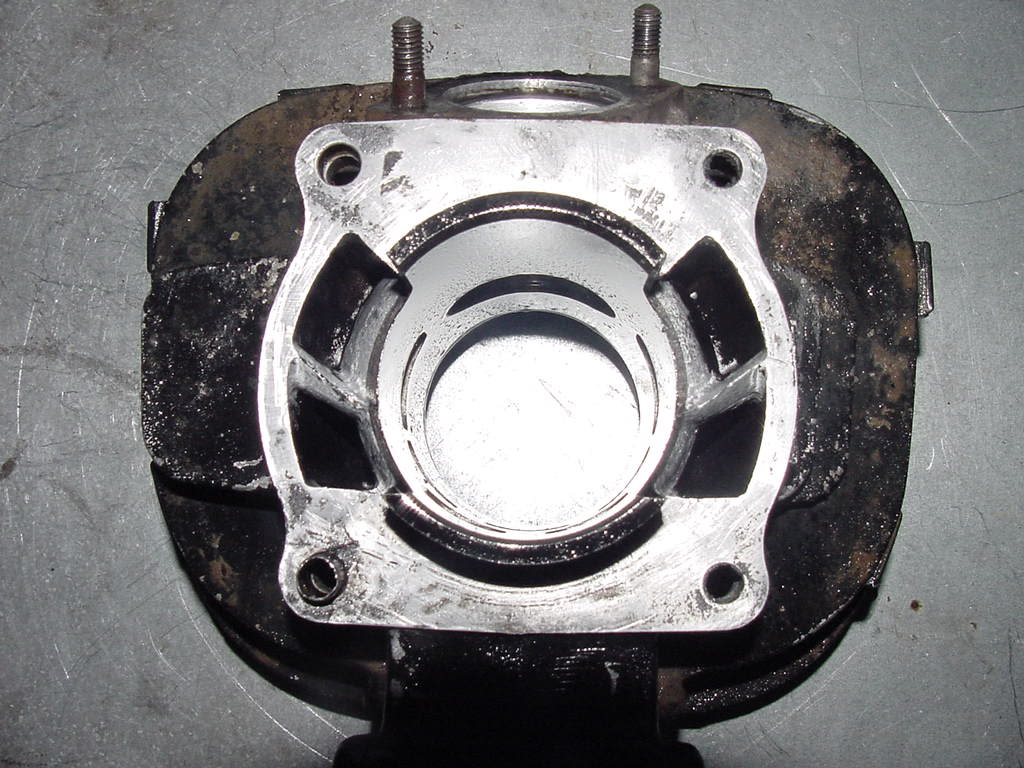

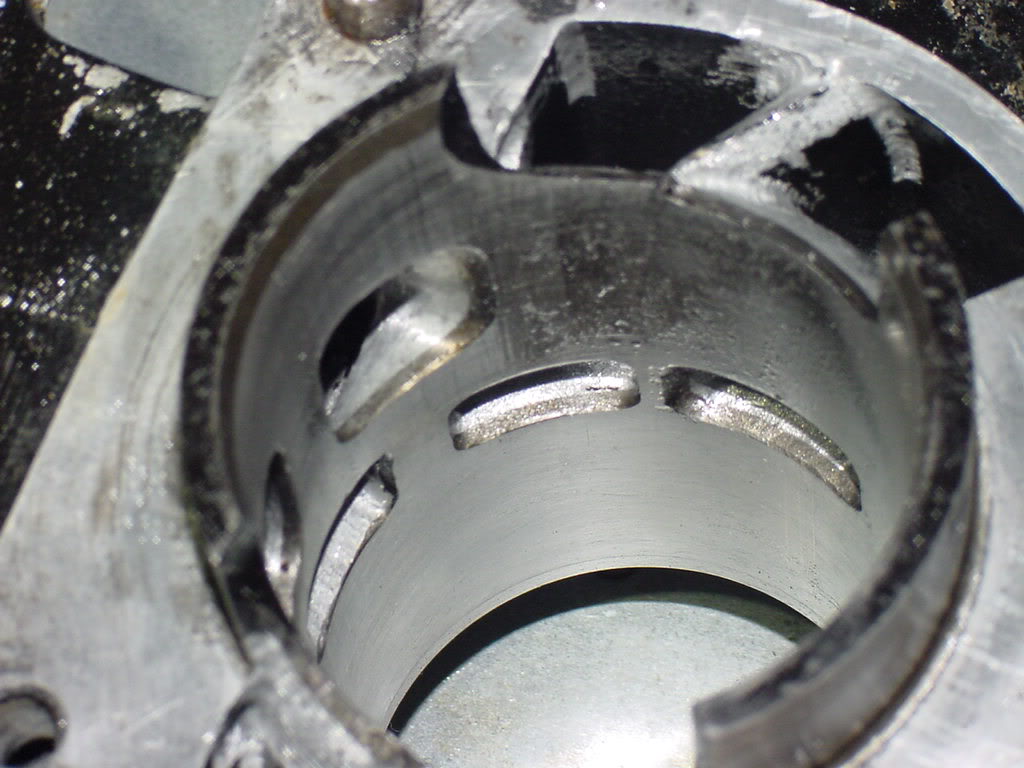

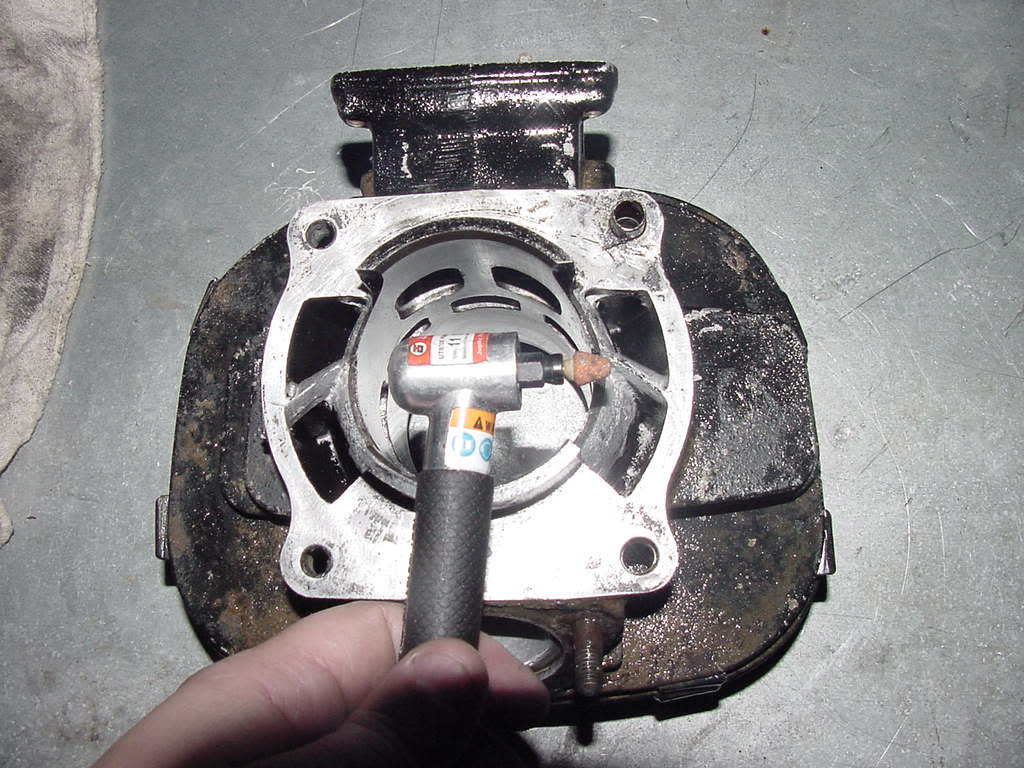

MAN that camera takes some clear shots. You can even see the swirls of WD-40 in the bore... I wiped it with oil after I used the water hose to flush the chips.

