More low/mid power

- Thread starter Fast6hand

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

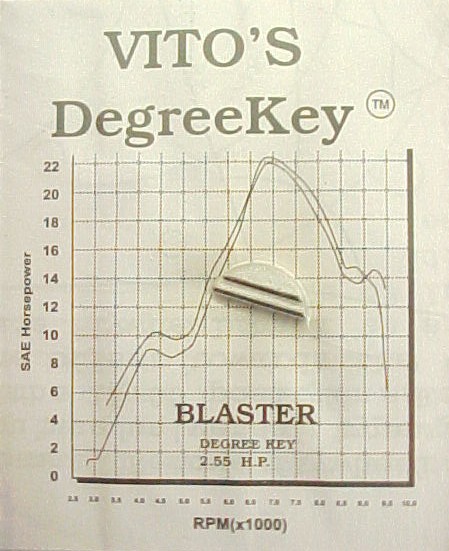

If you follow the curve that shows the extra power, it looks like it adds power from 6k to 8.5k. It looks like a loss outside of that. A lot of the charts that I found were from users claiming power everywhere, but the dyno only showed from 5k-10k (or so). If you look at a lot of them, the power is near identical at the start of the pull, but the increased timing adds power as they rev. I'd love to see a dyno of an engine done from idle to redline.

That's a very slightly clearer and larger version of the same image.

It really does look like those curves overlap at around 6k to me. Even the DR200 has timing of 8°BTDC down low and 30° higher up.

That's a very slightly clearer and larger version of the same image.

It really does look like those curves overlap at around 6k to me. Even the DR200 has timing of 8°BTDC down low and 30° higher up.

That vito's degree key is snake oil, it adds maybe if your Lucky 2 degrees, the only way to get 4 degrees of advance is to mod the stator plate appropriatly or buy aftermarket adjustable plate.

Timing advance is to make up for lack of cylinder pressure. When you really start making power you have to back the timing off to stock anyway. First off you need a head. The stock one is hopeless and detonation prone and limits power. I had a local machine shop mod my first one or there are members on here who really know the secrets of doing a good head. Here are a couple modified head picts:

Stock head on the right, modified in the back, 2004 KTM "torroidal" in the front:

Of course once installed you have to set the gap between the piston and the quench area of the head up to about 1mm. The stock head comes with about 3mm and cannot be corrected without detonation, especially with the timing advanced.

