Hello,

I just had a weisco piston and twenty over bore. Reason for new pistion was the stock one started to have the skirt break off, and had some slop in it. Bearings looked to be in very good condition and eveything went back together very snug. I did a proper break in using lucas 2cycle oil mixed at 32 to 1. Everything seemed to be going smoothly, then about 2 hour after break in i started to get a sloppy knock come from the top end. And im 99% sure it is comeing from the top end.

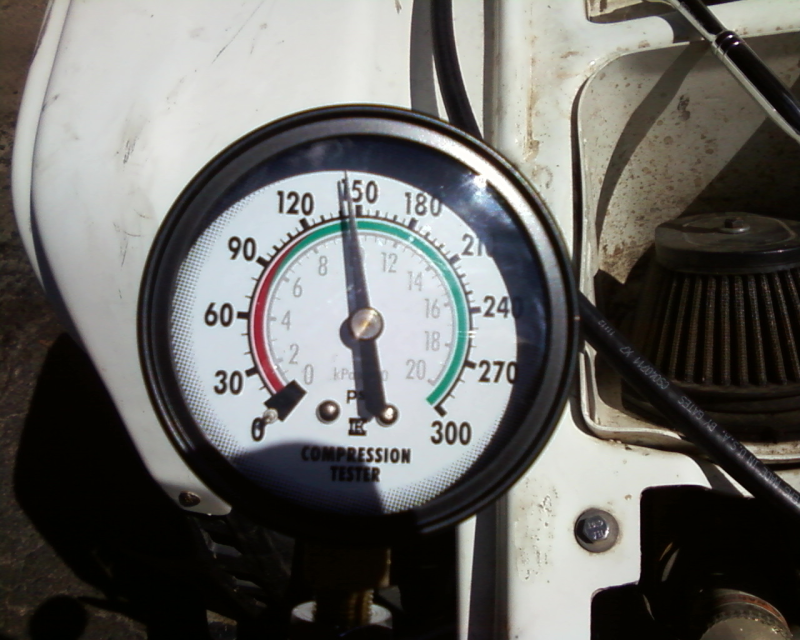

Here i have some pictures of the cyclinder and a crappy video of it running (atleast you can here it run in the video) Im just not liking the sound. Im just no liking the sound of this knock.

Please let me know what you guys think. I just spent alot of money fixing this up and i dont wanna break anything more then it may possibly be. I just dont think the cyclinder wore that much that quick cause i can still see the hone marks

Once again, sorry for the crappy video. My junky phone is all i have

Please let me know what you guys think

Thanks

I just had a weisco piston and twenty over bore. Reason for new pistion was the stock one started to have the skirt break off, and had some slop in it. Bearings looked to be in very good condition and eveything went back together very snug. I did a proper break in using lucas 2cycle oil mixed at 32 to 1. Everything seemed to be going smoothly, then about 2 hour after break in i started to get a sloppy knock come from the top end. And im 99% sure it is comeing from the top end.

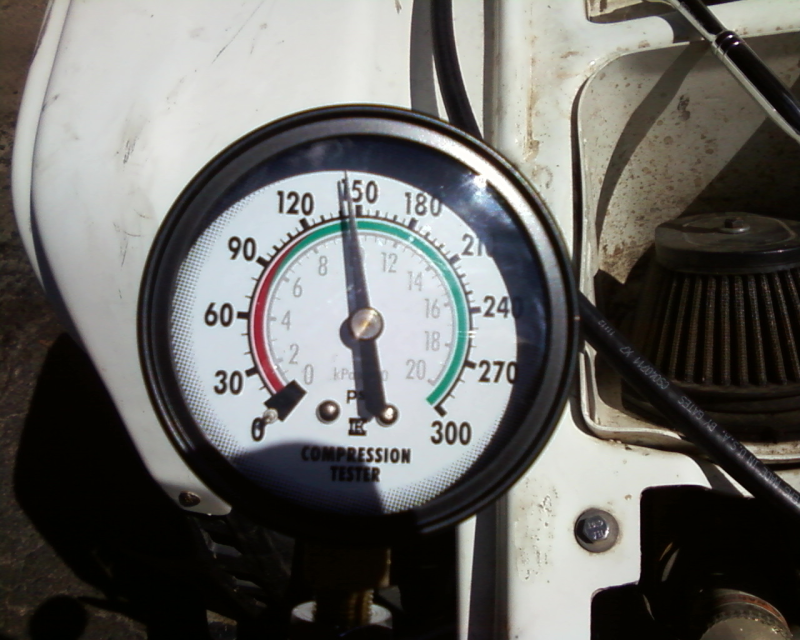

Here i have some pictures of the cyclinder and a crappy video of it running (atleast you can here it run in the video) Im just not liking the sound. Im just no liking the sound of this knock.

Please let me know what you guys think. I just spent alot of money fixing this up and i dont wanna break anything more then it may possibly be. I just dont think the cyclinder wore that much that quick cause i can still see the hone marks

Once again, sorry for the crappy video. My junky phone is all i have

Please let me know what you guys think

Thanks