Looks great. Next time your in goldsboro let me know and i will give you some real nice carbide burs and some awsome sanding stones for free. I got some high dollar carbide stuff that you can try for nothing.

Surf, I already offered remember? You turned it down like a $2 hand job...

mmajay, it'll be a while but I'll take ya up on that one. I ordered a couple of small assorted sets of carbide but they're cheap ones. I'm sure not as good as the supplies you've got

mmajay, it'll be a while but I'll take ya up on that one. I ordered a couple of small assorted sets of carbide but they're cheap ones. I'm sure not as good as the supplies you've got

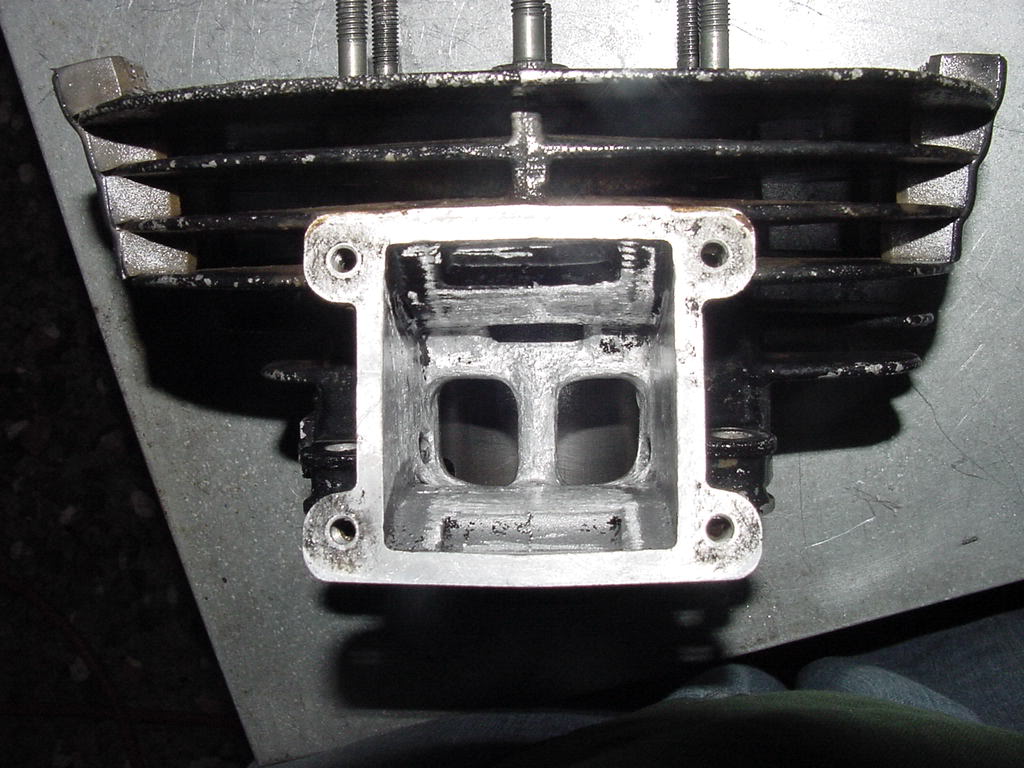

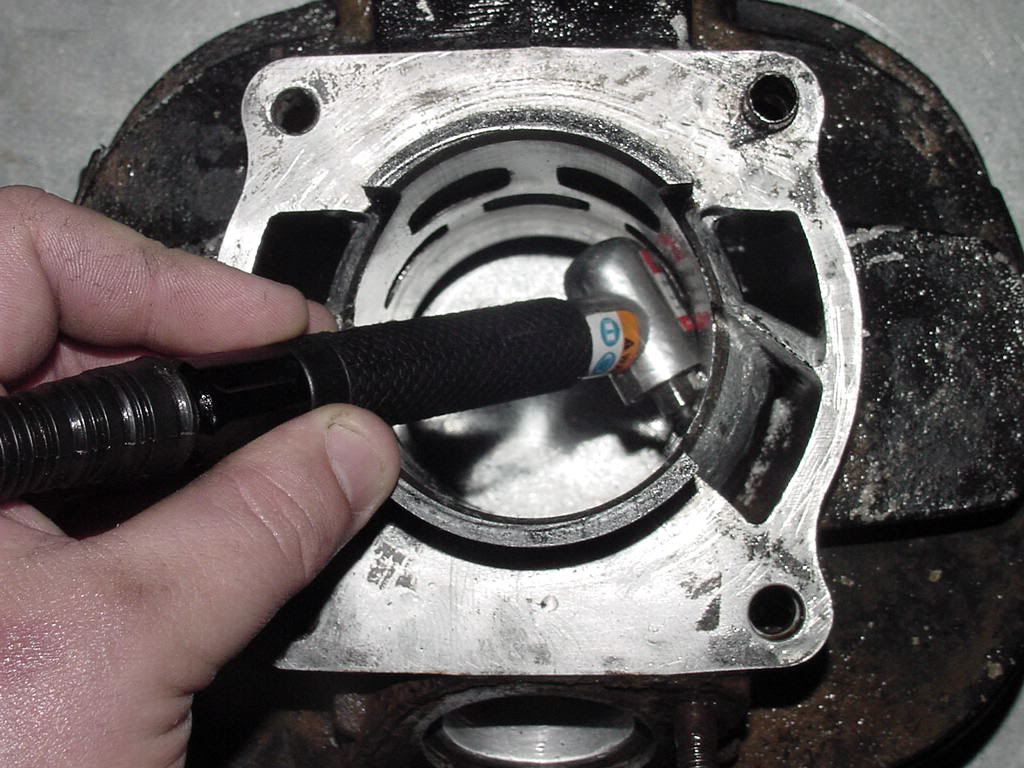

There are a few spots in the transfers which I didn't chase because I didn't alter the transfer port timing significantly. I did get the roof of the primary transfers angled up at about 5 degrees and matched the aluminum to the steel but the secondary transfers are nearly completely flat so I didn't chase the little spots.

