spark knocking??

- Thread starter dakine97

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

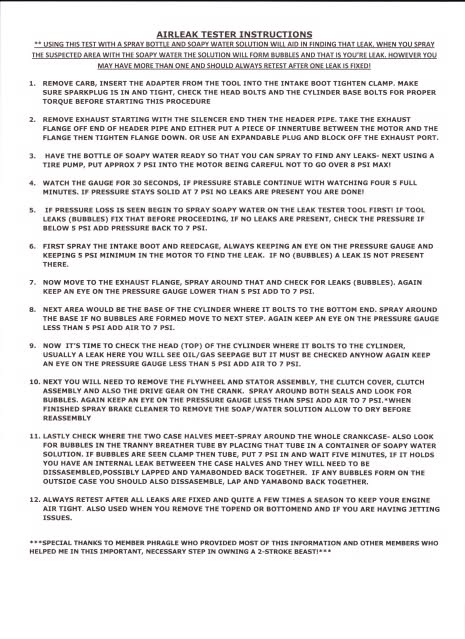

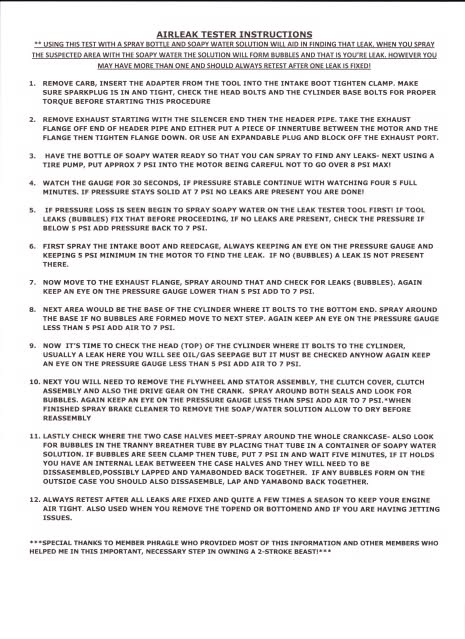

Have you done a leak down test lately, it sounds like you have developed an air leak.

What size main jet do you use with the mods listed.

What size main jet do you use with the mods listed.

That did not answer the question. Have you done a leak down test?

Fresh gaskets require that you to do a leak down test to see if they are air tight.

Are the new gaskets a bue/green paper composition type? If so they are very prone to leak.

If you are running a #340 main with your mods listed and getting detonation, I bet a penny to a pinch of crap that you have an air leak.

Do the following before you start it again, and then plug chop to confirm the main jet if it passes the test.

What octane rating gas are you using?

Fresh gaskets require that you to do a leak down test to see if they are air tight.

Are the new gaskets a bue/green paper composition type? If so they are very prone to leak.

If you are running a #340 main with your mods listed and getting detonation, I bet a penny to a pinch of crap that you have an air leak.

Do the following before you start it again, and then plug chop to confirm the main jet if it passes the test.

What octane rating gas are you using?

Last edited by a moderator:

It has fresh gaskets n my parts guy up at earlys said with my fresh gaskets its fine n I run a 340 main on a stock 26 mil carb

Although it may seem like logic, you cannot lean on a parts counter and determine with a bit of chat and a list of parts if your engine is leaking air or not. Air leaks are one of the most common and most serious problems with 2 strokes and Blaaster, sage and wizened gentleman that he is, has brought you straight advice from the other side of the world.

You cannot "guess" things right. You have to test.

Leak test, plug test, piston clearance, ring gap, squish gap, etc.

You have to check these things to be sure or you will be stunned by a blown up engine.

High speed spark knock or detonation is a rattle or change in note at top revs.

If you have a loud exhaust you may not even hear it. Power will drop off very slightly.

If all your mechanical issues are right (jetting, leaks, right plug, etc) your options are:

back timing off (retard it several degrees) move stator same direction as crank.

use better octane fuel

reduce your compression, usually a thicker basegasket, but for a Blaster I'd suggest cutting the chamber larger.

Probably more too, but this is a start.

like these guys said^^^^

the stock head should not be milled at all, it equals detionation. Should rechamber it for better outcome.

the stock head should not be milled at all, it equals detionation. Should rechamber it for better outcome.

I am concerned about you running a #340 main jet with your sig mods.

Your mods call for no more than a #290 or #300 main, smaller if you still have the air box lid on.

Plug chop to confirm the jet and if it does not show a too rich setting, do another leak down test.

Your mods call for no more than a #290 or #300 main, smaller if you still have the air box lid on.

Plug chop to confirm the jet and if it does not show a too rich setting, do another leak down test.

