Civic I have read it . Not sure I fully understand it . But that I why I also feel like its too small . But I still want to put it on just to see because that's just me I have to fail to get it out of my mind that it doesn't work. Dumb maybe but it works for me lol

wwholden's head mod and arbor

- Thread starter wwholden

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

First I want to say sorry guys for not being on the forum here lately. I got a new job as a machinist and between that, school, and a girl friend, my free time has become minimal...

Your wanting the cylinders volume right. Kinda like 200cc... Isnt your formula wrong? Shouldnt it be pi x radius x stroke? And what is the stock stroke? 66 or 67?

Now based on your squish teachings Im wanting to make a head for my +3 stroker. Being that it extends the piston 1.5mm or .060 thousands plus the stock deck height would be .080 to .085 thousands total. Then the head gasket is .030 to .031 thousands. Then subtract .080 to .085 from the .030 to .031 and get .050 to .054 thousands. And I want about 40 thousands squish so I should dive my cutter in from the sealing flange approximately .010 to .014? That doesn't sound like enough. Where did I mess up? Also Im sure the proper way is to test squish and cut accordingly. But Id like a starting point on how far to take off.

Cant wait for the ass dyno report!!

The squish band is calculated by AREA, so (pi x radius x radius). You've got the diameter multiplied by 0.55 to get ~37mm

I can't remember the figures off the top of my head but it works out to be about 44mm DIAMETER for the main combustion chamber if 50% of 67mm bore is desired!

And I'm running stock bore @ 67mm too!

Your wanting the cylinders volume right. Kinda like 200cc... Isnt your formula wrong? Shouldnt it be pi x radius x stroke? And what is the stock stroke? 66 or 67?

Yeah Joe I have been wanting to make a radius tool bad for this. I have access to a knee mill also. So I should be abe to make one. It would be awesome if you could make one first and make a how to on it I:I But Im also excited about you boysen port jig.Not at all. You can go about cutting a head many different ways. Do what your comfortable with. You will systematically discover easier ways of getting the job done as you do more heads.

You will have many... "Why didn't I do it like that the first time" moments. I suggest keeping a note book with/for all your ideas.

If you really start getting into it,you might want to eventually build a

"radi cutting tool",or radius cutting tool for the lathe. Its not required to have one. I'm guilty of STILL not having built one yet. Maybe I should be building one of these instead of a "boysen port jig"?

Anyway,I have no problem duplicating heads by hand as long as I have the specs I want to cut it too.

As a side note... getting the squish distance (solder test through spark plug hole) in the 1mm to 1.25mm range is optimal. Your deck height (piston edge to top of cylinder) on a stock stroke bike will be in the .020 to .025 (thousandths) range,and the stock copper head gasket measures right at

.030 to .031 (thousandths) getting you right in the .050 to .055 thousandths range (about 1.5mm).

Also remember that you can re-use that soft copper head gasket about 2.5 million + times as long as you aneal it before each "re-use" This is cool,because its one less thing to buy. You can also make your own base gaskets using a gasket material made by felpro called "Karropak". This stuff is easy to cut and work with,and is very durable,and ...thats right...its one less thing to purchase. It comes in a few different thicknesses. I've had zero issues using it.

Here's a link to my " Do it yourself ..cutting a squish band head" video in case you haven't seen it. It may help you a bit.

http://www.blasterforum.com/engine-...high-compression-squish-band-hemi-head-50156/

Now about that porting...

Now based on your squish teachings Im wanting to make a head for my +3 stroker. Being that it extends the piston 1.5mm or .060 thousands plus the stock deck height would be .080 to .085 thousands total. Then the head gasket is .030 to .031 thousands. Then subtract .080 to .085 from the .030 to .031 and get .050 to .054 thousands. And I want about 40 thousands squish so I should dive my cutter in from the sealing flange approximately .010 to .014? That doesn't sound like enough. Where did I mess up? Also Im sure the proper way is to test squish and cut accordingly. But Id like a starting point on how far to take off.

Well I set down and cc the head and it is 17cc . Tomorrow it will go on and get tested. I think the chamber is to small and will need to be opened up bill thinks it will work. He had a mcdizzy( I think that's how you spell it) that he swears had a smaller chamber and ran great on his blasty. So only time will tell. But by this time tomorrow i hope to have a smile glued to my face lol

Cant wait for the ass dyno report!!

