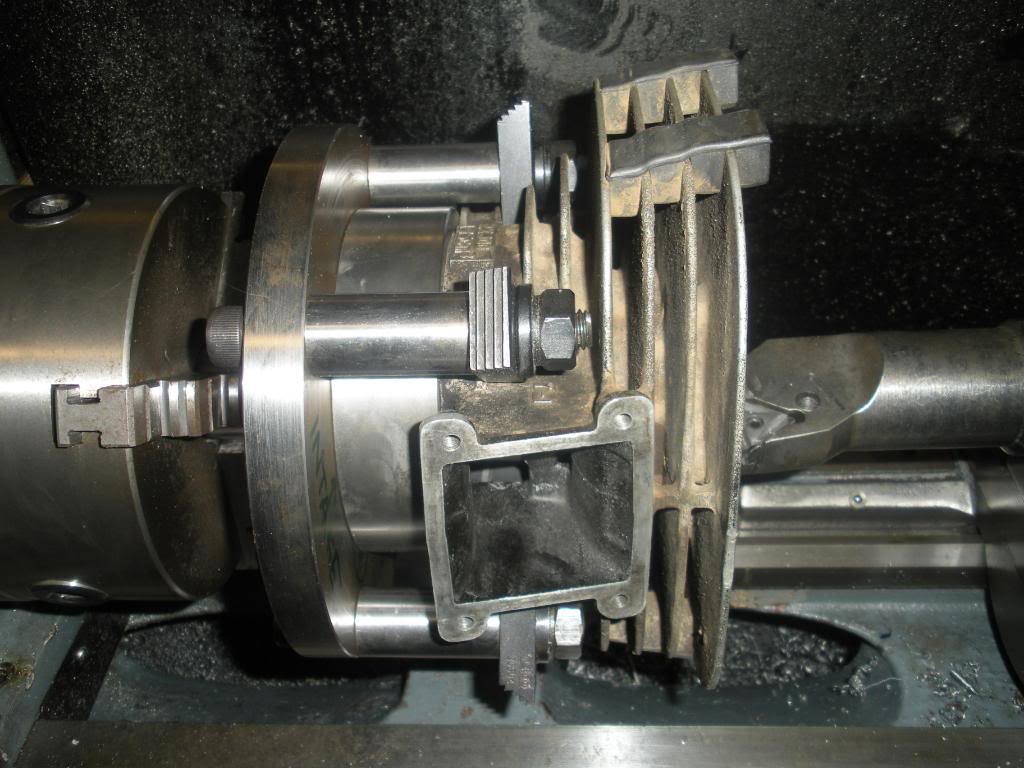

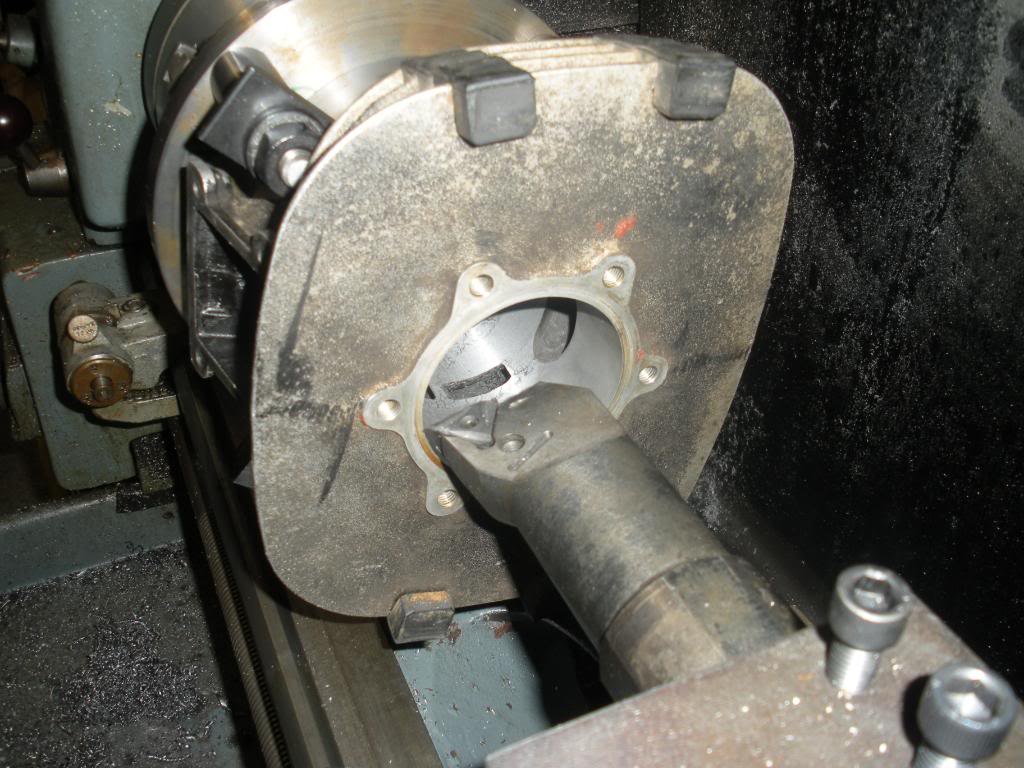

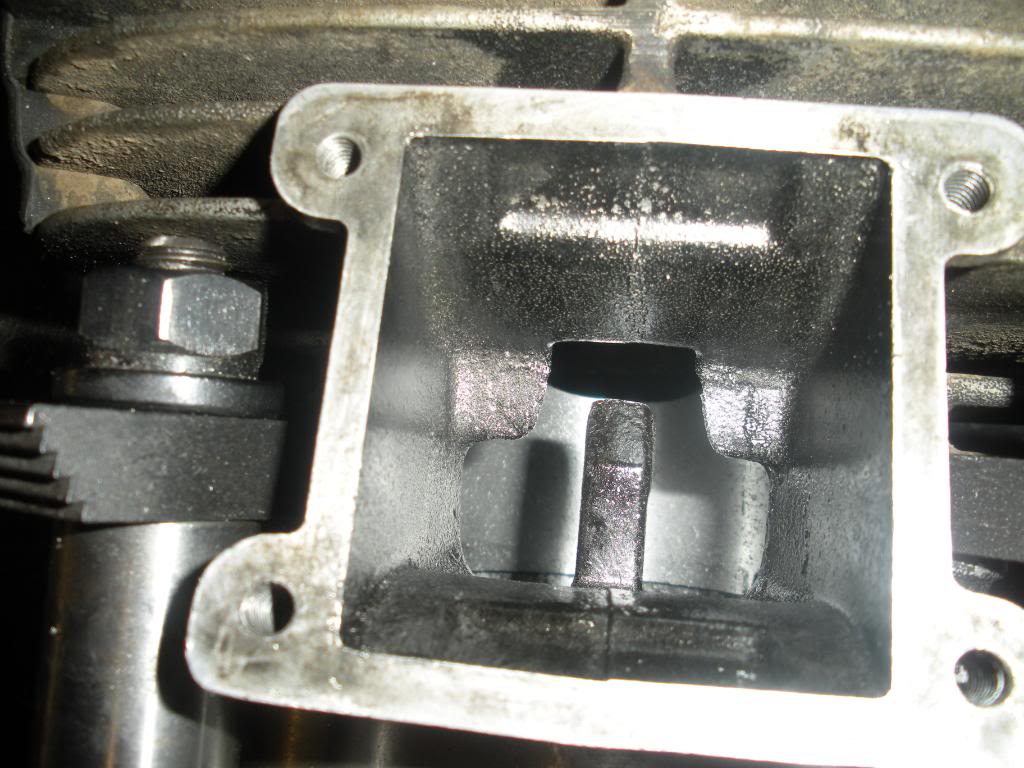

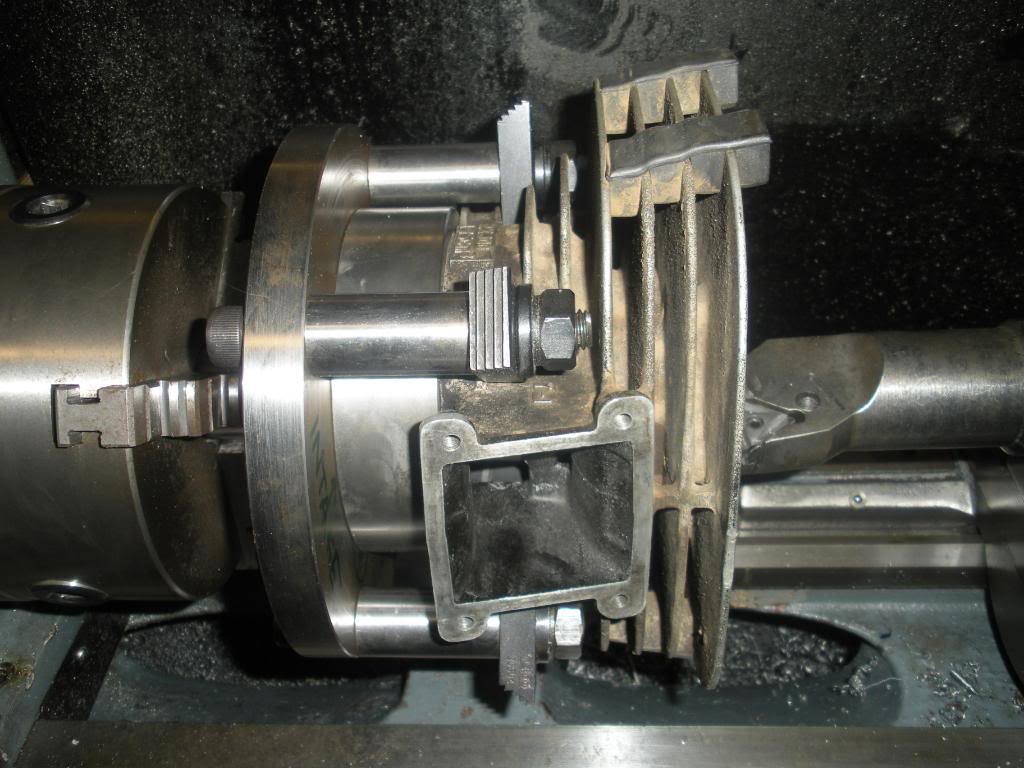

