Project MonkeyBlaster

- Thread starter C-Bass

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looks great! Nice job! Tell monkey is color pick is awesome! Green is my favorite color

thanks, he'll be happy to hear it gets the thumbs up from "the guys"

i was just saying because they look some what like awks gsxr breaks

i think he suggested the gsxr upgrade when i posted the pic earlier, so I'm guessing they're from something else

Nice work

That green is lush.

Thats the coulor i am going to go with!

Thanks,

Officially the paint is classified as a yellow color...but as far as I'm concerned it's green to me too

The other color chosen was this blue, and since the plastics are being rattle canned in this Krylon Fusion color, it was decided that there should be some blue accents also.

old gas tank cover

Kryloned

That blue is a really nice coulor as well.

I would go green frame with blue a arms and swingarm and green carrier.

Great spraying as well , Every time i try spray things allways comes out bad Lol

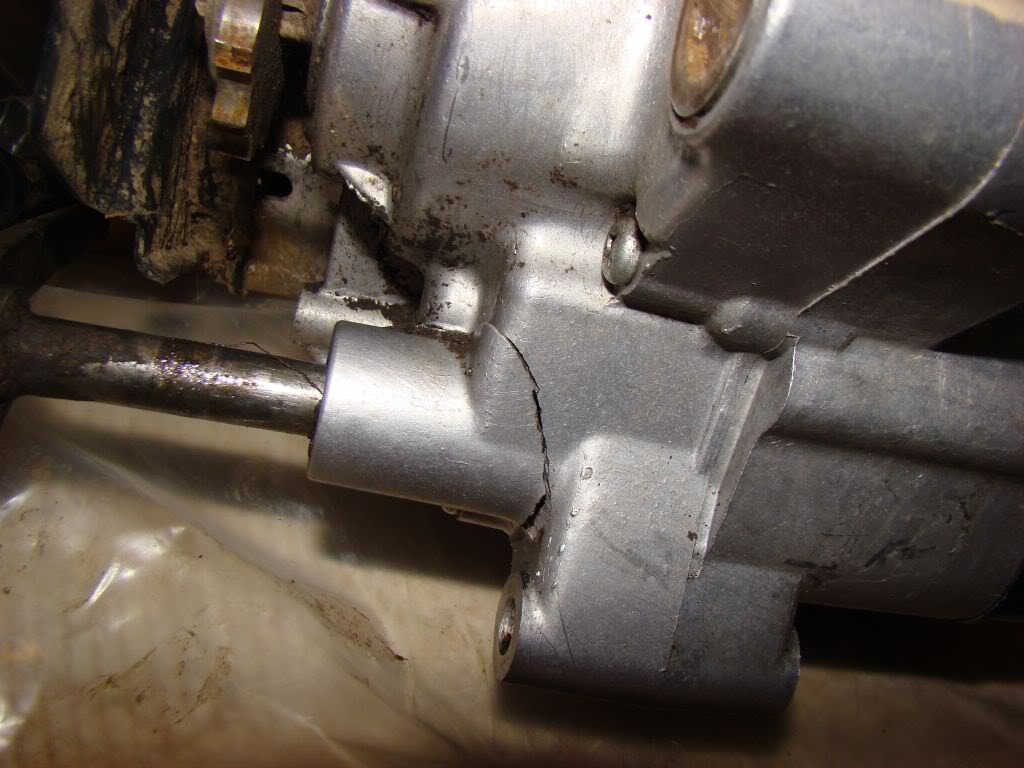

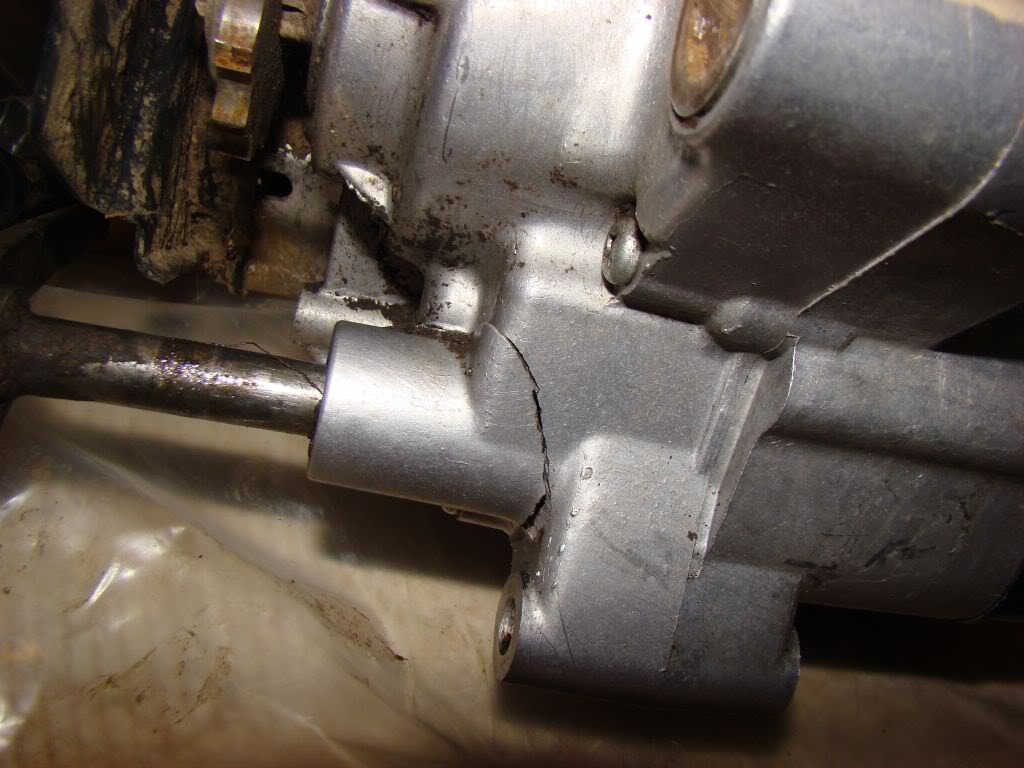

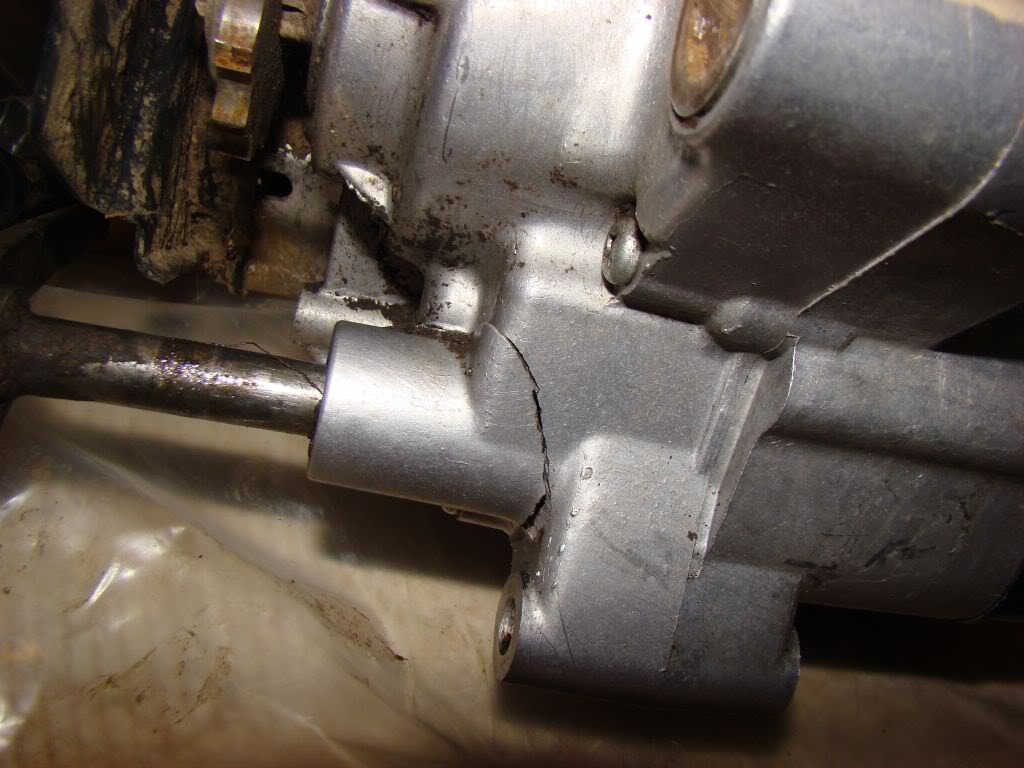

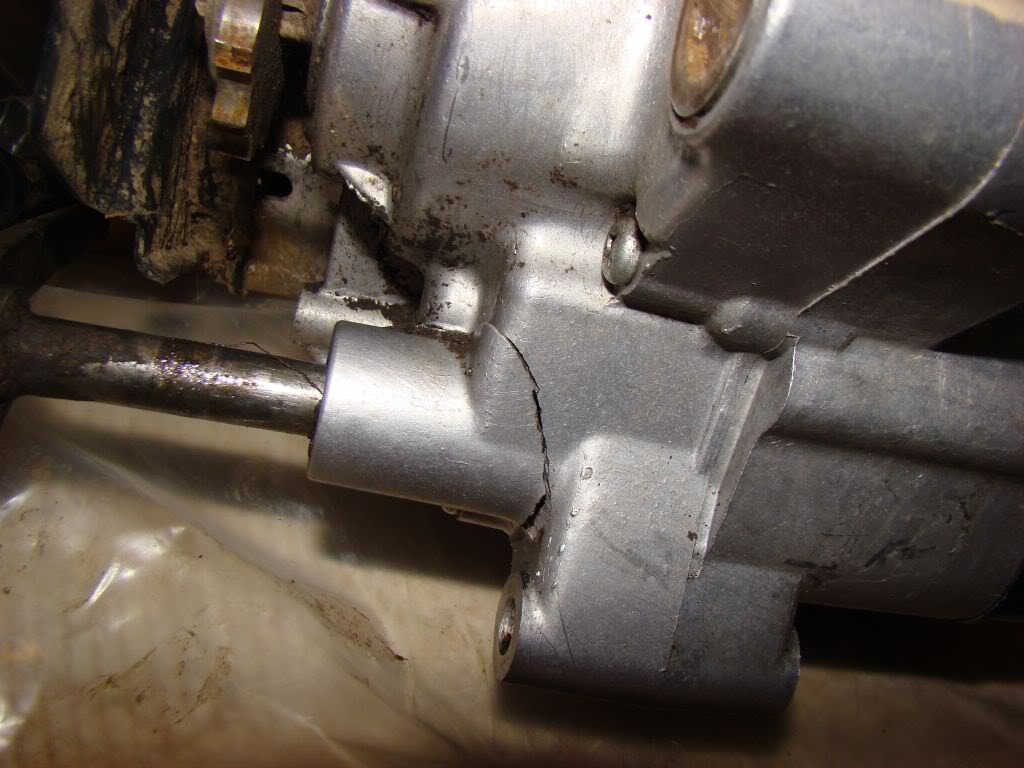

Here's the engine out of the 2nd lot of parts.

There is a crack all around the end of the casing where the gear shifter comes out which I'm hoping i can get welded. First guy I talked to was a moron, the next guy was recommended by someone I know and after talking to him it sounds a lot more promising.

The rest of the engine looks to be complete and in decent shape.

There is a crack all around the end of the casing where the gear shifter comes out which I'm hoping i can get welded. First guy I talked to was a moron, the next guy was recommended by someone I know and after talking to him it sounds a lot more promising.