First I want to say sorry guys for not being on the forum here lately. I got a new job as a machinist and between that, school, and a girl friend, my free time has become minimal...

Your wanting the cylinders volume right. Kinda like 200cc... Isnt your formula wrong? Shouldnt it be pi x radius x stroke? And what is the stock stroke? 66 or 67?

Yeah Joe I have been wanting to make a radius tool bad for this. I have access to a knee mill also. So I should be abe to make one. It would be awesome if you could make one first and make a how to on it I:I But Im also excited about you boysen port jig.

Now based on your squish teachings Im wanting to make a head for my +3 stroker. Being that it extends the piston 1.5mm or .060 thousands plus the stock deck height would be .080 to .085 thousands total. Then the head gasket is .030 to .031 thousands. Then subtract .080 to .085 from the .030 to .031 and get .050 to .054 thousands. And I want about 40 thousands squish so I should dive my cutter in from the sealing flange approximately .010 to .014? That doesn't sound like enough. Where did I mess up? Also Im sure the proper way is to test squish and cut accordingly. But Id like a starting point on how far to take off.

Cant wait for the ass dyno report!!

I answered a message from 92f150300six asking about the head work,and also suggested it here in this thread,so let me elaborate a bit more deeply...

I suggested that you go to a hemi after your first test of the head which actually has a "cone shaped" combustion chamber (much like stock,but with a real/genuine squish band). I know you want to go with a "Toroidal combustion chamber shape",but I recommended the "Hemispherical" next,because you could test it and see what it does, THEN cut the toroidal. The reason for this,is because you can easily change the "Hemi" into a"Toroidal" by just removing a little bit more material from the roof of the chamber and make the walls straiter. You can't do it the other way around. Too much material would have been removed if you were to do the toroidal first.

I'm just trying to save you some time,by being able to do this ALL this machine work,testing and time with the one head your using,and end up with the finished product you want ...a "Toroidal shaped combustion chamber".

I'm guessing you only have one head to experiment on,and I'm trying to help you "kill three birds with one stone" sort of thing to save you money and time.

I guarantee that you won't want that "Cone shaped chamber". You will be cheating yourself out of power,BUT...test it first. That way you can compare all three designs. After you get to the final product your shooting for

(the toroidal),I know your going to want a "Hemi" to swap to for comparisons,so you only have to cut one more head. Two heads total.

Are you picking up what I'm putting down?

Are you smelling what I'm cooking?

Well I set down and cc the head and it is 17cc . Tomorrow it will go on and get tested. I think the chamber is to small and will need to be opened up bill thinks it will work. He had a mcdizzy( I think that's how you spell it) that he swears had a smaller chamber and ran great on his blasty. So only time will tell. But by this time tomorrow i hope to have a smile glued to my face lol

I say roll with what you have and try it out. The "Hemi" head I'm running right now is 18CC's and thats with a stock stroke crank and an increase of 1MM in exhaust port height.

Run it,and pay attention to any detonation. I doubt you'll have any. Are you running a timing advance key,or any type of timing advance? If so,you won't need it with a re-chambered head. Sporty2000 is running one of my heads on a stock bike. He hasn't squeezed everything he can get out of that head yet,but works great with the stock set up.

I answered a message from 92f150300six asking about the head work,and also suggested it here in this thread,so let me elaborate a bit more deeply...

I suggested that you go to a hemi after your first test of the head which actually has a "cone shaped" combustion chamber (much like stock,but with a real/genuine squish band). I know you want to go with a "Toroidal combustion chamber shape",but I recommended the "Hemispherical" next,because you could test it and see what it does, THEN cut the toroidal. The reason for this,is because you can easily change the "Hemi" into a"Toroidal" by just removing a little bit more material from the roof of the chamber and make the walls straiter. You can't do it the other way around. Too much material would have been removed if you were to do the toroidal first.

I'm just trying to save you some time,by being able to do this ALL this machine work,testing and time with the one head your using,and end up with the finished product you want ...a "Toroidal shaped combustion chamber".

I'm guessing you only have one head to experiment on,and I'm trying to help you "kill three birds with one stone" sort of thing to save you money and time.

I guarantee that you won't want that "Cone shaped chamber". You will be cheating yourself out of power,BUT...test it first. That way you can compare all three designs. After you get to the final product your shooting for

(the toroidal),I know your going to want a "Hemi" to swap to for comparisons,so you only have to cut one more head. Two heads total.

