AND...This can be done when the engine is assembled regarless of what "other" people will tell you!

If you have your engine apart for that "full rebuild",then this is the time to do it the "easy" way, but...

If its assembled,you can still do it...YOURSELF!

You will need some ...

#1 Paper towels

#2 masking tape

#3 A base gasket that has been matched to your cylinder (stock or ported)

#4 A Shop vac with a small tip

#5 A friend to help with the shop vac

#6 A scribe and marking compond to "match" the base gasket to the case

#7 A dremel,assortment of hand files,rotory files,sand paper,or pocket knife

#8 Common sense

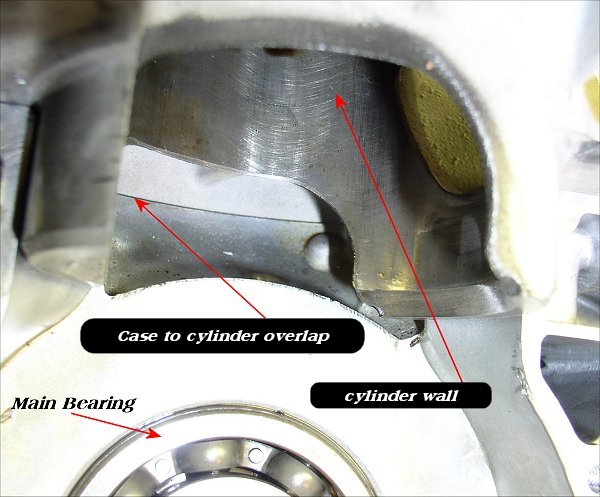

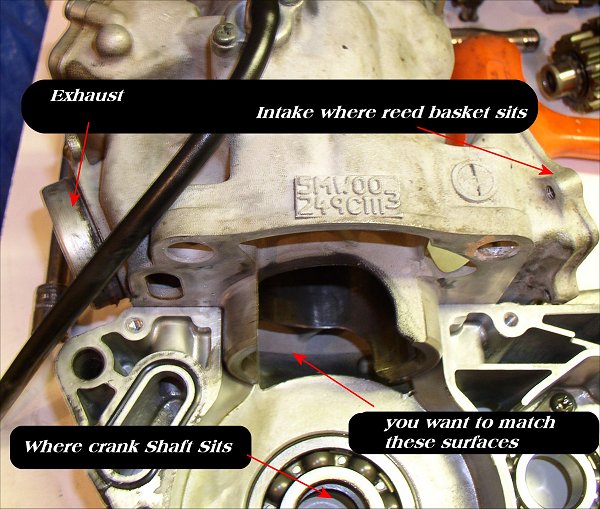

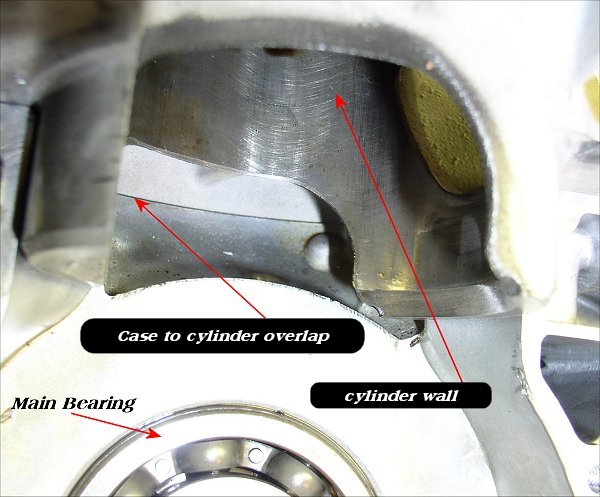

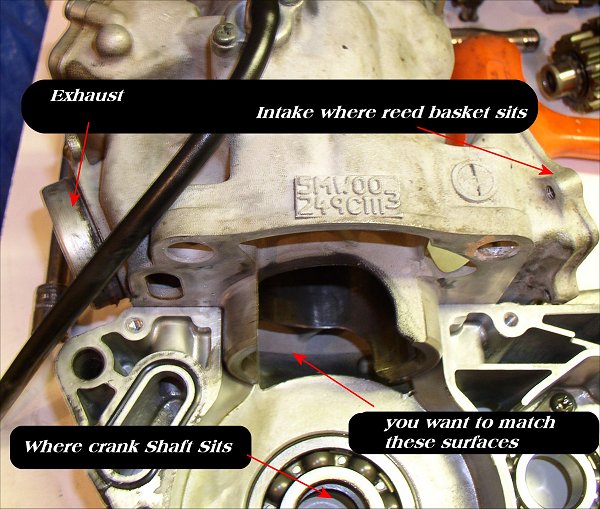

Port matching the engine case to the transfer ports on the cylinder. This can be done while the engine is assembled....if done with caution. This can make a HUGE difference!

This engine had its tranfer ports of the "Aggresive trail ported" cylinder matched to the engine case while the engine is assembled,and while it is still installed in the frame.

This can be done! It also works VERY well! Why cheat yourself out of power that the cylinder can produce? It took longer to prepareand tape than to actually cut and blend. The cutting and blending took about 7 minutes. Some cases require alot of material to be removed. Some very little.

This picture shows how you must properly tape the opening of the case to prevent aluminum chips from entering the case. The job is already completed in this photo

Here is another shot of the tape job. While I was using the carbide double cut bit (6" long) I also had the hose of a small shop vacuume within an inch or two of the bit to evacuate the chips. The blue dykem is just a die I use to see my scribed lines. Other things work just as well...paint,marks-A lot pen,etc,etc.

Here is a picture after the tape was removed,paper towels pulled out of the case,and dykem (blue dye) was removed.

What you're going to use the shop vac for,is to suck up any metal particles and debris why your "cutting and blending" to the scribed line. This is where the "friend" comes in handy. Get the shop vac tip very close to the work,and you will notice that when your done that there will be NO debris what so ever.

