Looks like I'll be build a new pipe for my friends blaster soon. I've done plenty of math/research/made a pipe before on my yt175 with good results. The thread for that is on here at 3wheelerworld.com

So, I decided I'd share with the world, some of the information. Everything is going to be based off of my brother, N8tsNastyBlasty's Port design.

So before i post up pics, I'll mention something I noticed with all blasters. It's a stretch to reach 35hp without big bore/stroking. Most dyno's i see are 30-35hp. My program has estimated power ratings relative to displacement/rpm/compression. It's a long stretch to reach 52HP with a 200cc engine runnin 10,500rpm. The biggest factor is heat, at 52hp with 10500 on a 200cc engine, your looking at exhaust temps close to 712c. This probably doesn't mean much until you realize the blaster shouldn't push over 500c. When the exhaust temps are high, so are the piston, cylinder, rod, and everything else . To much heat and you'll seize your piston(you can get them thermally coated). I have a feeling that the cooling fins on my brothers and my friends blasters will have the cooling fins extended... So, with all that being said, I'm going to toss up a couple of ideas.

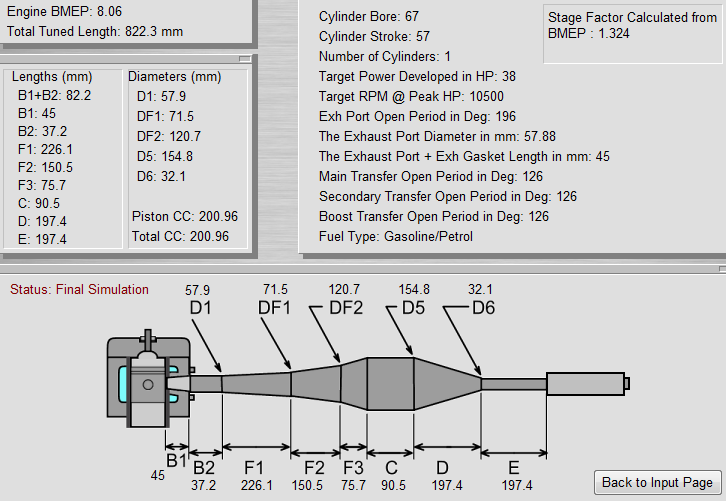

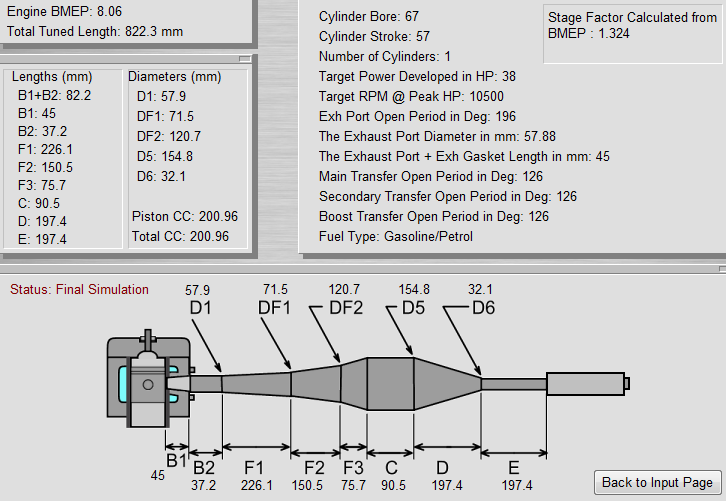

First is first, A drag racing pipe set up that is good for drag racing and then COOLING DOWN, it will be so much heat, you can only run short runs.

!!!All designs are for ported engines!!!