Are you picking up what I'm putting down?

Are you smelling what I'm cooking?

Hey joe we get what your saying and bill has a few heads to cut. I think bill posted his message before he read the pm from you and that is a good idea to go hemi next toroidale after. Ill talk with bill and see where he wants to go from here.

But about the head @ 5:21pm on a cold snowy Monday 12/10/12 . The very first wwholden head fired its first motor to life. In swaping this head I found things that I'm not real happy about. Like my quad being 80over when I bought it I was told it was only 40. I was also told it was fresh but my comp is 125psi with the old head. This seems low to me . Now with the new head it jumps to 150psi . Now what to say about this head .......hmmmm.......wow for a guy that has never rode a ported quad or modded one in this fasion . It really woke this quad up. It pulls the wheels on demand it seems to come in the band much earlier than it did. With a blip of the throttle she will sling you around. If you take it out to the blacktop it will whip a doughnut like it is its job. All in all it really made this thing come alive. Now I haven't got the chance to really open it up my yard is too small to open it all the way up. So I hope to take it to the farm this week and play a little . Now the bad it does seem to bog a tiny bit when you stab it maybe its the jetting idk. The lack of getting to really open this up is making me wonder if it will knock on the top end. But I guess we will see. Now the sad bill offered me this head to keep if I liked it . Now don't get me wrong I do like it but I don't know if I will keep it. See at a young age I learned I do t react real fast and I think I will hurt myself with this. But I want to give it a shot and ride on it a few days and see if I can get use to it. Oh as for the squish I'm going to retest it cause I don't think it was up aginst the wall cause I got .105 seems to big that's like 2 mm I think. But yeah any questions ill try and answer if you got any. Ps I know my grammer and spelling sucks. One would never know I had a 3.8 gpa when I got out of school.

I say roll with what you have and try it out. The "Hemi" head I'm running right now is 18CC's and thats with a stock stroke crank and an increase of 1MM in exhaust port height.

Run it,and pay attention to any detonation. I doubt you'll have any. Are you running a timing advance key,or any type of timing advance? If so,you won't need it with a re-chambered head. Sporty2000 is running one of my heads on a stock bike. He hasn't squeezed everything he can get out of that head yet,but works great with the stock set up.

Joe the bike is all stock besides the fmf.

Hey joe we get what your saying and bill has a few heads to cut. I think bill posted his message before he read the pm from you and that is a good idea to go hemi next toroidale after. Ill talk with bill and see where he wants to go from here.

But about the head @ 5:21pm on a cold snowy Monday 12/10/12 . The very first wwholden head fired its first motor to life. In swaping this head I found things that I'm not real happy about. Like my quad being 80over when I bought it I was told it was only 40. I was also told it was fresh but my comp is 125psi with the old head. This seems low to me . Now with the new head it jumps to 150psi . Now what to say about this head .......hmmmm.......wow for a guy that has never rode a ported quad or modded one in this fasion . It really woke this quad up. It pulls the wheels on demand it seems to come in the band much earlier than it did. With a blip of the throttle she will sling you around. If you take it out to the blacktop it will whip a doughnut like it is its job. All in all it really made this thing come alive. Now I haven't got the chance to really open it up my yard is too small to open it all the way up. So I hope to take it to the farm this week and play a little . Now the bad it does seem to bog a tiny bit when you stab it maybe its the jetting idk. The lack of getting to really open this up is making me wonder if it will knock on the top end. But I guess we will see. Now the sad bill offered me this head to keep if I liked it . Now don't get me wrong I do like it but I don't know if I will keep it. See at a young age I learned I do t react real fast and I think I will hurt myself with this. But I want to give it a shot and ride on it a few days and see if I can get use to it. Oh as for the squish I'm going to retest it cause I don't think it was up aginst the wall cause I got .105 seems to big that's like 2 mm I think. But yeah any questions ill try and answer if you got any. Ps I know my grammer and spelling sucks. One would never know I had a 3.8 gpa when I got out of school.

Great news on the power gains!!!! Sad to hear that you dont have as many bore's in that cylinder than you thought you did. Also 125psi is really good from my experience. Yamaha manual calls for 110psi. And Ive seen blasters pull hard on 60psi. Yeah recheck that squish and see if you get a different reading.... that sounds way to big. I cant wait to get my +3 stroker build going so I can try this head work for myself.

