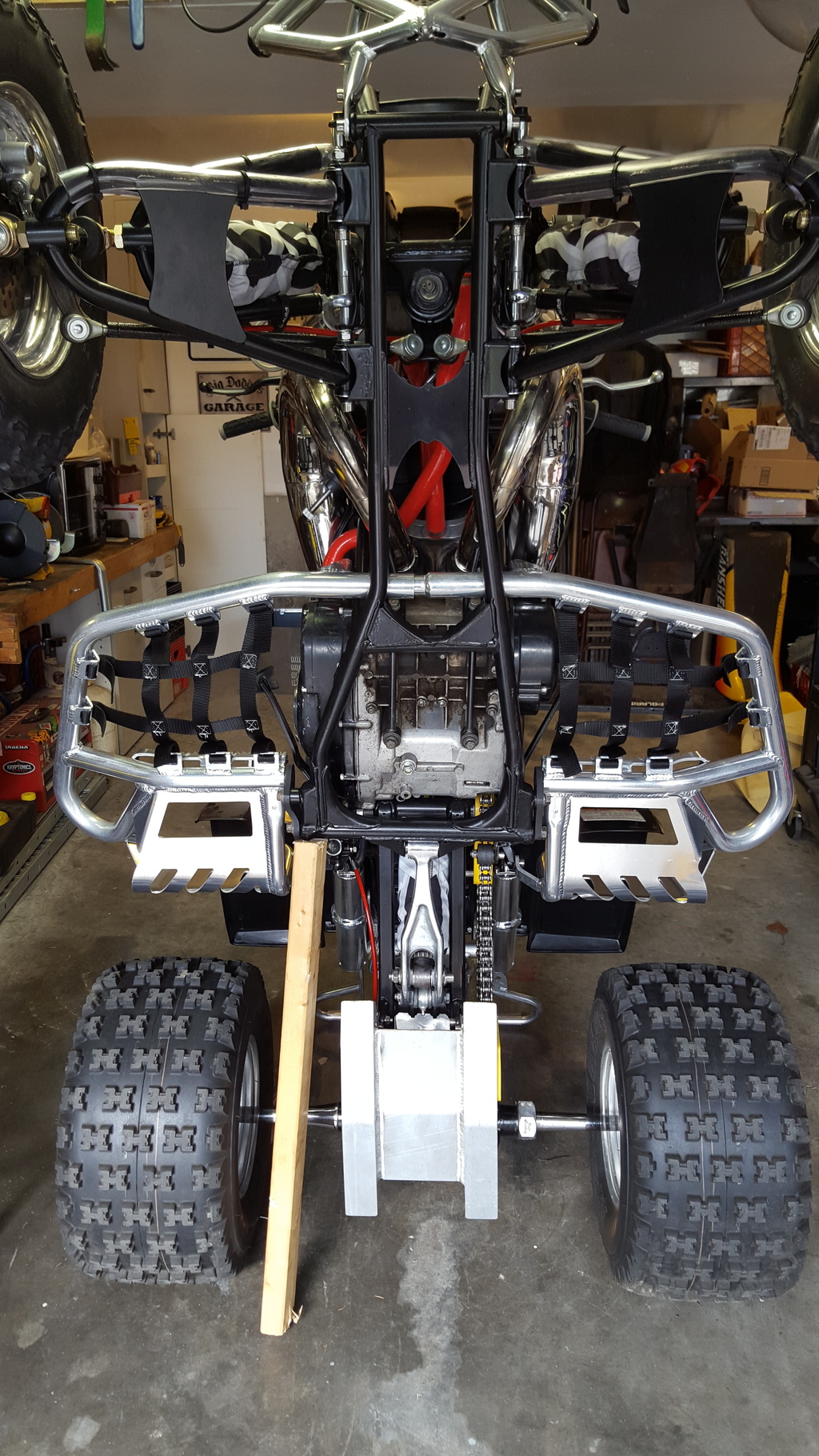

Ok So I bought a top of the line ($130) plastic skid plate. The fit and mounting design were terrible. So after looking into the cost of materials I decided I could do better and just as nice looking for less;

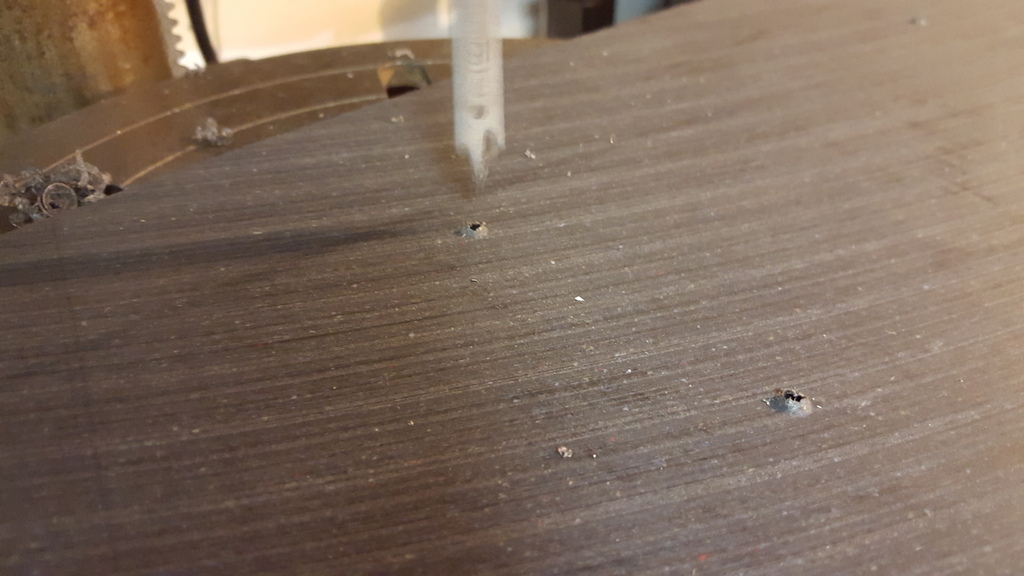

1/4" x 24" x 48" Black UHMW off Amazon - $75 shipped (prime)

2 - 10pks of 1" Plastic coated loop straps off of McMaster - $14 shipped

8 low profile M8-1.25 x 20mm bolts from an old set of front rotors - free

Satisfaction of a reliable skid plate that won't fall off on the trails - priceless

(EDIT) I ended up covering the entire bottom of the quad; Belly, shock linkage, swinger, and (coming soon) A-arms with the one sheet. NOBODY makes a set (alum or plastic) to do all of that!

1/4" x 24" x 48" Black UHMW off Amazon - $75 shipped (prime)

2 - 10pks of 1" Plastic coated loop straps off of McMaster - $14 shipped

8 low profile M8-1.25 x 20mm bolts from an old set of front rotors - free

Satisfaction of a reliable skid plate that won't fall off on the trails - priceless

(EDIT) I ended up covering the entire bottom of the quad; Belly, shock linkage, swinger, and (coming soon) A-arms with the one sheet. NOBODY makes a set (alum or plastic) to do all of that!

Last edited: