hey guys new to the forum, not new to blasters. i have a stock blaster and recently picked up a project bike for a few bucks. Pulled the head after compression and pressure testing. the bike was bored out to 68mm .080 over. New piston on the way. i cleaned up the sleeve, it wasn't a major meltdown. I found a leak in the gasket for the reads, suspect that was cause of the meltdown. looking forward im trying to get any info from someone that has set up a bike with such a big bore.

280cc Project

- Thread starter blaster280CC

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

hey guys new to the forum, not new to blasters. i have a stock blaster and recently picked up a project bike for a few bucks. Pulled the head after compression and pressure testing. the bike was bored out to 68mm .080 over. New piston on the way. i cleaned up the sleeve, it wasn't a major meltdown. I found a leak in the gasket for the reads, suspect that was cause of the meltdown. looking forward im trying to get any info from someone that has set up a bike with such a big bore.

ahhh, boring .80 over does not make it a 280cc

see here for the truth ..............

http://www.blasterforum.com/threads/cylinder-bore-to-ccs.23137/

No extra setting up required!

Make sure that you leak test the engine prior to starting.

It would pay to post up the modifications so comments can be made on the choice of jets that should be in the carby.

The PO may have made some mods without bothering to alter the jetting, quite a common occurrence!

It would pay to check the piston to bore tolerances before you install the piston.

If you have ordered a forged piston, the chances are that the tolerances may be incorrect.

Did you measure the bore for taper and out of round?

Make sure that you leak test the engine prior to starting.

It would pay to post up the modifications so comments can be made on the choice of jets that should be in the carby.

The PO may have made some mods without bothering to alter the jetting, quite a common occurrence!

It would pay to check the piston to bore tolerances before you install the piston.

If you have ordered a forged piston, the chances are that the tolerances may be incorrect.

Did you measure the bore for taper and out of round?

Last edited:

welcome

sucks that you wrote blaster280cc as your profile name lol cuz it is not 280 cubic centimeters

sucks that you wrote blaster280cc as your profile name lol cuz it is not 280 cubic centimeters

yeah oh well...... i put it up to try to draw attention, theres not much info on the setup of larger boreswelcome

sucks that you wrote blaster280cc as your profile name lol cuz it is not 280 cubic centimeters

yeah i got the measurements, any suguestions on jetting?No extra setting up required!

Make sure that you leak test the engine prior to starting.

It would pay to post up the modifications so comments can be made on the choice of jets that should be in the carby.

The PO may have made some mods without bothering to alter the jetting, quite a common occurrence!

It would pay to check the piston to bore tolerances before you install the piston.

If you have ordered a forged piston, the chances are that the tolerances may be incorrect.

Did you measure the bore for taper and out of round?

Scratch the 260. I just read where its a stock blaster bored 80 over. If you are running as it came stock and the only change is larger bore then stock jetting should be fine. 80 over really isnt a large bore. You may just be able to adjust your needle clip and be fine or not touch a thing and it run fine.

Leave the needle and the jets well alone, 80 over will require absolutly no changes, unless you do further mods.

All a 80 overbore has done has increased the size to about 202cc's

All a 80 overbore has done has increased the size to about 202cc's

First off welcome. Its a verry good forum here, good pple and good info. It is a 207 cc and like others said, stick to stock jetting unless othwr mods were done. Also listen closely and do as some of the more experienced members say. Your cylinder is on its last legs, do what you can to get the most out of it.

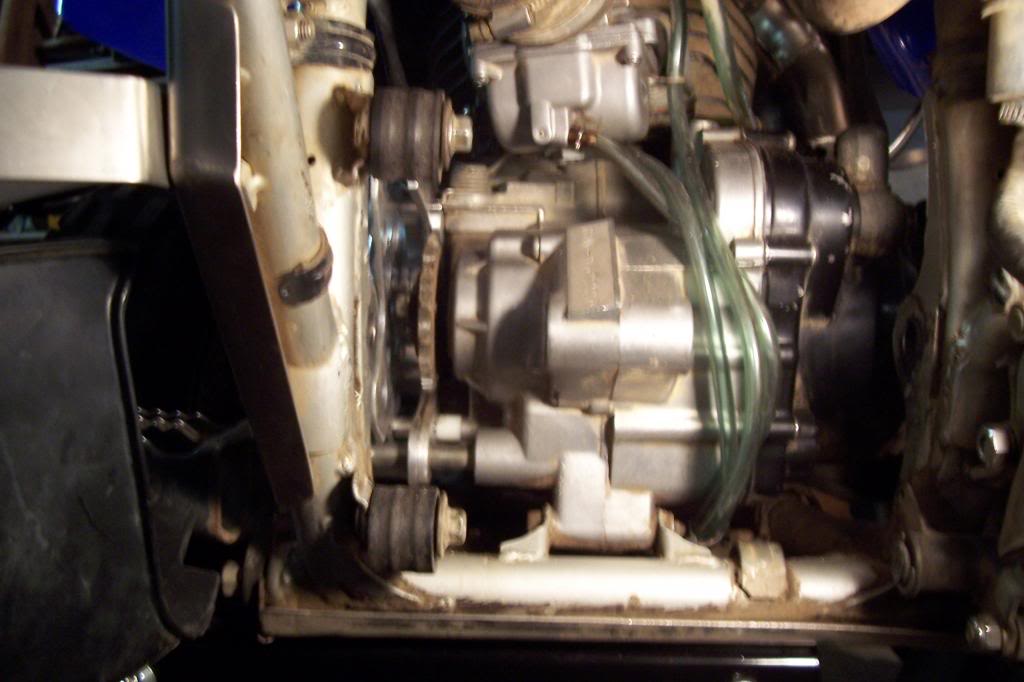

when removing the engine i noticed that the chain roller was shot so i ordered a replacement, at that time i did not notice the (metal washer/ spacer) or whatever you call it that butts to the frame has two chunks of metal missing from it. anyone know what this part is called? i would like to get it ordered asap

I found the part, it was a swing arm bushing. I think im just going to order the kit with all new bushings and bearings its pretty cheep. Thank you though

Attachments

Throw that piece of junk in the garbage and buy an aftermarket chain slide. There may also be a thin stainless sleeve on the swingarm that needs to be removed to use the aftermarket chain slide.

As far as the seal cup or whatever you call it, yeah, buy a whole swingarm pivot bearing kit. Comes with all the new parts. The chain rollers that are mounted to the frame are probably shot too. Buy aftermarket rollers with ball bearings.

Here's a great writeup on how to install them.

http://www.blasterforum.com/threads/converting-to-a-dual-bearing-chain-roller.55355/

Look up how to remove and install the bushings and bearings and pay attention when you remove the dust seals etc as some swing arms use an xtra (very thin) washer. My swing arm pivot bolt was a pita to remove, some pb blast soaking overnight did the trick.. Also have some waterproof grease ready as you are going to need it for proper install.. Like stated above, while you are already in there cut those crappy rollers off and use a bearing type like Brocno posted a great diy on. As far as another option for the swing arm roller/chain guide thingy is the T.M design chain slider. http://www.tmdesignworks.com/index.php?main_page=product_info&cPath=254&products_id=859

Similar threads

- Replies

- 3

- Views

- 274

- Replies

- 0

- Views

- 197