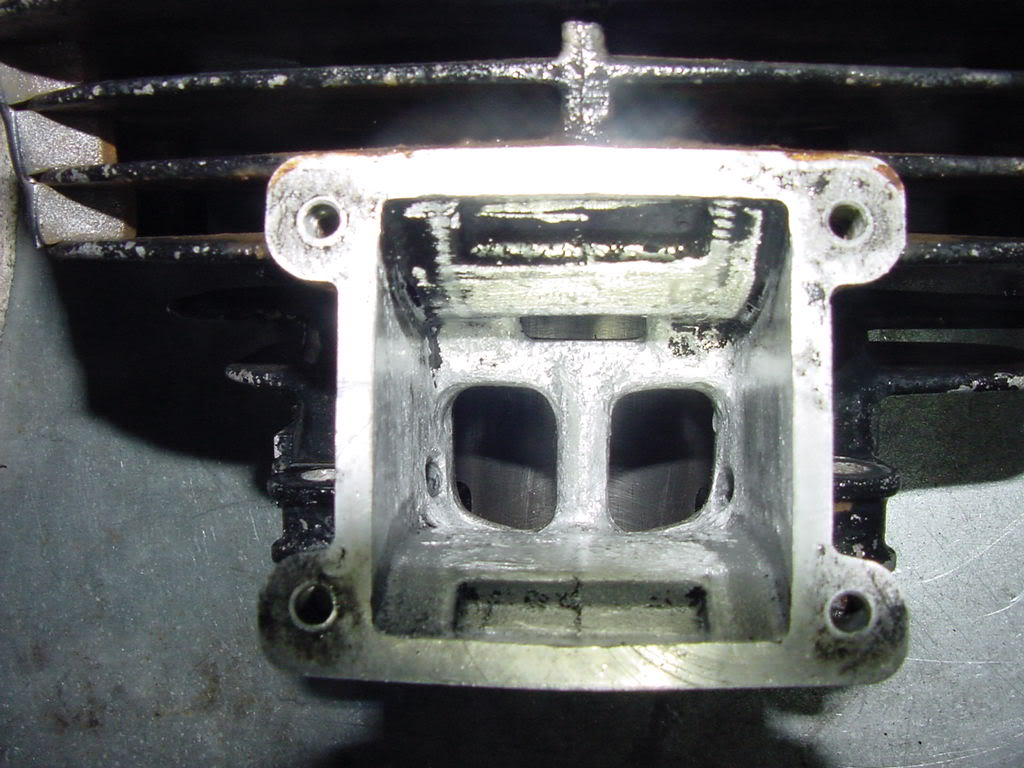

I didn't get a good picture of the exhaust port yet because I haven't put the exhaust adapter back on yet. There are a few "scratches" in the exhaust port sanding didn't take out because I was using (ironically after mmajay's comment) a pretty well worked over burr and it was digging in some areas and skipping in others. It dug a few little spots that sanding didn't get down to but it should affect nothing at all.

I raised the intake windows roofs 1mm and narrowed the bridge about 1mm.

I raised the exhaust port 2mm and widened it about 2mm specifically towards the upper corners. I will be taking the degree wheel over when the top end gets installed on twostroker99's engine to see what the timing yields on the bottom end it will be mated to. I will report back the timing figures when I have them for that engine.

I didn't get a good picture of the exhaust port yet because I haven't put the exhaust adapter back on yet. There are a few "scratches" in the exhaust port sanding didn't take out because I was using (ironically after mmajay's comment) a pretty well worked over burr and it was digging in some areas and skipping in others. It dug a few little spots that sanding didn't get down to but it should affect nothing at all.

I raised the intake windows roofs 1mm and narrowed the bridge about 1mm.

I raised the exhaust port 2mm and widened it about 2mm specifically towards the upper corners. I will be taking the degree wheel over when the top end gets installed on twostroker99's engine to see what the timing yields on the bottom end it will be mated to. I will report back the timing figures when I have them for that engine.

Last edited:

WOW!!!!!That tool is perfect for what I needed on the transfers!!!!!!!! I cant wait to buy one.what port timing did you end up with on this one? I use 1/4 inch long carbide cutters and a drill when im hoggin out the big stuff.

I'm going to order 1/4" head HSS single cut burrs to fit in the 1/8" collet of the straight die grinder. Hopefully that'll give me "hogging" capacity because I sure don't have it now...

I didn't modify it a lot off stock port timing (per the er...customer's request), I just raised the exhaust port slightly and cleaned up everything. I'm going to check and record the port timing when we put the cylinder back down on twostroker99's bottom end. I'll report exactly what I've got then.

I didn't modify it a lot off stock port timing (per the er...customer's request), I just raised the exhaust port slightly and cleaned up everything. I'm going to check and record the port timing when we put the cylinder back down on twostroker99's bottom end. I'll report exactly what I've got then.

I:I When you get a chance could you either put linc or web addy for Global? I only clicked first site to come up and it didn't have any air tools. First port job I did was with a drill , die files, and emery cloth  . If Dremels were avaiable back then I wasn't aware of them . That was so long ago that Jennings book was hot off the presses

. If Dremels were avaiable back then I wasn't aware of them . That was so long ago that Jennings book was hot off the presses

You can either go to http://www.globalindustrial.com/ and search pencil die grinder (it'll show the straight for $110 and the angled for $133 or you can search for this stock number: WBB231423

Either way should turn up the least expensive new angled air pencil die grinder I could find (even from the importer, florida pneumatics)

Either way should turn up the least expensive new angled air pencil die grinder I could find (even from the importer, florida pneumatics)

Alright, so I have hit my first hickup.... I broke my right angle pencil grinder!