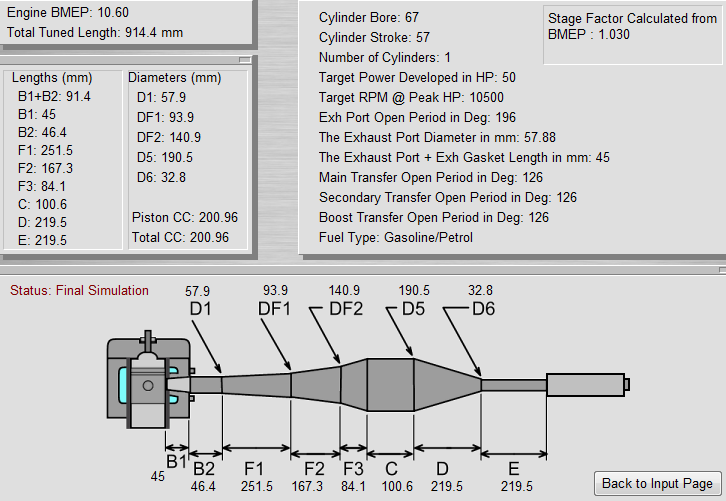

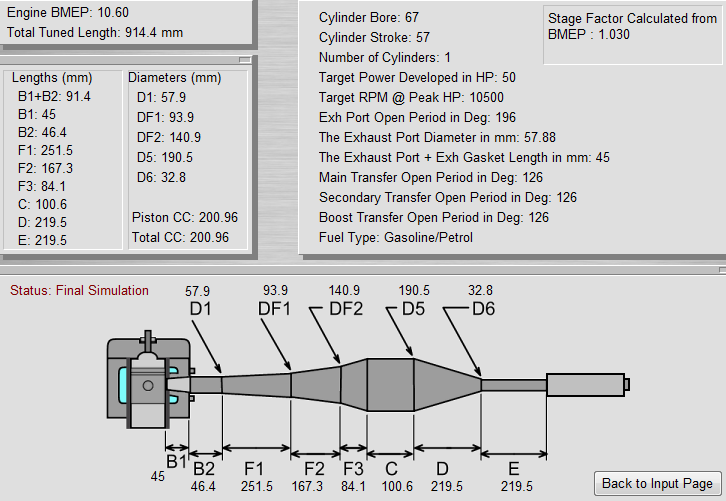

Peak power produced at 10,500RPM, 36mm Carb recommended, 50HP peak, narrow power band. 160PSI comp - I dunno about the gasoline part - pushing the limits at 160psi.

The next pipe is more of what I would consider a trail pipe. It's got a very very wide power band that peaks at 8500rpm. It's setup with no triple port exhaust, but a port timing of 185exhaust and 125 transfers. Port/pipe are set to the target RPM range. 30mm Carb recommended. Low heat, 475C. 135psi comp

This next pipe is for Nate, Set up for his port job(triple ports, ect), his peak RPM, and a nice Wide power band. Heat is on the brink of 500C. 145psi comp

So, I decided I'd share with the world, some of the information. Everything is going to be based off of my brother, N8tsNastyBlasty's Port design.

So before i post up pics, I'll mention something I noticed with all blasters. It's a stretch to reach 35hp without big bore/stroking. Most dyno's i see are 30-35hp. My program has estimated power ratings relative to displacement/rpm/compression. It's a long stretch to reach 52HP with a 200cc engine runnin 10,500rpm. The biggest factor is heat, at 52hp with 10500 on a 200cc engine, your looking at exhaust temps close to 712c. This probably doesn't mean much until you realize the blaster shouldn't push over 500c. When the exhaust temps are high, so are the piston, cylinder, rod, and everything else . To much heat and you'll seize your piston(you can get them thermally coated). I have a feeling that the cooling fins on my brothers and my friends blasters will have the cooling fins extended... So, with all that being said, I'm going to toss up a couple of ideas.

First is first, A drag racing pipe set up that is good for drag racing and then COOLING DOWN, it will be so much heat, you can only run short runs.

!!!All designs are for ported engines!!!

Peak power produced at 10,500RPM, 36mm Carb recommended, 50HP peak, narrow power band. 160PSI comp - I dunno about the gasoline part - pushing the limits at 160psi.

The next pipe is more of what I would consider a trail pipe. It's got a very very wide power band that peaks at 8500rpm. It's setup with no triple port exhaust, but a port timing of 185exhaust and 125 transfers. Port/pipe are set to the target RPM range. 30mm Carb recommended. Low heat, 475C. 135psi comp

This next pipe is for Nate, Set up for his port job(triple ports, ect), his peak RPM, and a nice Wide power band. Heat is on the brink of 500C. 145psi comp