the tape will be enough to prevent any debri from entering the engine. It works very well. The trick is to have everything oil free,so the tape will stick.. Before you lay down the tape,use some carb cleaner to de-grease the surfaces. Don't be lazy! Do it once and then do it again! Then stuff paper towels down into the spaces in the crank case to fill the voids. This gives support to to tape above,and creates another barrier to prevent anything entering the crank case.

Every case/cylinder match is different. Some times you will only need to take off just a "wisp" of aluminum,and this is where the "pocket knife",or "X-acto knife" comes in handy. YES a pocket knife or X-acto knife will cut aluminum!

Other times will require more material to be removed. Thats where the dremel,hand files,rotory files,etc come in handy.

REMEMBER THIS...

Don't just match to your scribed line,but "Cut & Blend" down a ways from the top of the case to create a nice

SMOOTHtransition. It will do no good to just take the sharp edge off but still leave a

"Bump" for the air/fuel mixture to

"Bounce off of" like a speed bump.

NO BUMPS!

Heres a good analogy >>>

You have an edge of a concrete pad sticking up on the side walk in front of your house that you constantly keep tripping on when you go check the mail. Its that edge where two pads of concrete don't match,because one is high that the other (mis-matched ports),so you decide to round off "just the corner" of the raised one with a grinder,so your shoe won't catch anymore,but your lazy and do a half ass job and literally just "round the edge",then discover that it still keeps tripping you every time you go get the mail. So..... you decide to

"Cut & Blend" the edge into the top of the concrete pad to match the other concrete pad next to it

(Matched port),and cure the problem once and for all.

Do it right...Do it once! This is FREE POWER! It only takes a few moments to do when you have your cylinder off. This is especially important with a ported cylinder.

It will take you longer to tape everything off and prep than it will to actually "Cut & Blend"

AND...You can do it all by yourself! >>> At home in your own garage!

Imagine that...Nothing like doing something right the first time.