Well not exactly the grinder itself, the collet. If you read the fine print in the manual, the part diagram has two different collets listed. Because of their design, you cannot use the same collet to clamp down on an 1/8" shank and a 3mm shank. They make two different ones... and now I know that.

I bought an assorted pack of carbide burrs and was working on a practice cylinder and couldn't quite get the shank tight inside the collet and couldn't figure out why. I'll be calling florida pneumatic in the morning to order a replacement 1/8" collet and a 3mm collet. I have a feeling that the 3mm collet would do both but the 1/8" won't do the 3mm shanks.

I'll let you know when I talk to a live human being tomorrow how expensive this little problem is and if the 3mm collet will in fact do both the 3mm and 1/8" shanks.

Well not exactly the grinder itself, the collet. If you read the fine print in the manual, the part diagram has two different collets listed. Because of their design, you cannot use the same collet to clamp down on an 1/8" shank and a 3mm shank. They make two different ones... and now I know that.

I bought an assorted pack of carbide burrs and was working on a practice cylinder and couldn't quite get the shank tight inside the collet and couldn't figure out why. I'll be calling florida pneumatic in the morning to order a replacement 1/8" collet and a 3mm collet. I have a feeling that the 3mm collet would do both but the 1/8" won't do the 3mm shanks.

I'll let you know when I talk to a live human being tomorrow how expensive this little problem is and if the 3mm collet will in fact do both the 3mm and 1/8" shanks.

I was going to say, now we get to find out how the manufacturer handles selling spare parts!

I broke it before I knew what was happening... the threads just ripped apart when I threw the guns on it...

I think I'm going to get both sizes replacement (if I can) and keep them together and use the correct one. I will report back, however, whether the 3mm collet will work with both 1/8" and 3mm tooling.

I broke it before I knew what was happening... the threads just ripped apart when I threw the guns on it...

I think I'm going to get both sizes replacement (if I can) and keep them together and use the correct one. I will report back, however, whether the 3mm collet will work with both 1/8" and 3mm tooling.

Alright so time for some porting figures!

I shot these off the hip (for the porting) but recorded them when we put the engine together. Here they are;

The exhaust port opens 87° ATDC for a total duration of 186°.

The primary, secondary, and boost port transfers open simultaneously at 117° ATDC for a duration of 126°.

Blow down is 30 degrees (which I hear is a little less than optimal but should be a small bump in power without going crazy)

I shot these off the hip (for the porting) but recorded them when we put the engine together. Here they are;

The exhaust port opens 87° ATDC for a total duration of 186°.

The primary, secondary, and boost port transfers open simultaneously at 117° ATDC for a duration of 126°.

Blow down is 30 degrees (which I hear is a little less than optimal but should be a small bump in power without going crazy)

Well, I hope someone looking at this knows someone who works at florida pneumatic....

While the tool may save you money... it will also cost you money. The difference is still less than the alternative but be warned, it's pricy to repair.

First off, universal tool advertises this as a 1/8 and 3mm die grinder. In it's as shipped form it is not. The difference between 3mm and 1/8" is about .007". For a normal collet, completely interchangable. For this collet... not so much.

It's kind of crappy actually... they ship it with the 1/8" collet but not the 3mm collet. I'm sure for $450 dotco ships both... but that's an arguement for another discussion. They really should include both or at least warn you that they're not interchangable.... Big bold letters in the operators manual telling you that if you have 3mm tooling, you need to call them and order the other collet because, unlike every other die grinder in the world, they're different.

I called florida pneumatic this morning. The lady on the phone was nice enough and knew just what I was talking about and looked it up straight away. She said, I have that part in stock and can ship today, it retails for $14.30. I thought the price was maybe a little bit high, if you ask me, for a small metric countersunk head screw with a hole down the middle and a slice down one side but still doable. Then she asked me for my account number and I told her I didn't have an account number... she told me I would have to call a distributor to order the part and gave me the number for MSC.