I answered a message from 92f150300six asking about the head work,and also suggested it here in this thread,so let me elaborate a bit more deeply...

I suggested that you go to a hemi after your first test of the head which actually has a "cone shaped" combustion chamber (much like stock,but with a real/genuine squish band). I know you want to go with a "Toroidal combustion chamber shape",but I recommended the "Hemispherical" next,because you could test it and see what it does, THEN cut the toroidal. The reason for this,is because you can easily change the "Hemi" into a"Toroidal" by just removing a little bit more material from the roof of the chamber and make the walls straiter. You can't do it the other way around. Too much material would have been removed if you were to do the toroidal first.

I'm just trying to save you some time,by being able to do this ALL this machine work,testing and time with the one head your using,and end up with the finished product you want ...a "Toroidal shaped combustion chamber".

I'm guessing you only have one head to experiment on,and I'm trying to help you "kill three birds with one stone" sort of thing to save you money and time.

I guarantee that you won't want that "Cone shaped chamber". You will be cheating yourself out of power,BUT...test it first. That way you can compare all three designs. After you get to the final product your shooting for

(the toroidal),I know your going to want a "Hemi" to swap to for comparisons,so you only have to cut one more head. Two heads total.

Are you picking up what I'm putting down?

Are you smelling what I'm cooking?

Yeah Joe I understand what your saying. I have several heads laying around so Ill make a couple different designs to see the comparison. Please do a how to on that radius tool pleeeaassse!!!! lol

Hey Joe Im about to cut a head for my +3 stroker and still need to know how to cut the squish.

Think you for got to answer this question that I posted above:

Based on your squish teachings Im wanting to make a head for my +3 stroker. Being that it extends the piston 1.5mm or .060 thousands plus the stock deck height would be .080 to .085 thousands total. Then the head gasket is .030 to .031 thousands. Then subtract .080 to .085 from the .030 to .031 and get .050 to .054 thousands. And I want about 40 thousands squish so I should dive my cutter in from the sealing flange approximately .010 to .014? That doesn't sound like enough. Where did I mess up? Also Im sure the proper way is to test squish and cut accordingly. But Id like a starting point on how far to take off.

Think you for got to answer this question that I posted above:

Based on your squish teachings Im wanting to make a head for my +3 stroker. Being that it extends the piston 1.5mm or .060 thousands plus the stock deck height would be .080 to .085 thousands total. Then the head gasket is .030 to .031 thousands. Then subtract .080 to .085 from the .030 to .031 and get .050 to .054 thousands. And I want about 40 thousands squish so I should dive my cutter in from the sealing flange approximately .010 to .014? That doesn't sound like enough. Where did I mess up? Also Im sure the proper way is to test squish and cut accordingly. But Id like a starting point on how far to take off.

Nice looking work wwholden.

You are onto something good here.

It looks to me like you might have more than 50% squish area. 50% whould be 46.6mm for 66mm bore.

This is not a bad thing, with the toroidal chamber it favours low and mid-range power,

as does the deep toroidal pocket.

This head with the squish set at 1mm and exhaust port roof raised 1mm (grind or shim) will make over 30hp

even with the stock pipe and carb (lid off the filter box or larger snorkle and proper jetting).

The recent trend in motocross is a shallower toroidal chamber that favours both ends of the power spectum.

Volume is important too, but not as critical as squish and shape.

18-28cc seems to work well, but like jetting, the closer to optimum the better but the more risk.

Maybe you know this already, but varsol or kerosene is an excellent cutting fluid for aluminum.

Gives better surface finish. I prefer HSS to carbide on aluminum too. Sharper, cleaner cut.

Very good stuff Mr Holden!

Do not take my words as gospel. Experiment!

If I am wrong, come back and tell me. I want to know.

Good work!

Steve

You are onto something good here.

It looks to me like you might have more than 50% squish area. 50% whould be 46.6mm for 66mm bore.

This is not a bad thing, with the toroidal chamber it favours low and mid-range power,

as does the deep toroidal pocket.

This head with the squish set at 1mm and exhaust port roof raised 1mm (grind or shim) will make over 30hp

even with the stock pipe and carb (lid off the filter box or larger snorkle and proper jetting).

The recent trend in motocross is a shallower toroidal chamber that favours both ends of the power spectum.

Volume is important too, but not as critical as squish and shape.

18-28cc seems to work well, but like jetting, the closer to optimum the better but the more risk.

