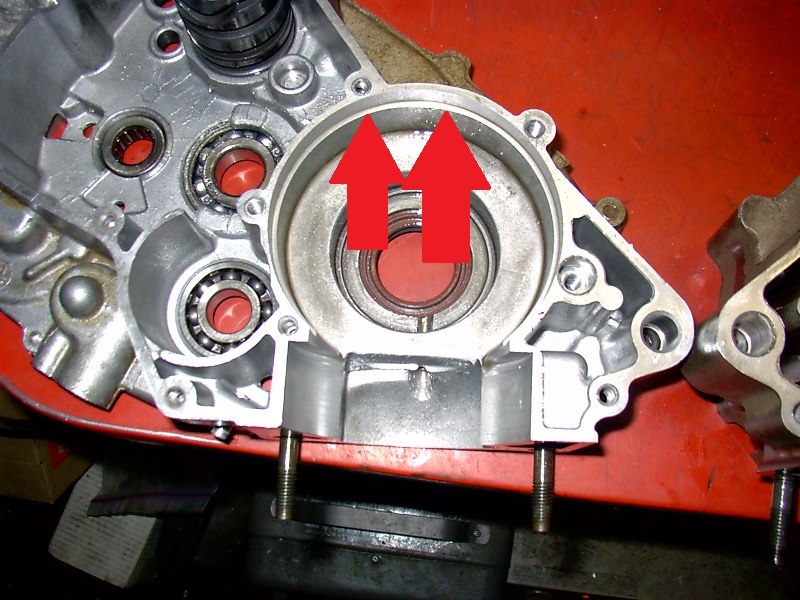

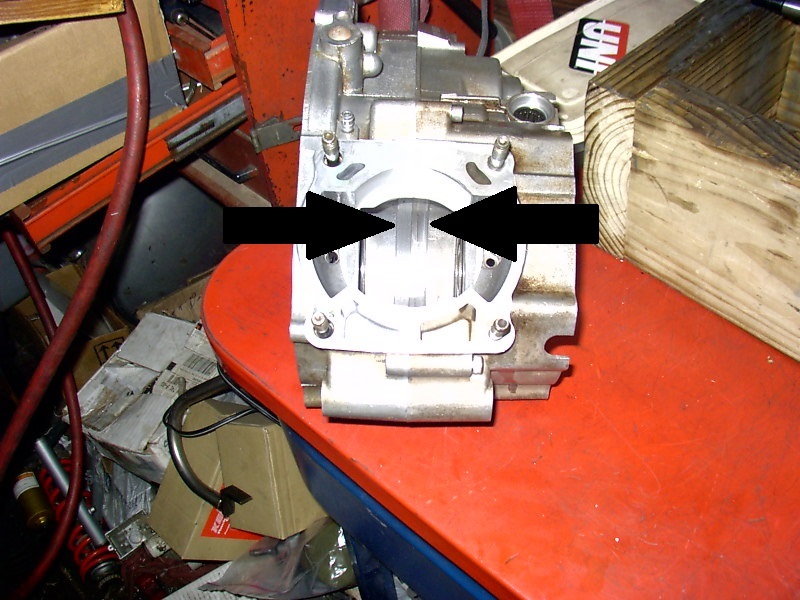

Hello all! First time posting and I have been very impressed with everyone's knowledge on this forum. Well the story begins with getting a " good deal" on a 2001 Blaster. I was told it had a new big bore kit a race Keihin carburator and a a new exhaust. It was never started with the new parts and had been stored for quite some time. The engine seemed hard to turn over so I took off the carb and reed vales squirted some oil on the rod and piston bearings. Inside the cylinder looked terrible. Must have had water get into the engine. A lot of rust and grime. Not knowing what to do, I sprayed some gas and oil mix repeatedly and wiped as much as I could. Looked a little better, re oiled the bearings and moved on to the carb. The engine did turn over a lot easier. The carb was full of rust and junk too so I took it apart and soaked in cleaner and reassembled. I was able to get it started and it ran ok. Was pretty gental on it and then it died. Took off top end and found a stiff rod bearing. I was thinking about doing the bottom end myself, but does anybody know someone in Colorado? It has a 240 cylinder, the Keihin Pwk has a 55 and 168 jets (it smoked a little but the spark plug was tan) no oil pump, 32-1 gas mix. I figure just the dirty inside caused the bearing to go and not the carb setting. I watched the Conner videos, its pretty involved, but I might be able to do it. Is there a step by step Manual that could help with steps, exploded views and torque settings. Any advise would be much appreciated. It's a real bummer, it ran good four a couple days and was a lot of fun. I thought I did get a good deal.

Please help......

Please help......

Last edited: