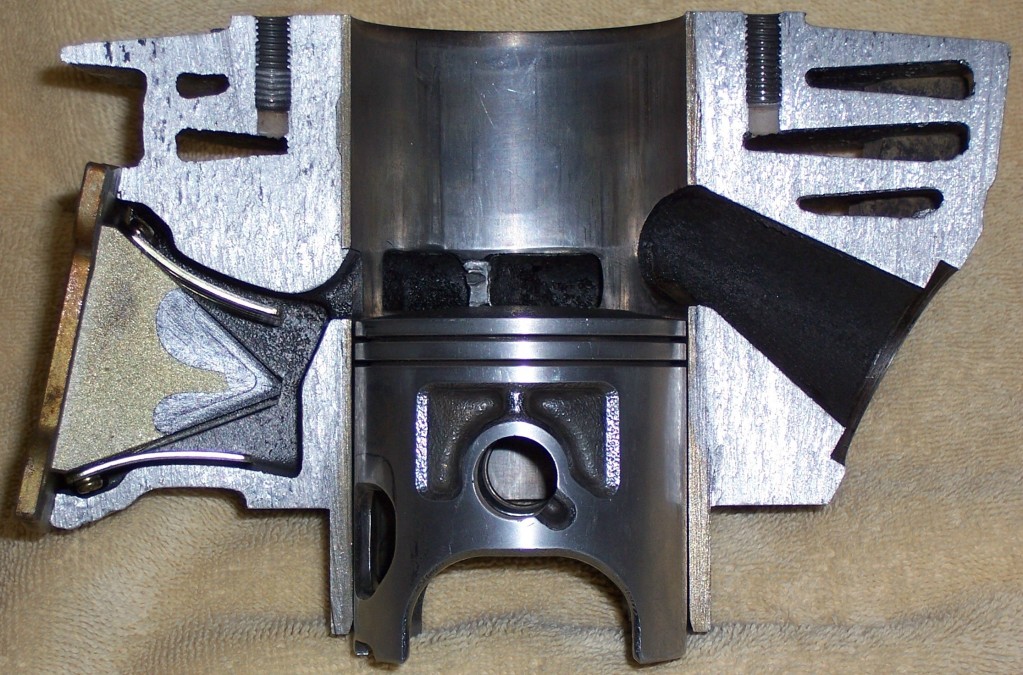

Yamaha Blaster Cylinder "CUT-AWAY" LEARNING TOOL!

- Thread starter joeak47

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Great posting Joe.

Food for thought.

I was amazed how roughly cast the inside of the transfers are.

Do we need to look at ways to smooth the walls of the transfers out some, or do they in their present condition aid atomisitiation.

Food for thought.

I was amazed how roughly cast the inside of the transfers are.

Do we need to look at ways to smooth the walls of the transfers out some, or do they in their present condition aid atomisitiation.

Thanks for sharing ... great stuff ... can you post some pics with the reed cage in place ... interested in the clearances

Do you have any aftermarket cages you could stick in there? ...

Do you have any aftermarket cages you could stick in there? ...

Great posting Joe.

Food for thought.

I was amazed how roughly cast the inside of the transfers are.

Do we need to look at ways to smooth the walls of the transfers out some, or do they in their present condition aid atomisitiation.

They aren't as rough in person. I believe they will all vary from cylinder to cylinder. In my opinion... the rough surface keeps the fuel air mixture in suspension. You could smooth everything,then sand blast /glass bead the surface to give it a matt surface. Its amazing to think how fast the velocity is through all these ports when the engine is running.

Imagine everything at say 8,000RPM! WOW! The cut away of the intake plenum will help me design my boysen cutting jig. Thats going to be cool.

I was also thinking about what would happen if you "dimpled" the inside of the entire intake plenum and exhaust port like the surface of a golf ball? Thats why a golf ball will travel like more than twice the distance of a smooth ball of the same size and weight. The dimples prevent the air from sticking to the ball. Less air resistance! That one has me thinking. It wouldn't take much to do it other than patience and a small spherical cutter which I believe I already have. That would be "thinking outside the box". I wonder if anybody has tried that already? And...if so what were the results?

Thanks for sharing ... great stuff ... can you post some pics with the reed cage in place ... interested in the clearances

Do you have any aftermarket cages you could stick in there? ...

There are a few with the reed cage in place. Picture #2 and #3. The only after market cage I have is the Vfoce 3's,but they're on my blaster.[/B]

Last edited:

damn, that is pretty neat man. how the hell did you cut it though?

Milwaukee "Deep Cut" port-a band (Hand held band saw)

Its an awesome tool! Its never let me down. It looks like this...

I was also thinking about what would happen if you "dimpled" the inside of the entire intake plenum and exhaust port like the surface of a golf ball? Thats why a golf ball will travel like more than twice the distance of a smooth ball of the same size and weight. The dimples prevent the air from sticking to the ball. I wonder if anybody has tried that already? And...if so what were the results?

I am fimiliar with dimpling and how it it works on a golf ball.

Would dimpling work on a concave surface as well as it works on a convex plane?

Or would detrimental eddys be created.

Yes dimpling has been done before on the intake ports of many four stroke engines. I have seen tons of car and truck heads with dimpling. I have also seen some TRX heads with them. Rare but they are out there. The theory makes sense. But I think theres plenty of factors that go into something like this such as dimple depth, spacing, and placement.

