The typical way that most people approach porting is to look over what they have seen or read other people have done,

imagine bigger is better, and have at it, or pay someone else to have at it.

Everything gets made bigger, all at once and the cylinder gets put back on.

Sometimes it works better, they feel success.

Sometimes it works worst, they feel cheated.

Winning racers go at it systematically.

They read all the theory and they look at what other winner's are doing.

Unfortunately if there is money in it, most winners don't share their secrets.

In fact, they usually lead the competition astray. Most often what you see shown off is "Hey look at me, mine is bigger!" photos.

Has no connection with more power at all.

So what do the winners do? One step at a time.

Take the exhaust port, raise it a little at a time until best effect.

Try a few different head designs, progressively and watching the variables.

Then take the intake, open it up a bit or fill it and see the effect.

Cut a little metal off or fill in a little, watching and reacting to the positive effects, not the visuals.

One step at a time, reassembling and testing at each change, comparing power gain or loss each time.

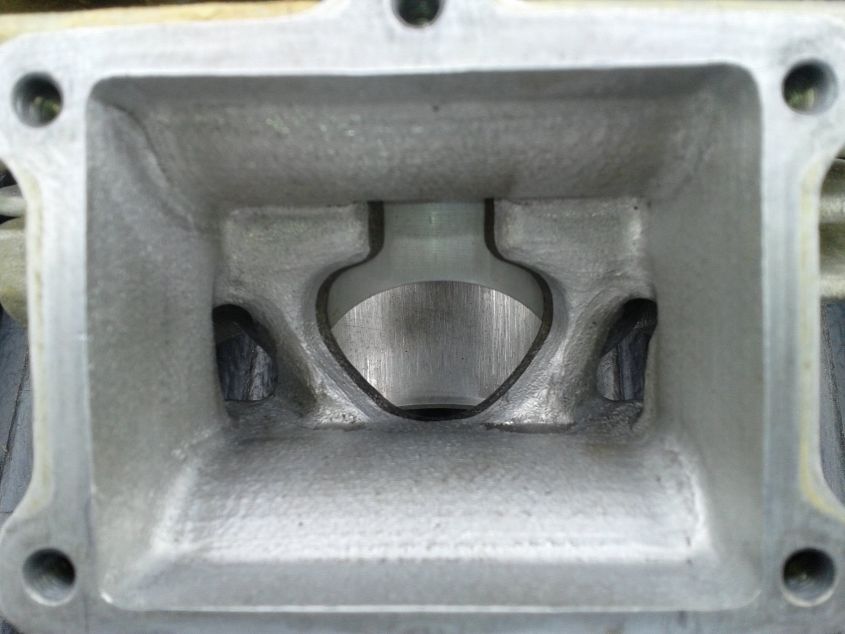

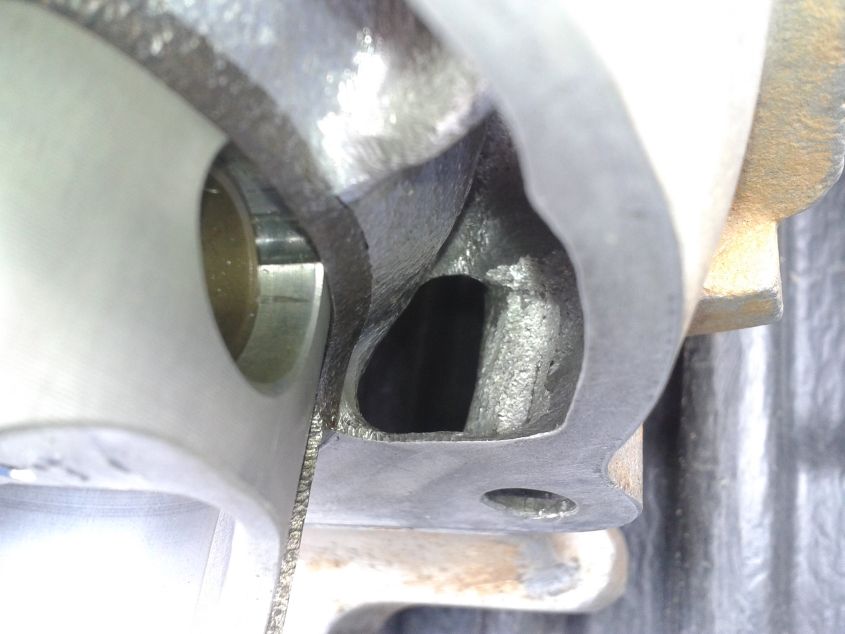

I just saw that picture of the "Monster" Boyesens and wanted to share.

Those Blaster ones are awesome James! How did they work?

When I do them, I will likely start small and watch for effect.

If the engine gets slower with 6mm Boyesens, and even slower with 8mm, why go more?

How do you know if the Boyesens are a good thing if you did your exhaust at the same time?

It takes all of 20 minutes tops to pull the cylinder on a Blaster, make use of that simplicity. Do things one step at a time.