Maybe you know this already, but varsol or kerosene is an excellent cutting fluid for aluminum.

Gives better surface finish. I prefer HSS to carbide on aluminum too. Sharper, cleaner cut.

Very good stuff Mr Holden!

Do not take my words as gospel. Experiment!

If I am wrong, come back and tell me. I want to know.

Good work!

Steve

Looks good and keep up the good work.

Thanks man!

Be glad to do one for you.

id be intrested in one eventually. ps. youve got a pm waiting for you.

Nice looking work wwholden.

You are onto something good here.

It looks to me like you might have more than 50% squish area. 50% whould be 46.6mm for 66mm bore.

This is not a bad thing, with the toroidal chamber it favours low and mid-range power,

as does the deep toroidal pocket.

This head with the squish set at 1mm and exhaust port roof raised 1mm (grind or shim) will make over 30hp

even with the stock pipe and carb (lid off the filter box or larger snorkle and proper jetting).

The recent trend in motocross is a shallower toroidal chamber that favours both ends of the power spectum.

Volume is important too, but not as critical as squish and shape.

18-28cc seems to work well, but like jetting, the closer to optimum the better but the more risk.

Maybe you know this already, but varsol or kerosene is an excellent cutting fluid for aluminum.

Gives better surface finish. I prefer HSS to carbide on aluminum too. Sharper, cleaner cut.

Very good stuff Mr Holden!

Do not take my words as gospel. Experiment!

If I am wrong, come back and tell me. I want to know.

Good work!

Steve

Thanks for the tips Steve!

I do not understand the math on how your getting the 46mm for a 66mm bore. Got a equation? Is the 46mm diameter of the combustion chamber?

I don't have a coolant pan on my lathe to try the citing fluids your talking about. And yeah I want to make some HSS tools to cut the aluminum and not be using my carbide. Hopefully with the money I'll get from doing this work will allow for me to buy more tooling.

They do run on premium pump gas right?

Yes they do sir. Also this head was sitting at 25cc's. Now its going to be slightly larger due to the larger squish from the stroker crank. Im guessing a stock stoke head that im rechambering should come in around 20 to 22cc's. Ill post pics and more specs when I do another one this weekend I hope.

Thanks man!

Thanks for the tips Steve!

I do not understand the math on how your getting the 46mm for a 66mm bore. Got a equation? Is the 46mm diameter of the combustion chamber?

I don't have a coolant pan on my lathe to try the citing fluids your talking about. And yeah I want to make some HSS tools to cut the aluminum and not be using my carbide. Hopefully with the money I'll get from doing this work will allow for me to buy more tooling.

The squish is 50% of area so...

the area of a 66mm head = PI x R x R = PI x D x D / 4 = 3.142 x 66mm x 66mm / 4 = 3420.77sqmm

50% of that area = 3420.77 x .50 = 1710.38sqmm

so the radius of that area = square root of ( Area / PI ) = square root of (1710.38 / 3.142) = 23.33mm

So the 50% area diameter would be = R x 2 = 23.33 x 2 = 46.66mm

That would be the diameter of the combustion chamber since both are the same area.

If you wanted 40% squish, you would calculate for 60%, make sense?

You don't need a coolant tray, just put a little varsol or paint thinner or kerosene in a pump oil can or a squirt bottle and spray a tiny bit on as you cut. Even if you had a coolant tray you wouldn't want to use a lot, it would contaminate the coolant.

As for running for running on premium gas, Holden can cut these heads to run on any fuel you want.

In fact they are very resistant to detonation, so you can run much higher compression pressure with no detonation.

The 23cc head Neil is running right now will run on regular and is making well over 30 hp.

Steve

The squish is 50% of area so...

the area of a 66mm head = PI x R x R = PI x D x D / 4 = 3.142 x 66mm x 66mm / 4 = 3420.77sqmm

50% of that area = 3420.77 x .50 = 1710.38sqmm

so the radius of that area = square root of ( Area / PI ) = square root of (1710.38 / 3.142) = 23.33mm

So the 50% area diameter would be = R x 2 = 23.33 x 2 = 46.66mm

That would be the diameter of the combustion chamber since both are the same area.

If you wanted 40% squish, you would calculate for 60%, make sense?

You don't need a coolant tray, just put a little varsol or paint thinner or kerosene in a pump oil can or a squirt bottle and spray a tiny bit on as you cut. Even if you had a coolant tray you wouldn't want to use a lot, it would contaminate the coolant.

