ok there may be some of you who like me almost freaked out a little at the sight of your sheared or in my case sheared and broken shifter shaft.

now what happened is that the keyway that holds the shift star in place sheared and when it sheared it took a chunk out of my shift drum shaft with it talk about a bummer...

anyways it was accually a cheap fix..only cost like 2 cents in welding wire lol..

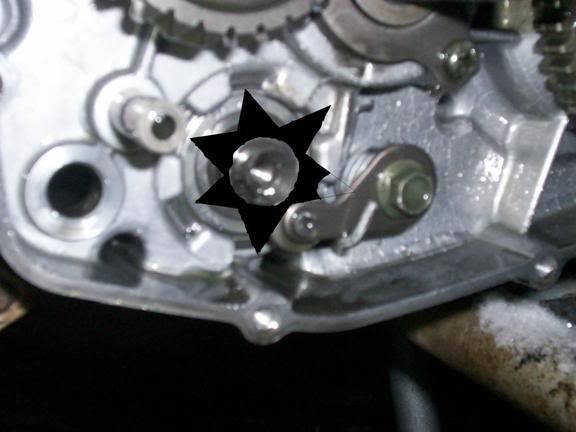

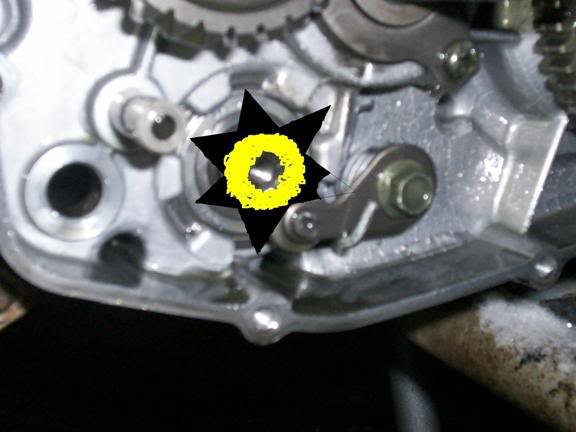

ok in this first pic you can see that the shaft has a chunk missing out of it (i know the pic is fuzzy but believe be its broken)

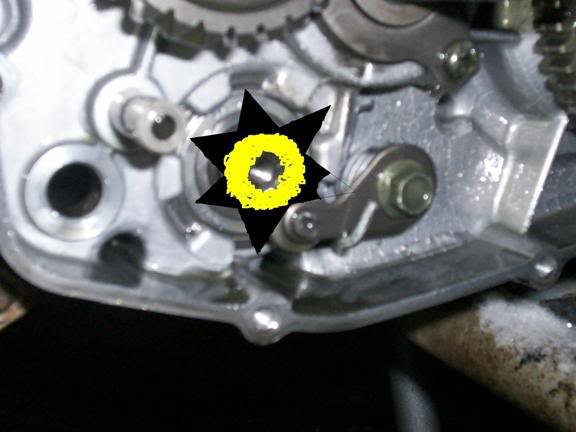

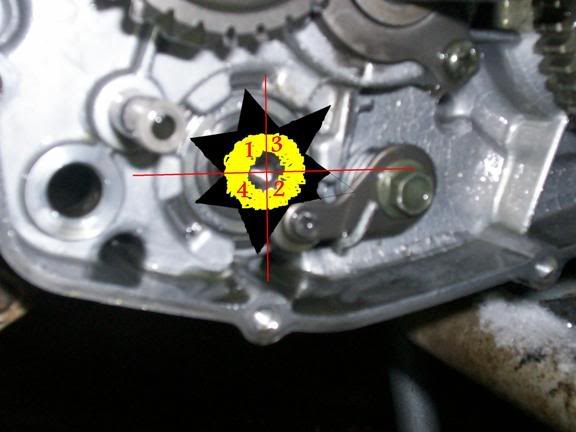

ok i dont take to many pics while i work so i drew this up with ms paint lol

so when you put the star back into place like the pic represents that is when you get out the welder we used a MIG welder and it worked great.

you wanna make sure you get good penetration and make sure you dont weld on the fingers on the star if you do then just file them off..

but this is kinda what you wanna go for..

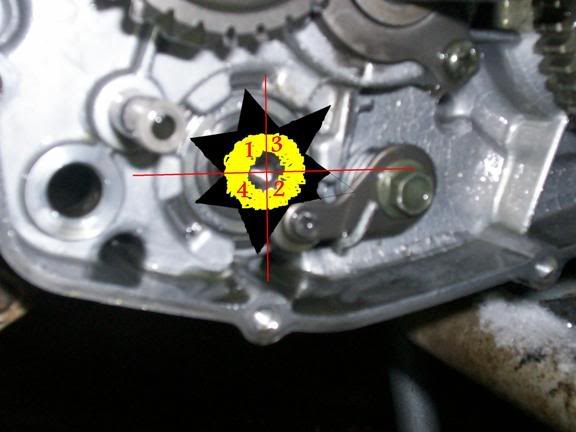

now the final pic i bet you are wondering why i divided it into 4 parts and that is because of HEAT!!!

im pretty sure these parts are cast and i dont have much experient with cast so to be on the safe side i divided the star into quarters like i welded in area #1 then i went to #2 and so on and i gave the part like a 20 second cool down period between steps so i didnt over heat the part....

and after that give the part a little while to cool down and then throw you blaster back together and GET BACK TO HAVING FUN!!!!

now what happened is that the keyway that holds the shift star in place sheared and when it sheared it took a chunk out of my shift drum shaft with it talk about a bummer...

anyways it was accually a cheap fix..only cost like 2 cents in welding wire lol..

ok in this first pic you can see that the shaft has a chunk missing out of it (i know the pic is fuzzy but believe be its broken)

ok i dont take to many pics while i work so i drew this up with ms paint lol

so when you put the star back into place like the pic represents that is when you get out the welder we used a MIG welder and it worked great.

you wanna make sure you get good penetration and make sure you dont weld on the fingers on the star if you do then just file them off..

but this is kinda what you wanna go for..

now the final pic i bet you are wondering why i divided it into 4 parts and that is because of HEAT!!!

im pretty sure these parts are cast and i dont have much experient with cast so to be on the safe side i divided the star into quarters like i welded in area #1 then i went to #2 and so on and i gave the part like a 20 second cool down period between steps so i didnt over heat the part....

and after that give the part a little while to cool down and then throw you blaster back together and GET BACK TO HAVING FUN!!!!

Last edited: