CFM aluminum airbox?

- Thread starter Druhh

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

it has the mounting hardware, but its a biotch!

search some posts. i have a few related to the airbox in both of my build threads. and i shared them to others

search some posts. i have a few related to the airbox in both of my build threads. and i shared them to others

Blaner

Your Friendly South African Ambassador

The right side of the box doesn't have a good mounting point. It wedges between the frame rails. The left side actually bolts to the frame. I found a huge washer and rubber washer and used it to grab on outside of frame.This is on my to do list, what exactly are the complications? some pics perhaps?

the right side comes with an aluminum dowel that is supposed to wedge in the frame. its okay but not the best design

Mine is that way too. With the large metal/rubber washer it helps keep the box in place. It's really sturdy that way.

I just got mine a couple weeks ago and was wondering the exact same thing about how to mount it. I had to order a longer coupler to connect the airbox to carb so that I could get the hardware to line up like the first picture that fast6hand posted. On the right side, I was thinking about just making some kind of bushing to wedge the one piece in tighter but the HUGE washer idea sounds better.

Hey man is there any chance you could send me the dimensions of this box going to fab one up myself

Don't bother:

Come up with your own design and it has to work better.

My son bought the CFM airbox and discovered less hp than his own previous inventions.

The design needs radii and fillets and a smooth venturi into the inlet.

You could fix these problems, but this was my answer:

39mm carb into the stock airbox:

ABS plumbing fitting provide good flow with smooth radii:

The seat has a foam gasket around the edges so I don't need to run a filter cover. It draws its air from under the tank cover and at the front of the seat so it is very waterproof. It ain't sucking water until your cojones are wet, and this Blaster floats.

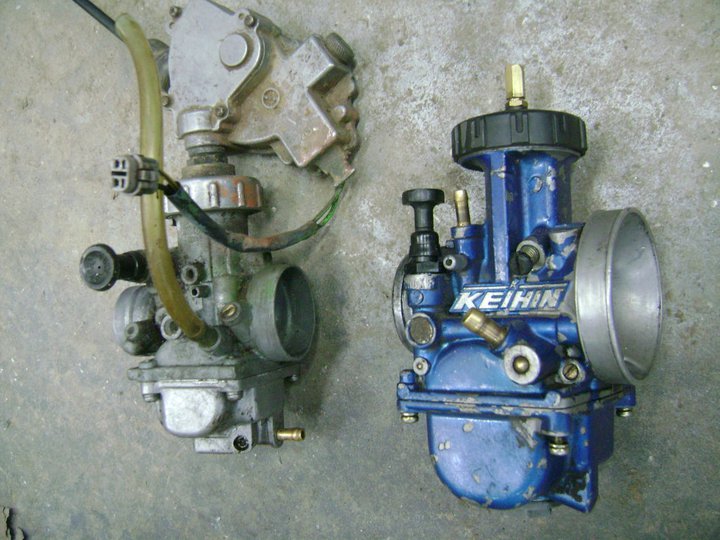

A little carb comparison:

This is on a 2003 KTM 250SX, not a Blaster motor.

Steve

Last edited:

Yeah thanks mate Iam in the middle of designing one That's similar but got all these things and a round bottom so air can flow easier. I was needing basic dimensions to work around I haven't got a blaster in middle of purchasing one just buying and making things to all go one once I get it. I will post my designs and finish product once complete. The lid that goes over the box how much of a gap does it leave at each sides when on its not flush to the side with a tight seal?

Yeah thanks mate Iam in the middle of designing one That's similar but got all these things and a round bottom so air can flow easier. I was needing basic dimensions to work around I haven't got a blaster in middle of purchasing one just buying and making things to all go one once I get it. I will post my designs and finish product once complete. The lid that goes over the box how much of a gap does it leave at each sides when on its not flush to the side with a tight seal?

Let me point out he CFM box flows plenty for a 32mm or smaller carb on a 200cc 35hp motor. It seals well, but could be better in the flow and tune department for larger motors.

I am using my gasketed seat bottom as the lid, and the only gap is at the front. The gap needs to be about the same area and needs not be any larger than the carb venturi. The carb is dealing with high velocity pulsing air. The same diameter opening will flow much more constant smooth flow air. So for a 39mm carb area is about 1200mm2. A 6mm (1/4") lid opening 200mm (8") long would more than do the trick, or about a 35mm square opening or any combination getting about 1200mm2.

Where I live is very wet and muddy. Very hard to keep that stuff out of the intake so a good seal and filter is important.

The goal with any intake ducting is generally a gentle trumpet shape up from the smallest obstruction, which should be the carb venturi. Some work I have been doing with piston ported motorized bicycles show a powerful effect from straight duct and a sharp taper at just the right distance from the intake port window. Piston port engines are more affected by intake tract tuning. For reed valved engines distance to the reed is most important and should be about 7"-8" for 8000-9000 rpm.

Don't reinvent the wheel if you don't have to. I buy a lot of stuff and try it out just to know. Some amazes me, some disappoints. I can give you measurements later, but have some photos of the stock airbox and the mods I made to mine for the larger carb.

I've also worked with port dividers both before and after the carb and into the reeds. There are some impressive part throttle gains to be had and these dividers are very effective for maintaining constant port area at the reeds.

It is a big field with lots of room for experimentation and gain. I can almost guarantee you that the first airbox design you build will not be the best. Fab something up cheap and simple to test designs before you build a beauty.

Steve

Last edited:

Thanks for your help and tips. I was meaning when the lid is on the custom cfm box does the lid seal the box or is there supposed to be a gap between the lid ends and the side of air box I get that the seat seals the box but I mean the box itself is it a sealed unit or is there space between the lid and side to allow air in

It's not a sealed unit at the top. The lid is beveled down on both sides and has a .500 - .750 gap. The lid connects to the box in the front and back and is held on with a couple of bolts.

Similar threads

- Replies

- 3

- Views

- 354

- Replies

- 11

- Views

- 655