As for running for running on premium gas, Holden can cut these heads to run on any fuel you want.

In fact they are very resistant to detonation, so you can run much higher compression pressure with no detonation.

The 23cc head Neil is running right now will run on regular and is making well over 30 hp.

Steve

Thanks for the break down. I understand the math now. Now if this is the diameter of the combustion chamber (Im talking the inner most hole near the spark plug) and you made cuts to the spark floor till you reached the desired diameter. Seem to me you would automatically come up with a certain amount of cc's. The 11 degree squish band and the squish itself would always be the same. So the only thing that determines the variation of cc's is the chambers diameter. Am I right? And isn't a toroidal head 55% instead of 50? If it was I would multiply the area by 45% right?

Also that math above has nothing to do with the stroke right? Like is there anything different for a stoker build?

Sorry for all the questions I just want to become a pro at this and your helping me clear the water. Thanks!

Thanks for the break down. I understand the math now. Now if this is the diameter of the combustion chamber (Im talking the inner most hole near the spark plug) and you made cuts to the spark floor till you reached the desired diameter. Seem to me you would automatically come up with a certain amount of cc's. The 11 degree squish band and the squish itself would always be the same. So the only thing that determines the variation of cc's is the chambers diameter. Am I right? And isn't a toroidal head 55% instead of 50? If it was I would multiply the area by 45% right?

Also that math above has nothing to do with the stroke right? Like is there anything different for a stoker build?

Sorry for all the questions I just want to become a pro at this and your helping me clear the water. Thanks!

Well we are talking squish area, so in reality we are talking the 11 degree surface.

So for a 55% squish head we would figure out the diameter of the area that is NOT the the 11degree surface.

So it is where your chamber starts, not the inner bowl diameter.

Oh, also you want a minimal (1mm?) radius in this area too.

A big radius between the quench (squish) and bowl is not helpful.

Too sharp an edge there could be prone to becoming a hot spot.

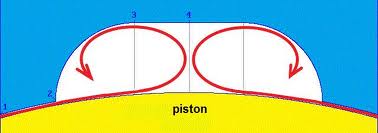

This is a lovely pict of what we are trying to achieve:

You are right, if you made cuts to the sparkplug floor till you reached the desired diameter you would pretty much have a fixed cc volume unless you vary height by cutting the gasket surface & 11 degree squish surface deeper to make the combustion chamber shallower. I did not cut my heads right down to the depth of the plug. I left a bit of the cone chamber for this reason and to allow further experimentation. This is a bit sloppy, it shades the plug a bit and leaves a small pocket of potentially unswept gasses but it made it easier to get my volumes and left more aluminum on the head. It also makes the plug less prone to splash fouling at the slight expense of power and clear plug reads. Look closely near the plug hole:

Another trick to get a small volume is to change the angle or radius of the toroidal chamber. The larger the radius = smaller volume (and better sweep of gasses), same with a shallower angle. Here is an extreme example of 45% squish shallow angle toroidal chamber (06KTM300):

This is a high rpm big bore engine, the shallow chamber and 45% squish contribute to the rpm capability,

the toroidal chamber shape contributes to mid-range torque.

This is really a compromise between a hemi and a toroidal, isn't it?

I bring it up to show that you can even cut them without a radius cutter for the bowl,

although in my opinion shape you are presently using is much better suited to a torquey 8000-9000rpm Blaster.

I think I would stick with close to 50% squish or less for high rpm or big bore machines.

That said, don't alter that head you cut, RUN IT! I'll bet you will like it.

You will have more power and it will be gutsy on the low end too.

You are right, the above math has nothing to do with stroke.

Just bore diameter to find 50% area.

Stroke enters into your squish figuring, and displacement to your cc volume.

Whew, all this typing took a whole coffee! Rock on brother!

Steve

Be careful with squish areas north of about 60% of the bore area. During my experiments I cut a head which, by volume was acceptable but had a 65% squish area (deep combustion chamber) to try and get more "torque" from the motor. The head would detonate in mid rpm (as predicted by the head design program!) even before it was warm good. It was pushing the charge too far which was putting too much energy into the mixture and getting it to ignite.

Just be very mindful that too much squish area isn't always better.

Just be very mindful that too much squish area isn't always better.

