Most people treat timing as a sort of mystical "black box" that should only be dabbled in by the most experienced of people. The truth is, timing is a relatively simple concept that is INSANELY difficult to implement. Part of the reason for the "black box" thinking is because of a lack of information or a lack of understanding about the principles involved.

The reason for the difficult implimentation is because it's much like hitting a moving target, while moving, without using using your eyes.

Timing for a spark ignition engine is absolutely crucial. It's what makes the engine do "the work" and any in-efficiencies in the system will show themselves as a lack of "potential power".

First, the theory. Most folks assume that the piston gets to the top of the cylinder, and the spark plug goes boom and the fireball pushes the piston down. That's...... naive but the simple jist of the operation. In reality, the spark plug neither "goes boom" or waits for the piston to be at the top.

When the engine is idling (or more importantly starting) you do want the spark to happen right at TDC. That way the engine isn't trying to "turn backwards" (remember, advanced means BEFORE top dead center when the piston is still rising) and is easier to start. Kickstart engines this is ESPECIALLY true because kickbacks hurt.... a lot!

Once the engine is running, there is fuel being sucked in compressed and ignited. This is all happening VERY fast (even at idle!) and while we think of a gasoline explosion as happening instantaneously (we've all seen cousin fred light up the backyard like a roman candle by pouring gasoline on a bonfire haven't we?!) a gasoline explosion DOES NOT happen instantaneously. It takes a few milliseconds for the flame front to stretch from the spark plug gap to the edge of the piston. Maximum power involves burning as much of the fuel and oxygen as you can on every stroke. Part of what makes a rechambered head so efficient is that it centers the "charge" around the spark plug meaning it takes less time for the flame front to reach about 90% of the total charge.

In order to make that explosion (and thermal and chemical expansion) happen before the piston is falling again, you actually need the explosion to start BEFORE the piston reaches the top of the cylinder. This is called timing advance. In other words, how early in milliseconds or degrees of crankshaft rotation before the piston reaches top dead center (TDC) will the spark event have to happen in order for the flame to extert pressure on the piston crown when the piston is AT TDC.

Making the explosion start too soon will result in predetonation (the explosion reaches the piston surface before the piston is at TDC and "jarrs" the piston downward). Making the explosion start too late and the flame front will "chase" the piston as it falls.

VERY rare occasions will the timing actually be retarded (the spark doesn't occur until after the piston has passed TDC) so when someone talks about "retarding" the timing they're talking about from the factory set point (or the current setpoint of advance).

The faster the engine turns, the sooner (in degrees of crankshaft rotation) the spark needs to happen in order for the flame front to meet the piston at the perfect time. This is REALLY where timing advance comes in.... because the top end power where most people try to tune their engines.

So now we have the theory... we spark before the piston is actually in position so that the flame and piston meet at the exact moment we need.

Now comes the tricky part; implimentation.

Let's take something simple, like a lawn mower engine. What we have is a magneto ignition (power generation and timing control built into one). Because MOST "lawnmower" engines (generators, pumps, weedeaters etc etc) only really are designed to operate at one specific operation or at least only really need to be efficient at one speed (governor speed or design speed)

They only have two modes of operation, one is "start" and the other is "run". The timing is setup so that it is advanced a certain amount for the "run" setting and the flame will hit the piston at the perfect amount during normal operation (3,600 rpm in the case of a B&S engine). The starting and off high rpm operation are not optimized (they're too advanced to be perfect) but that's ok. This allows a well tuned engine at the normal operation RPM with fewer parts and MUCH less complicated ignition system. It's a trade-off.

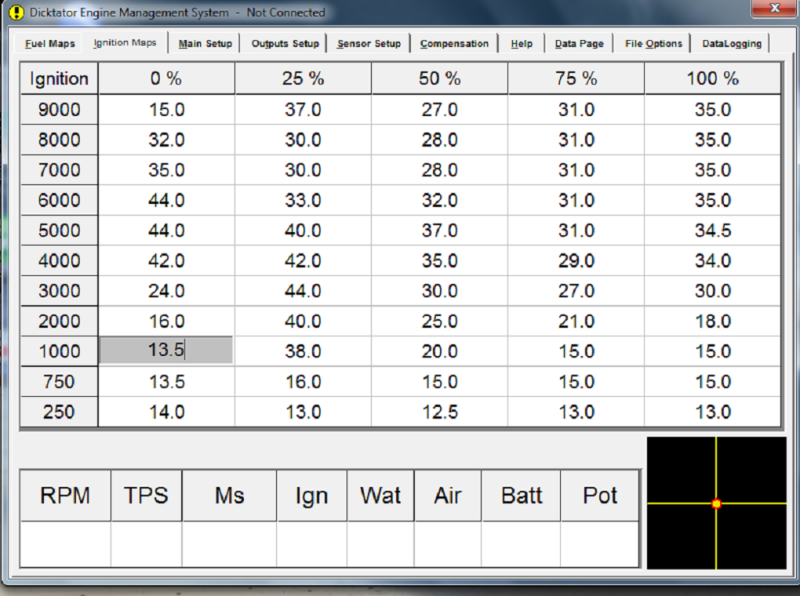

Contrast that with modern ignition systems controls. The ignition is completely fluid (the "timing" trigger is the crankshaft position sensor and/or camshaft position sensor) and controlled by the ECU based on some VERY complicated algorithms to advance and retard the timing to optimize the flame for every operational mode. Automobile engines have to be emissions compliant AND fuel efficient (those are actually hand in hand) but have the disadvantage of having to work over a BROAD range of conditions including high rpm high load (accelerating down the entrance ramp), high rpm light load (cruising on the interestate), low rpm high load (taking off from a stop light), and light rpm light load (idle). In order to optimize, the manufacturers use the crankshaft position, rpm, throttle position, engine temperature, air temperature, and even learned settings of how the driver drives (brand new vehicles believe it or not!) These are complicated algorithms for a very complicated system.