Oh boy, you don't know whether to advance or retard for spark knock, but your father just happens to have a leak tester and you are running 8:1 oil and cannot get enough gas to pass through a 300 jet but are going to solve it with a 30 mil fliatslide?

I don't think I can solve your problems...

I don't think I can solve your problems...

What you need to do to have chance to solve your problem is to do the following ......

Compression test.

Then leak down test. Do it yourself, it should hold 7psi for 10 minutes.

Toss that octane booster, it is taking the place of precious 93 octane fuel which your mods should run fine on.

Mix a good quality 2 stroke oil at 32:1.

Do a leak down test, just in case you forgot to do one, then do a leak down test to make sure you did it right.

A #340 main jet with your stated mods would just about run your motor in the depths of the Atlantic trench.

Post your findings after you have done a leak down test.

By the way did I mention that you should do a leak down test.8-|

Another thing you might like to try is to pull the flywheel off and see if the key is broken.

Compression test.

Then leak down test. Do it yourself, it should hold 7psi for 10 minutes.

Toss that octane booster, it is taking the place of precious 93 octane fuel which your mods should run fine on.

Mix a good quality 2 stroke oil at 32:1.

Do a leak down test, just in case you forgot to do one, then do a leak down test to make sure you did it right.

A #340 main jet with your stated mods would just about run your motor in the depths of the Atlantic trench.

Post your findings after you have done a leak down test.

By the way did I mention that you should do a leak down test.8-|

Another thing you might like to try is to pull the flywheel off and see if the key is broken.

What you need to do to have chance to solve your problem is to do the following ......

Compression test.

Then leak down test. Do it yourself, it should hold 7psi for 10 minutes.

Toss that octane booster, it is taking the place of precious 93 octane fuel which your mods should run fine on.

Mix a good quality 2 stroke oil at 32:1.

Do a leak down test, just in case you forgot to do one, then do a leak down test to make sure you did it right.

A #340 main jet with your stated mods would just about run your motor in the depths of the Atlantic trench.

Post your findings after you have done a leak down test.

By the way did I mention that you should do a leak down test.8-|

Another thing you might like to try is to pull the flywheel off and see if the key is broken.[/QUOTE

I run 32:1 with either lucas 2 stroke mix or yamalube sometimes redline

will do and dad told me he needs to get his air tools back so we can advance my timing a little bit more but 30 mil wouldnt help at all..cause when its tapped on topend it wants more gas but it floods on bottom end

you should not need a air tools to do a timing adj. YOU SHOULD NOT USE ANY AIR TOOLS ON A BLASTER MOTOR AT ALLL. Maybe in some cases.

BUT NEVER ON THE END OF THE CRANK!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

I wanna pic of that leak test!!!!!!!!!!

throw the octain booster across the yard. YOU DONT NEED ITTTT!!!!!

Im almost garenteeing you your 340 main jet is WAYYY TO BIGGG!!!!!! unless ur under the ocean, where theres air.....:-/

advancing your timing with make your knock WORSE!!!!

NOW if your motor runs best with a 340 main your motor is eather hauling ass!!!!! with a stock design head.......8-| OR YOU HAVE A MOFO AIR LEAK MY SON!!!!!!!!!

Liston to the advise givin to you^^^^^^^^^^^^^^

with my experience im guessing your head is whats givving you most problems. BUTTT your super octain booster should make up for it. BUT since it isnt you got problems my friend..........

just a thought.....

you should not need a air tools to do a timing adj. YOU SHOULD NOT USE ANY AIR TOOLS ON A BLASTER MOTOR AT ALLL. Maybe in some cases.

BUT NEVER ON THE END OF THE CRANK!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

I wanna pic of that leak test!!!!!!!!!!

throw the octain booster across the yard. YOU DONT NEED ITTTT!!!!!

Im almost garenteeing you your 340 main jet is WAYYY TO BIGGG!!!!!! unless ur under the ocean, where theres air.....:-/

advancing your timing with make your knock WORSE!!!!

NOW if your motor runs best with a 340 main your motor is eather hauling ass!!!!! with a stock design head.......8-| OR YOU HAVE A MOFO AIR LEAK MY SON!!!!!!!!!

Liston to the advise givin to you^^^^^^^^^^^^^^

with my experience im guessing your head is whats givving you most problems. BUTTT your super octain booster should make up for it. BUT since it isnt you got problems my friend..........

just a thought.....

i use ait tools to take the bolts out that hold my cases and side cover on

i use ait tools to take the bolts out that hold my cases and side cover on

that would be one of those in some cases

that would be one of those in some cases.....

ya the impact gun works a whol lot better and faster than the impact driver

Similar threads

- Replies

- 0

- Views

- 361

- Replies

- 3

- Views

- 249