Would dimpling work on a concave surface as well as it works on a convex plane?

Or would detrimental eddys be created.

I "think" it would work equally well on a concave,convex,or flat surface.

Just like eddy currents with electricity,Its quite possible it could create "eddy air flows". I guess we'll have to find out.

But I think theres plenty of factors that go into something like this such as dimple depth, spacing, and placement.

I was actually thinking of copying a golf ball "exactly" in terms of depth and spacing.

Do you have any links?

I will look for the pictures and links. And I have also heard some people talking about this before. It seems that the dimples didn't necessarily INCREASE power output in terms of horsepower, but the engine required less advanced timing to make the power. And some people noticed that they could run slightly higher compression ratios because the dimples kept the fuel suspended and acted as an emulsifier. Some have even done this to the domes of the piston but I don't see much of an advantage there. I can only assume that it would cause some hot spots that could lead to predetonation. But this is all just talk until you test it on this specific engine. You never know how it would effect it. I have also seen some builders use a style of "step" in the intake to keep the charge suspended. There was a guy who had that patented on BMW's I believe. So steps would also be a good possibilty for improvement. It's all worth a try.

TRX450R Thread With Good Pictures!

Anyone heard of a "golfball port"? - Honda TRX Forums: Honda TRX 450R Forum

Suzuki LTZ400 Link:

Swirl Quench Dimples? - Suzuki Z400 Forum : Z400 Forums

An Engine You Guy's Might Be More Familiar With!:

SRP RACING

Anyone heard of a "golfball port"? - Honda TRX Forums: Honda TRX 450R Forum

Suzuki LTZ400 Link:

Swirl Quench Dimples? - Suzuki Z400 Forum : Z400 Forums

An Engine You Guy's Might Be More Familiar With!:

SRP RACING

Taking a well known phenomenon in a particular situation (golf balls) and trying to apply that logic to something else (engine guts) can sometimes have AWESOME results but can sometimes have dismal (or at least not measurable) results.

The thing about it, is WHY golf balls are dimpled. Golf balls are dimpled to increase the turbulence in the boundry layer around the surface. All perfectly round objects are subject to flow separation (remember the discussion about rounded intake tract parts versus knife edged) in an extreme manner. At a certain air speed the drag increases exponentially as the object moves faster as flow separation occurs. The trade-off with the dimpling is that it increases turbulence (and drag) at all relative air speeds but at that all important extremely high speed that a golf ball flies at on a long drive, the turbulent drag is less than the flow separated drag.

The thing about an intake tract (or head, exhaust etc etc) is that they operate at other than atmospheric pressure and not at the same flow rate throughout the engine operating regime. If the flow speed never reaches the point that flow separation occurs (and remember, at other than atmospheric pressure with the contours and flow direction changes occuring inside a blaster engine you can't take ANY flow speed for granted) those dimples are super time consuming turbulence generators that will slow down you intake charge.....

However, I don't know that they won't work FOR CERTAIN. Someone who has the time and energy to test should try it and let us know!

The thing about it, is WHY golf balls are dimpled. Golf balls are dimpled to increase the turbulence in the boundry layer around the surface. All perfectly round objects are subject to flow separation (remember the discussion about rounded intake tract parts versus knife edged) in an extreme manner. At a certain air speed the drag increases exponentially as the object moves faster as flow separation occurs. The trade-off with the dimpling is that it increases turbulence (and drag) at all relative air speeds but at that all important extremely high speed that a golf ball flies at on a long drive, the turbulent drag is less than the flow separated drag.

The thing about an intake tract (or head, exhaust etc etc) is that they operate at other than atmospheric pressure and not at the same flow rate throughout the engine operating regime. If the flow speed never reaches the point that flow separation occurs (and remember, at other than atmospheric pressure with the contours and flow direction changes occuring inside a blaster engine you can't take ANY flow speed for granted) those dimples are super time consuming turbulence generators that will slow down you intake charge.....

However, I don't know that they won't work FOR CERTAIN. Someone who has the time and energy to test should try it and let us know!

When we have our motors ported and the intake blasted, I bet if you took a strong magnifier the surface of the intake would appear dimpled, so the question would be if we increase those dimples does it help or hurt or no change?

I bet it takes a considerable amount of time to golfball dimple an intake! will the benifits of power be worth the effort?

Sure wish I had the tools to try some different things! Good luck and I'm sure you will report findings!

I bet it takes a considerable amount of time to golfball dimple an intake! will the benifits of power be worth the effort?

Sure wish I had the tools to try some different things! Good luck and I'm sure you will report findings!

dimples are super time consuming turbulence generators that will slow down you intake charge..... !

Would dimpling work on a concave surface as well as it works on a convex plane?

Or would detrimental eddys be created.

That is where I was aiming in not so many words, good explanation Civic.

I believe that the next modification to my blaster will be a "piston Boost port"

Looks like this...

This looks like a fun thing to try! I'm sure I could pick up 1 to 2 hp with this!

Plus... The added lubrication for the wrist pin,and the additional piston cooling.

Looks like this...

This looks like a fun thing to try! I'm sure I could pick up 1 to 2 hp with this!

Plus... The added lubrication for the wrist pin,and the additional piston cooling.

Last edited:

Similar threads

- Replies

- 4

- Views

- 538

- Replies

- 0

- Views

- 89

- Replies

- 19

- Views

- 356