A little background:

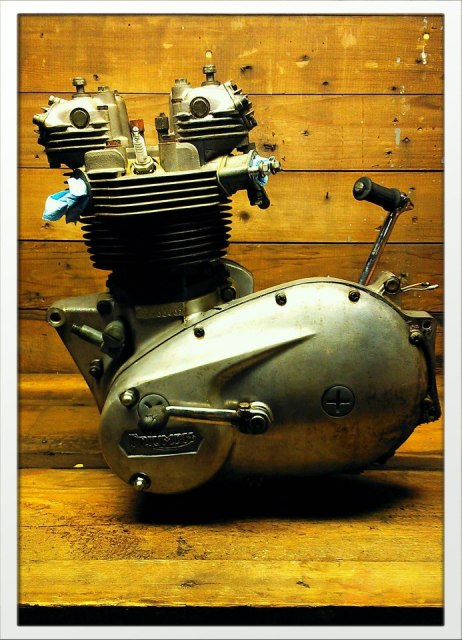

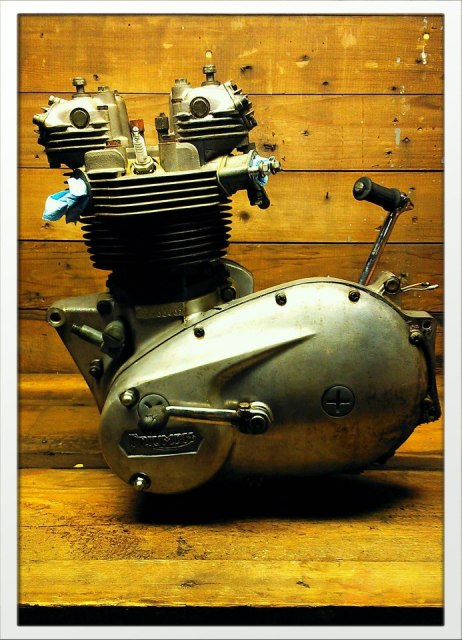

My coworker and I have been doing a ground up resto-mod on a 1978 Triumph Bonneville 750 that had been sitting for 10-20 years with an ignition failure. After replacing the CDI and rebuilding the carbs we got the bike running.

Next it was stripped down to bare frame for powder coating, paint, chrome and customization. While we were at it we we disassembled the engine to replace any out of spec. parts.

It turns out that the engine was rebuilt at some point and has 10 over Hepolite pistons/bores that look good and are in spec.

For the sake of performance and economy I would like to do a quick hone and replace the rings but herein lies the problem. After half a dozen e-mails to the top Triumph authorities in London it appears that none of them have seen +10 rings in nearly 30 years. Here is one of the e-mails:

"We no longer have stock on .010 rings. The 2 possibilities would be to file the .020 rings to .012” or larger end gap or fit standard rings.

A lot of people would shun me for that remark but end gap on unworn rings are not as much of an issue as end gap on worn rings.

Hepolite have tested engines with .012 gap and have increased the gap up to .060 with no difference in oil consumption as the ring is mostly in the ring groove so therefore only a tiny bit of the gap is exposed.

Sorry to run on like this but either of these options are viable."

My other two options are to reuse the rings that have been in the bike since the Reagan administration or punch the bores out to +20, buy an expensive set of pistons and kill my budget.

Sorry for the novel, what do you guys think I should do?

My coworker and I have been doing a ground up resto-mod on a 1978 Triumph Bonneville 750 that had been sitting for 10-20 years with an ignition failure. After replacing the CDI and rebuilding the carbs we got the bike running.

Next it was stripped down to bare frame for powder coating, paint, chrome and customization. While we were at it we we disassembled the engine to replace any out of spec. parts.

It turns out that the engine was rebuilt at some point and has 10 over Hepolite pistons/bores that look good and are in spec.

For the sake of performance and economy I would like to do a quick hone and replace the rings but herein lies the problem. After half a dozen e-mails to the top Triumph authorities in London it appears that none of them have seen +10 rings in nearly 30 years. Here is one of the e-mails:

"We no longer have stock on .010 rings. The 2 possibilities would be to file the .020 rings to .012” or larger end gap or fit standard rings.

A lot of people would shun me for that remark but end gap on unworn rings are not as much of an issue as end gap on worn rings.

Hepolite have tested engines with .012 gap and have increased the gap up to .060 with no difference in oil consumption as the ring is mostly in the ring groove so therefore only a tiny bit of the gap is exposed.

Sorry to run on like this but either of these options are viable."

My other two options are to reuse the rings that have been in the bike since the Reagan administration or punch the bores out to +20, buy an expensive set of pistons and kill my budget.

Sorry for the novel, what do you guys think I should do?