Hello, I would like to start by letting you all know that I am new to the site and have recently purchased an older blaster that needs some work. I have been checking out and reading the site for the last month or so and really appreciate all the great info you guys give out. It is a really big help to have a resourse like this to get help on. I like to think of myself as somewhat mechanicaly inclined and like to turn a few wrenches. So I have a few questions before I start to tear it all apart.

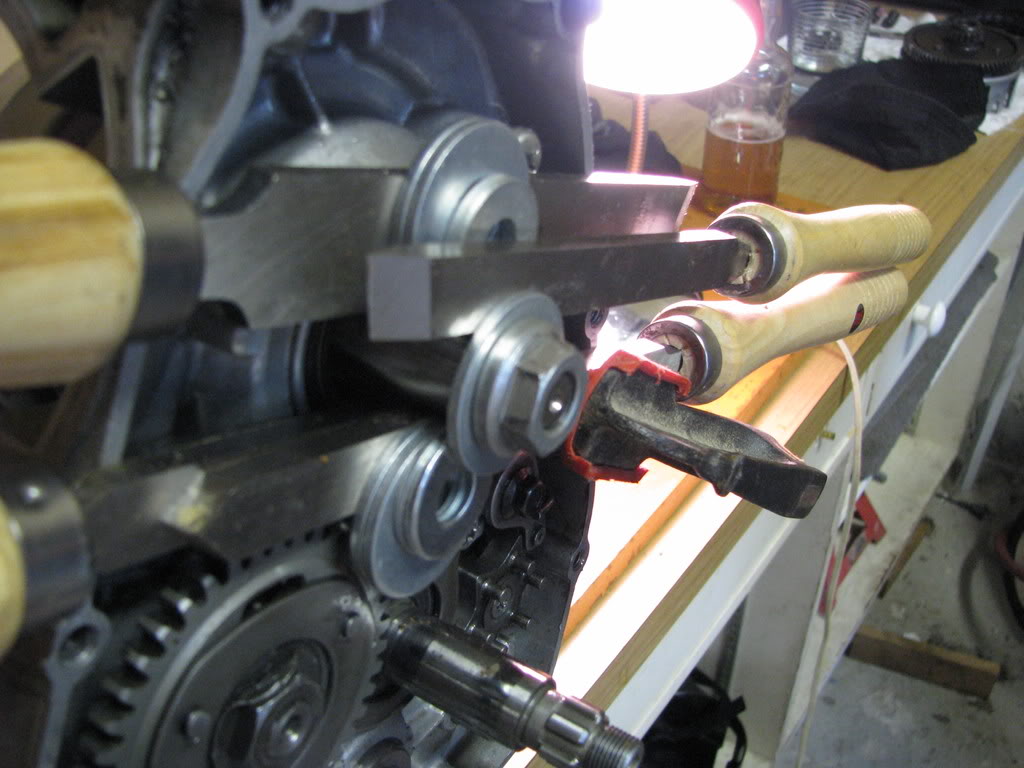

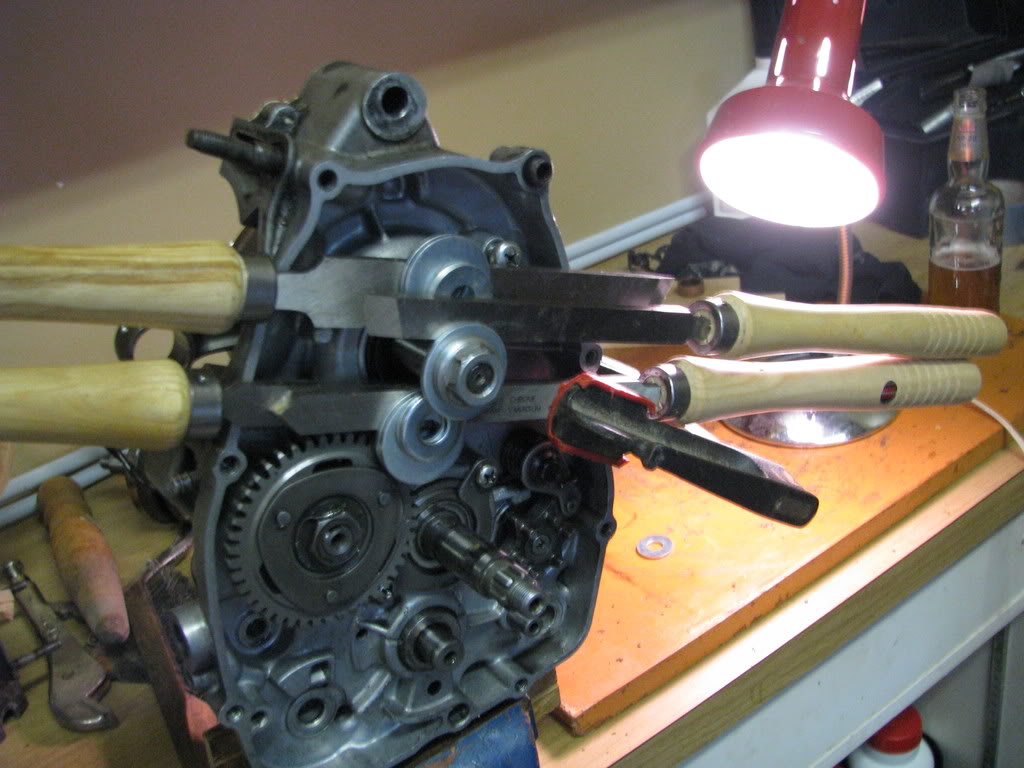

1. How hard is it to split the cases and put in a new crank? What are the little tricky parts to watch out for. What all parts should I purchase to do a bottom end rebuild? (new crank +3mm, seals, bearings, etc.)

2. When I have them motor all apart I would like to clean everything on the inside up as best I can. What is the best product to use to clean everything with?

3. Is there anything else I should replace or watch out for as a precaution while I have the cases apart?

That is all I can remember for now but I am sure I will have more as soon as I get into it.

Thanks in advance for any and all advice you might share.

Dustin

1. How hard is it to split the cases and put in a new crank? What are the little tricky parts to watch out for. What all parts should I purchase to do a bottom end rebuild? (new crank +3mm, seals, bearings, etc.)

2. When I have them motor all apart I would like to clean everything on the inside up as best I can. What is the best product to use to clean everything with?

3. Is there anything else I should replace or watch out for as a precaution while I have the cases apart?

That is all I can remember for now but I am sure I will have more as soon as I get into it.

Thanks in advance for any and all advice you might share.

Dustin