The compromise is a fairly basic system like we have on the blaster. It's a preprogrammed amount of "delay" from the maximum designed spark advance (built into the positioning of the trigger coil versus the flywheel) calculated by engine RPM. Think of it as a 2 column chart.

One column is current engine rpm (independent of load, temperature, driver) and the other column is timing "delay" from maximum advance. The "graph" is inverted to engine rpm so that there is no delay at high rpm's and delay basically equals the total available advance at idle (so the spark happens exactly at TDC)

Turning the stator plate (the "4 degree mod") increases the timing advance across the board (4 degrees more from idle to maximum RPM).

The reason for the difficult implimentation is because it's much like hitting a moving target, while moving, without using using your eyes.

Timing for a spark ignition engine is absolutely crucial. It's what makes the engine do "the work" and any in-efficiencies in the system will show themselves as a lack of "potential power".

First, the theory. Most folks assume that the piston gets to the top of the cylinder, and the spark plug goes boom and the fireball pushes the piston down. That's...... naive but the simple jist of the operation. In reality, the spark plug neither "goes boom" or waits for the piston to be at the top.

When the engine is idling (or more importantly starting) you do want the spark to happen right at TDC. That way the engine isn't trying to "turn backwards" (remember, advanced means BEFORE top dead center when the piston is still rising) and is easier to start. Kickstart engines this is ESPECIALLY true because kickbacks hurt.... a lot!

Once the engine is running, there is fuel being sucked in compressed and ignited. This is all happening VERY fast (even at idle!) and while we think of a gasoline explosion as happening instantaneously (we've all seen cousin fred light up the backyard like a roman candle by pouring gasoline on a bonfire haven't we?!) a gasoline explosion DOES NOT happen instantaneously. It takes a few milliseconds for the flame front to stretch from the spark plug gap to the edge of the piston. Maximum power involves burning as much of the fuel and oxygen as you can on every stroke. Part of what makes a rechambered head so efficient is that it centers the "charge" around the spark plug meaning it takes less time for the flame front to reach about 90% of the total charge.

In order to make that explosion (and thermal and chemical expansion) happen before the piston is falling again, you actually need the explosion to start BEFORE the piston reaches the top of the cylinder. This is called timing advance. In other words, how early in milliseconds or degrees of crankshaft rotation before the piston reaches top dead center (TDC) will the spark event have to happen in order for the flame to extert pressure on the piston crown when the piston is AT TDC.

Making the explosion start too soon will result in predetonation (the explosion reaches the piston surface before the piston is at TDC and "jarrs" the piston downward). Making the explosion start too late and the flame front will "chase" the piston as it falls.

VERY rare occasions will the timing actually be retarded (the spark doesn't occur until after the piston has passed TDC) so when someone talks about "retarding" the timing they're talking about from the factory set point (or the current setpoint of advance).

The faster the engine turns, the sooner (in degrees of crankshaft rotation) the spark needs to happen in order for the flame front to meet the piston at the perfect time. This is REALLY where timing advance comes in.... because the top end power where most people try to tune their engines.

So now we have the theory... we spark before the piston is actually in position so that the flame and piston meet at the exact moment we need.

Now comes the tricky part; implimentation.

Let's take something simple, like a lawn mower engine. What we have is a magneto ignition (power generation and timing control built into one). Because MOST "lawnmower" engines (generators, pumps, weedeaters etc etc) only really are designed to operate at one specific operation or at least only really need to be efficient at one speed (governor speed or design speed)

They only have two modes of operation, one is "start" and the other is "run". The timing is setup so that it is advanced a certain amount for the "run" setting and the flame will hit the piston at the perfect amount during normal operation (3,600 rpm in the case of a B&S engine). The starting and off high rpm operation are not optimized (they're too advanced to be perfect) but that's ok. This allows a well tuned engine at the normal operation RPM with fewer parts and MUCH less complicated ignition system. It's a trade-off.

Contrast that with modern ignition systems controls. The ignition is completely fluid (the "timing" trigger is the crankshaft position sensor and/or camshaft position sensor) and controlled by the ECU based on some VERY complicated algorithms to advance and retard the timing to optimize the flame for every operational mode. Automobile engines have to be emissions compliant AND fuel efficient (those are actually hand in hand) but have the disadvantage of having to work over a BROAD range of conditions including high rpm high load (accelerating down the entrance ramp), high rpm light load (cruising on the interestate), low rpm high load (taking off from a stop light), and light rpm light load (idle). In order to optimize, the manufacturers use the crankshaft position, rpm, throttle position, engine temperature, air temperature, and even learned settings of how the driver drives (brand new vehicles believe it or not!) These are complicated algorithms for a very complicated system.

The compromise is a fairly basic system like we have on the blaster. It's a preprogrammed amount of "delay" from the maximum designed spark advance (built into the positioning of the trigger coil versus the flywheel) calculated by engine RPM. Think of it as a 2 column chart.

One column is current engine rpm (independent of load, temperature, driver) and the other column is timing "delay" from maximum advance. The "graph" is inverted to engine rpm so that there is no delay at high rpm's and delay basically equals the total available advance at idle (so the spark happens exactly at TDC)

Turning the stator plate (the "4 degree mod") increases the timing advance across the board (4 degrees more from idle to maximum RPM).