Well we are talking squish area, so in reality we are talking the 11 degree surface.

So for a 55% squish head we would figure out the diameter of the area that is NOT the the 11degree surface.

So it is where your chamber starts, not the inner bowl diameter.

Oh, also you want a minimal (1mm?) radius in this area too.

A big radius between the quench (squish) and bowl is not helpful.

Too sharp an edge there could be prone to becoming a hot spot.

This is a lovely pict of what we are trying to achieve:

You are right, if you made cuts to the sparkplug floor till you reached the desired diameter you would pretty much have a fixed cc volume unless you vary height by cutting the gasket surface & 11 degree squish surface deeper to make the combustion chamber shallower. I did not cut my heads right down to the depth of the plug. I left a bit of the cone chamber for this reason and to allow further experimentation. This is a bit sloppy, it shades the plug a bit and leaves a small pocket of potentially unswept gasses but it made it easier to get my volumes and left more aluminum on the head. It also makes the plug less prone to splash fouling at the slight expense of power and clear plug reads. Look closely near the plug hole:

Another trick to get a small volume is to change the angle or radius of the toroidal chamber. The larger the radius = smaller volume (and better sweep of gasses), same with a shallower angle. Here is an extreme example of 45% squish shallow angle toroidal chamber (06KTM300):

This is a high rpm big bore engine, the shallow chamber and 45% squish contribute to the rpm capability,

the toroidal chamber shape contributes to mid-range torque.

This is really a compromise between a hemi and a toroidal, isn't it?

I bring it up to show that you can even cut them without a radius cutter for the bowl,

although in my opinion shape you are presently using is much better suited to a torquey 8000-9000rpm Blaster.

I think I would stick with close to 50% squish or less for high rpm or big bore machines.

That said, don't alter that head you cut, RUN IT! I'll bet you will like it.

You will have more power and it will be gutsy on the low end too.

You are right, the above math has nothing to do with stroke.

Just bore diameter to find 50% area.

Stroke enters into your squish figuring, and displacement to your cc volume.

Whew, all this typing took a whole coffee! Rock on brother!

Steve

Ok Im getting this slowly. Basically the say desired 50% squish is achieved by cutting the 11deg angle deeper into the head until you reach 45% of your bore size by measuring between the squish band or across the combustion chamber.

You say something about a 1mm radius. Is this the radius down on the spark plug floor to combustion chambers walls? Or is this radius from the top of the combustion chamber walls to the squish band?

You also say to achieve the desired cc volume that I can make the walls of the combustion chamber angled? Joe told me that a toroidal head has parallel walls perpendicular to the spark plug floor. But your saying its okay to cut them angled? Did you see my first head I cut on this thread.... it was done that way?

This last head I cut came in around 24-26cc's. What effect will this have vs a head that was say 18cc's? Is the smalled cc's aimed at getting higher compression? Again this head was for my +3 stroker build so thats why I have a larger amount of cc's but I thin I could cut another one using the methods you described above to change the area.

Be careful with squish areas north of about 60% of the bore area. During my experiments I cut a head which, by volume was acceptable but had a 65% squish area (deep combustion chamber) to try and get more "torque" from the motor. The head would detonate in mid rpm (as predicted by the head design program!) even before it was warm good. It was pushing the charge too far which was putting too much energy into the mixture and getting it to ignite.

Just be very mindful that too much squish area isn't always better.

What head design program are you referring to?

Joe told me that a toroidal head has parallel walls perpendicular to the spark plug floor. But your saying its okay to cut them angled?

No...Actually you asked me how I machined the head I did. I machined it to the specs that "best" (steve) requested.

Remember that there are many styles of "toroidal" combustion chambers. Steve has many illustrations of the "toroidal" shapes in his threads including this one.

I think your doing a GREAT job! A torroidal can be an actual,true,

"sliced through the middle donut shape",it can be like the one I machined,or it could have angled sides,or?

You can cut many "toroidal" combustion chambers,and still have many different,but basic "toroidal" shapes. Have you tested any of these toroidal heads yet? I bet they work good.

To get a smaller CC chamber, your going to have to take alot more material off the head before you start cutting the squish band and chamber. I can still see the original gasket "base" cast into the head on the head that your machining. That is why you have such a deep combustion chamber.

Just for the record... There is a ton of material in the stock head,so you would be hard pressed to actually "cut through" and screw up. Trust me...

lots of material there to experiment with.