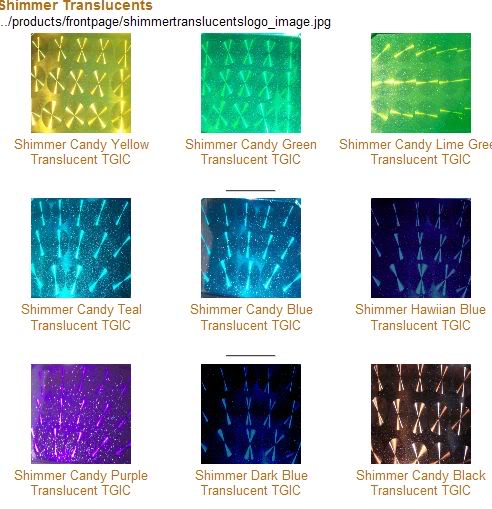

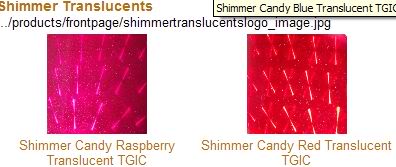

I know you guys like powder coating versus the wet painting method because of the durability. Even tho is can be costly in some geographical areas, it is well worth it. Well guys As I promised i would help as much as I could for the beginners wondering about this hobby and at least put some info in the guys heads that are awesome at powder coating as well. I'll start by posting color charts. Everyone sees' powder coating as black and white. This was my initial reaction...how boring is this stuff! Then as I researched...I have grown to love the varieties you are offered! Well enough babbling...check these links out!

Caswell Inc. - Indoor, Metallic, Candy, RAL and High Temperature Powder Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

http://store.columbiacoatings.com/c...ion&searchstart=12&keywords=all&category=MTPW

http://store.columbiacoatings.com/cgi-bin/commerce.cgi?search=action&category=SEPW&keywords=all

http://store.columbiacoatings.com/c...ion&searchstart=12&keywords=all&category=SEPW

http://store.columbiacoatings.com/cgi-bin/commerce.cgi?search=action&category=SHCC&keywords=all

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

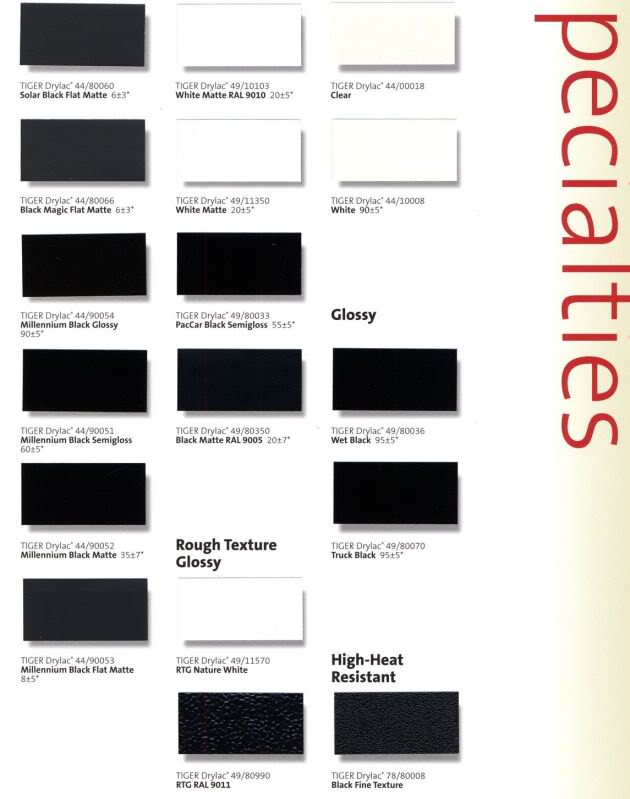

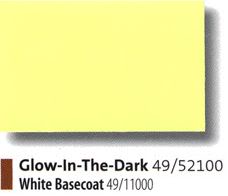

Here is what Tiger Drylac has to offer in their downloadable brochures of color charts:

TIGER Coatings: Color Charts / Brochures

Just take a gander at what they have to offer so this way you can customize your Blasters that noone else can duplicate!

Caswell Inc. - Indoor, Metallic, Candy, RAL and High Temperature Powder Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

http://store.columbiacoatings.com/c...ion&searchstart=12&keywords=all&category=MTPW

http://store.columbiacoatings.com/cgi-bin/commerce.cgi?search=action&category=SEPW&keywords=all

http://store.columbiacoatings.com/c...ion&searchstart=12&keywords=all&category=SEPW

http://store.columbiacoatings.com/cgi-bin/commerce.cgi?search=action&category=SHCC&keywords=all

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Columbia Coatings

Here is what Tiger Drylac has to offer in their downloadable brochures of color charts:

TIGER Coatings: Color Charts / Brochures

Just take a gander at what they have to offer so this way you can customize your Blasters that noone else can duplicate!