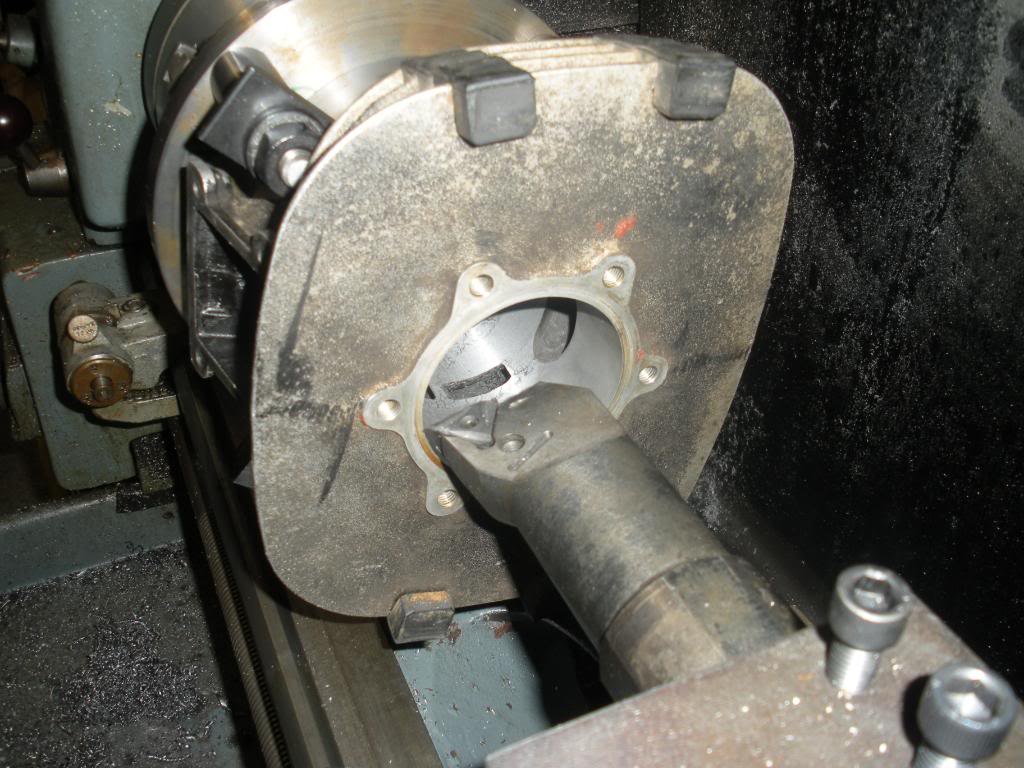

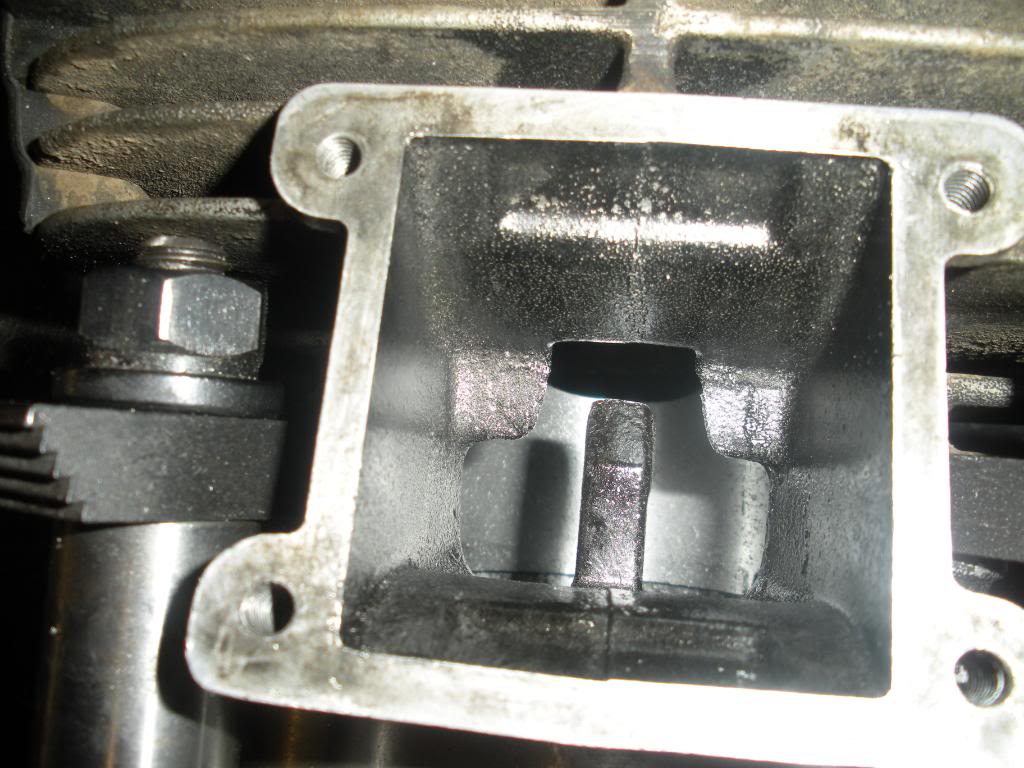

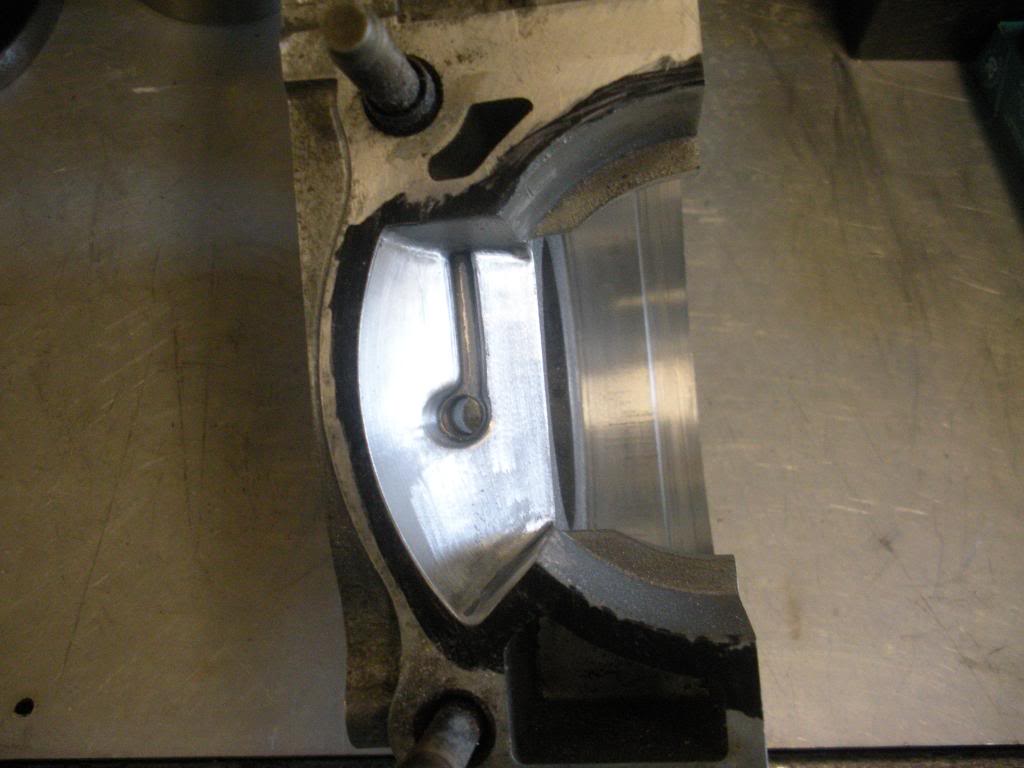

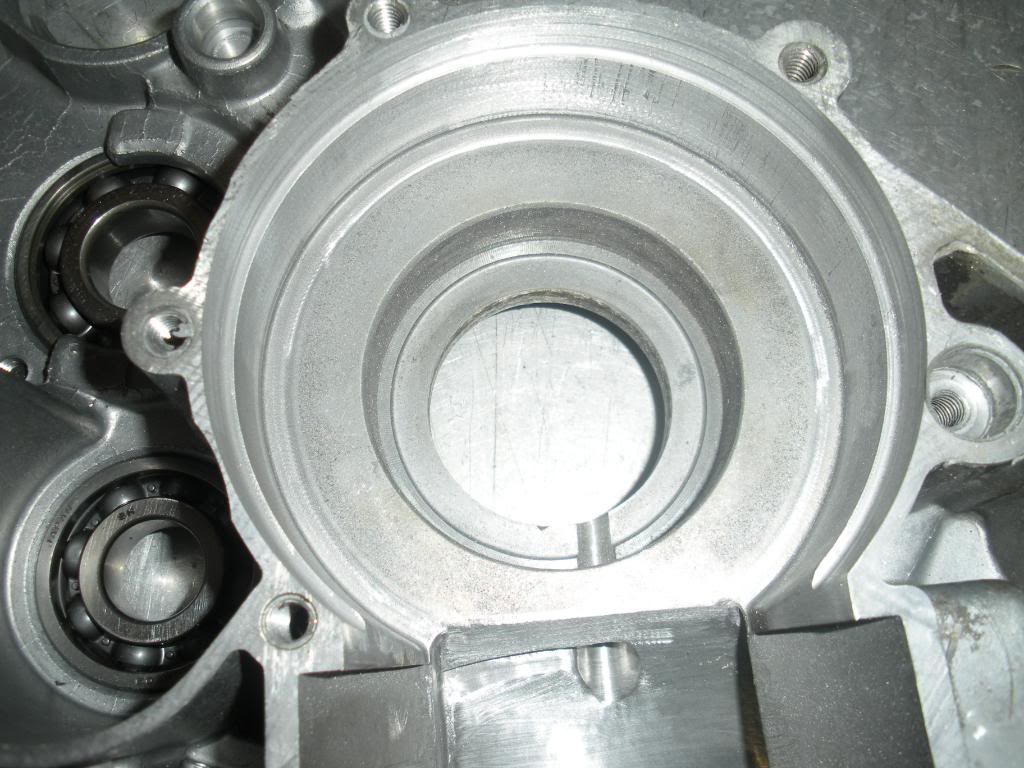

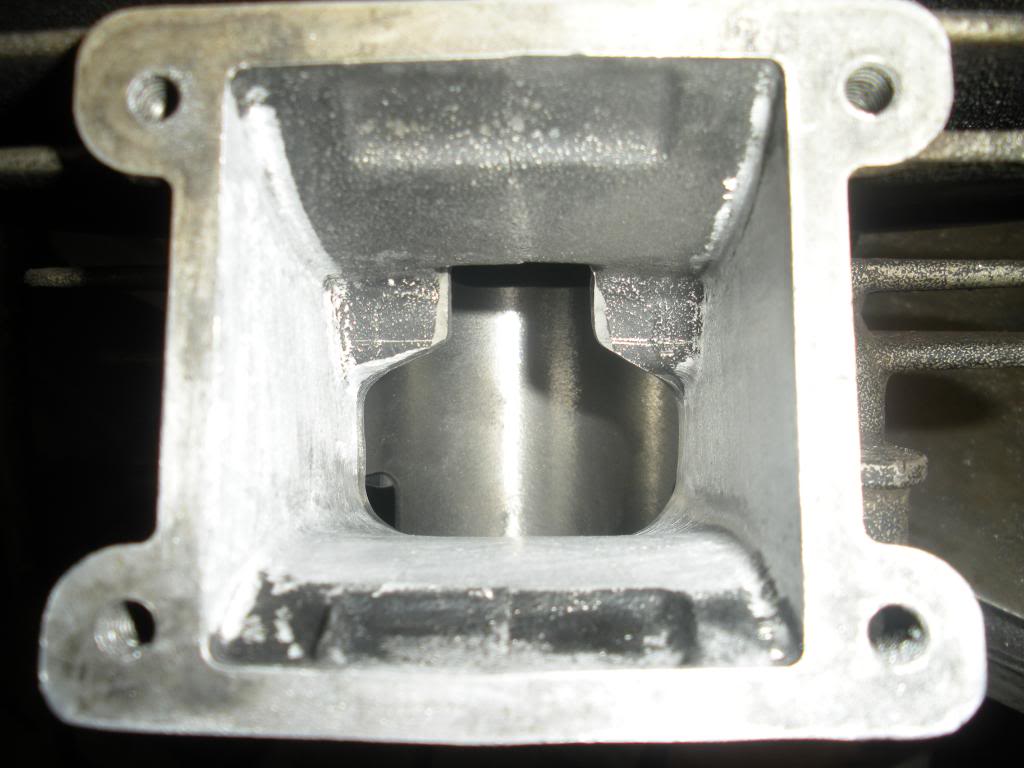

I decided to build another engine for the Bud-Light Blaster. This will be the third one this year. It's a 4mm stroker ( thanks for the crank Slick!) with an LA Sleeve 240 cylinder. The cases are trenched and match ported and I'm in the process of doing the cylinder. I'll post more pics as I take them. Here's the cylinder work I did last night for the sleeve install. Doing this on the lathe is really fast. I was able to take .125” cuts. Try that on conventional boring equipment. Check out the intake bridge after the boring for the sleeve is done. I've got to run some numbers but I think I can get away with cutting it out if I don't make the port wider.