The rest of the engine looks to be complete and in decent shape.

Here's the engine out of the 2nd lot of parts.

There is a crack all around the end of the casing where the gear shifter comes out which I'm hoping i can get welded. First guy I talked to was a moron, the next guy was recommended by someone I know and after talking to him it sounds a lot more promising.

The rest of the engine looks to be complete and in decent shape.

AWESOME JOB SO FAR!!!!Especially if this is your first build!!

Anyhoo youve bought a bunch of parts i see why not just replace the case halve with another?Im sure in all the odds and ends you got theres a spare case halve?

Id advise against welding if you can just replace the case halve.Splitting the cases is not a big deal.You could have that thing swapped and back together in a few short hours.

did you clean all the old paint off?

i stripped all the old paint off the frame and anything else that was rusted down to bare metal. other pieces that only needed a color change or had light surface rust, i sanded down lightly so the new paint would stick.

AWESOME JOB SO FAR!!!!Especially if this is your first build!!

Anyhoo youve bought a bunch of parts i see why not just replace the case halve with another?Im sure in all the odds and ends you got theres a spare case halve?

Id advise against welding if you can just replace the case halve.Splitting the cases is not a big deal.You could have that thing swapped and back together in a few short hours.

the case halves that i do have as spares aren't good. the one in good condition is the wrong side. the next best one has a hairline crack and some bad bearings.

why would you advise against welding?