Well...... MSC didn't have the 3mm part listed in their system at all. Luckily I got the one lady on the phone who is proactive and she went ahead and called florida pneumatic to get the part number. She came back on the phone and gave me the new MSC number and told me their price on the part... $26.70. I told her I would call her back.

Now $15 for a metric screw (basically what it is) is a little high but doable. I understand they have to pay some 10 year old asian kid $.18 an hour to make those things, fly them halfway across the globe, and still make enough money to feed the folks in florida... and I understand distributors have a 40% - 50% markup on things they sell so they can afford to eat too, but almost $30 for a metric screw?!?!? I mean I wanted a screw but not that way.

I just can't see paying $27 plus shipping for something I can make myself.... hey, wait a minute.... so that started the wheels turning.

What if I could take a metric countersunk head screw, drill the center the correct size, grind it to 6mm wide at the top (so the wrench still works), and then put a slice down one side?

If this were a business, it would not prove efficient for me to take the time to work all this out but this isn't a business... it's just little old me at house working on junk. I think I can make a new collet by hand and I think I'm going to do just that.

While the tool may save you money... it will also cost you money. The difference is still less than the alternative but be warned, it's pricy to repair.

First off, universal tool advertises this as a 1/8 and 3mm die grinder. In it's as shipped form it is not. The difference between 3mm and 1/8" is about .007". For a normal collet, completely interchangable. For this collet... not so much.

It's kind of crappy actually... they ship it with the 1/8" collet but not the 3mm collet. I'm sure for $450 dotco ships both... but that's an arguement for another discussion. They really should include both or at least warn you that they're not interchangable.... Big bold letters in the operators manual telling you that if you have 3mm tooling, you need to call them and order the other collet because, unlike every other die grinder in the world, they're different.

I called florida pneumatic this morning. The lady on the phone was nice enough and knew just what I was talking about and looked it up straight away. She said, I have that part in stock and can ship today, it retails for $14.30. I thought the price was maybe a little bit high, if you ask me, for a small metric countersunk head screw with a hole down the middle and a slice down one side but still doable. Then she asked me for my account number and I told her I didn't have an account number... she told me I would have to call a distributor to order the part and gave me the number for MSC.

Well...... MSC didn't have the 3mm part listed in their system at all. Luckily I got the one lady on the phone who is proactive and she went ahead and called florida pneumatic to get the part number. She came back on the phone and gave me the new MSC number and told me their price on the part... $26.70. I told her I would call her back.

Now $15 for a metric screw (basically what it is) is a little high but doable. I understand they have to pay some 10 year old asian kid $.18 an hour to make those things, fly them halfway across the globe, and still make enough money to feed the folks in florida... and I understand distributors have a 40% - 50% markup on things they sell so they can afford to eat too, but almost $30 for a metric screw?!?!? I mean I wanted a screw but not that way.

I just can't see paying $27 plus shipping for something I can make myself.... hey, wait a minute.... so that started the wheels turning.

What if I could take a metric countersunk head screw, drill the center the correct size, grind it to 6mm wide at the top (so the wrench still works), and then put a slice down one side?

If this were a business, it would not prove efficient for me to take the time to work all this out but this isn't a business... it's just little old me at house working on junk. I think I can make a new collet by hand and I think I'm going to do just that.

I got a number 32 drill from a numbered drill set (it's .002" smaller than 3mm) and I'm going to go looking for a screw with a flat countersink headed screw with the proper threads this afternoon

Ace hardware, here we come!

I'm going to buy a handful of the screws so I have a few mistakes....er.... I mean extras on hand. If anyone else plans on possibly getting a right angle die grinder, speak up and I'll make an extra collet or two.

Ace hardware, here we come!

I'm going to buy a handful of the screws so I have a few mistakes....er.... I mean extras on hand. If anyone else plans on possibly getting a right angle die grinder, speak up and I'll make an extra collet or two.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 98

- Replies

- 2

- Views

- 133