i am trying to avoid dissassembling things unless i absolutely have to.

the minute i crack this thing open i need a new gasket set no? then a case half and the list starts from there. I don't like spending $$ if I don't have to.

Here's the engine out of the 2nd lot of parts.

There is a crack all around the end of the casing where the gear shifter comes out which I'm hoping i can get welded. First guy I talked to was a moron, the next guy was recommended by someone I know and after talking to him it sounds a lot more promising.

The trouble with repairing that area is alignment.... You have to be VERY careful to notch out a handful of areas for filler without mssing up the factory "break line" ina few places to make sure that the piece stays where it was supposed to be. THEN you have to go back and V out the areas left after there are a few weld spots to hole it in place. Take some time and patience and most welding shop don't do that sort of thing so they don't want to mess with it.

Budget_blaster, why would you throw away a set of cases that can be repaired? One day blaster cases will be rare and people will be kicking themselves for not repairing the repairable. Remember, they haven't made any new ones since 2006....

I dropped off the motor at the welder's yesterday. I got a good feeling about this guy. Super clean and organized shop, asked the right questions etc,

We'll see what happens, supposed to be ready today.

I'm also insulating and drywalling my computer room, hence the slow updates this week.

We'll see what happens, supposed to be ready today.

I'm also insulating and drywalling my computer room, hence the slow updates this week.

Similar threads

- Replies

- 0

- Views

- 142

- Replies

- 11

- Views

- 690

- Replies

- 5

- Views

- 223