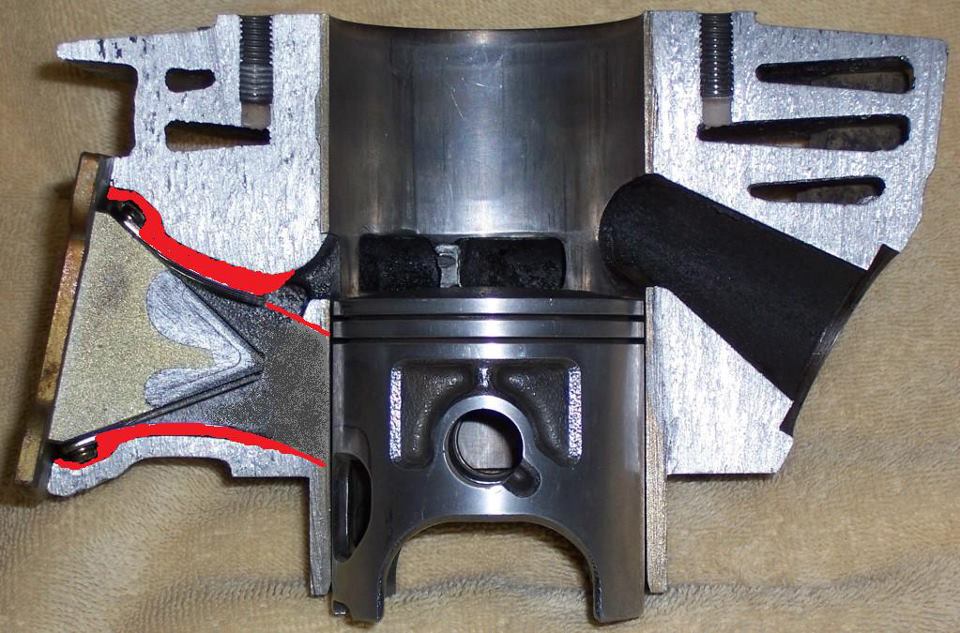

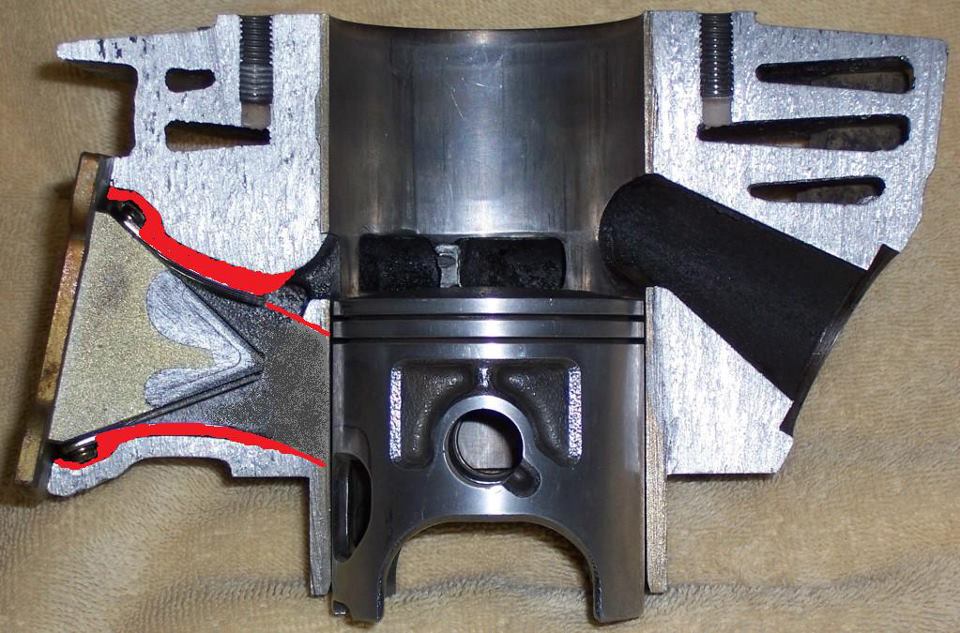

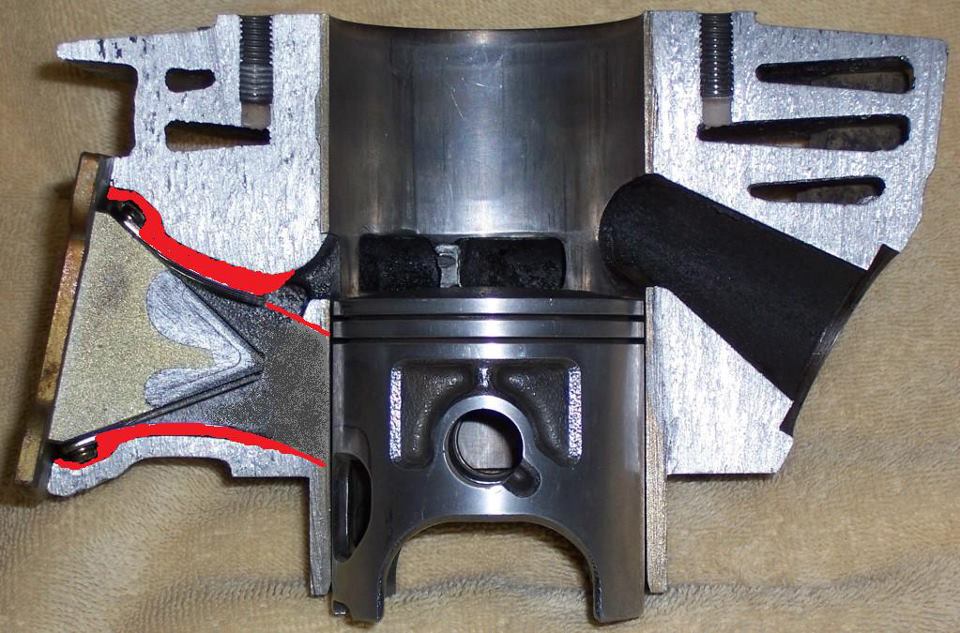

If you want low end grunt without losing top end power, the next thing you have to do is fill in the intake reed box. Ya-ya-ya we have seen beautiful pictures of ported reed boxes but picture a fuel/air mixture exiting a 26mm carb (at high speed) and dumping into a big open box. What happens? it loses momentum and the fuel drops out of suspension. So tighten up the box to the same cross sectional area as the 26mm carb, or slightly larger, trumpeting from the carb back to the port. Here is what that looks like:

Here is a cross section of the area you have to fill in in red:

And that is how you get great balls of torque on low end as well as high...

Steve

Stock head on the right, modified in the back, 2004 KTM "torroidal" in the front:

Of course once installed you have to set the gap between the piston and the quench area of the head up to about 1mm. The stock head comes with about 3mm and cannot be corrected without detonation, especially with the timing advanced.

If you want low end grunt without losing top end power, the next thing you have to do is fill in the intake reed box. Ya-ya-ya we have seen beautiful pictures of ported reed boxes but picture a fuel/air mixture exiting a 26mm carb (at high speed) and dumping into a big open box. What happens? it loses momentum and the fuel drops out of suspension. So tighten up the box to the same cross sectional area as the 26mm carb, or slightly larger, trumpeting from the carb back to the port. Here is what that looks like:

Here is a cross section of the area you have to fill in in red:

And that is how you get great balls of torque on low end as well as high...

Steve

Last edited:

True..It could be snake oil or just playing it safe. If Vitos sent out 4 degrees and they blew up a lot then he would lose business. A lot of Tuners offer the off-set keyway as a minor hop-up for all kinds of motors .That vito's degree key is snake oil, it adds maybe if your Lucky 2 degrees, the only way to get 4 degrees of advance is to mod the stator plate appropriatly or buy aftermarket adjustable plate.

Timing advance is to make up for lack of cylinder pressure. When you really start making power you have to back the timing off to stock anyway. First off you need a head. The stock one is hopeless and detonation prone and limits power. I had a local machine shop mod my first one or there are members on here who really know the secrets of doing a good head. Here are a couple modified head picts:

Stock head on the right, modified in the back, 2004 KTM "torroidal" in the front:

Of course once installed you have to set the gap between the piston and the quench area of the head up to about 1mm. The stock head comes with about 3mm and cannot be corrected without detonation, especially with the timing advanced.

If you want low end grunt without losing top end power, the next thing you have to do is fill in the intake reed box. Ya-ya-ya we have seen beautiful pictures of ported reed boxes but picture a fuel/air mixture exiting a 26mm carb (at high speed) and dumping into a big open box. What happens? it loses momentum and the fuel drops out of suspension. So tighten up the box to the same cross sectional area as the 26mm carb, or slightly larger, trumpeting from the carb back to the port. Here is what that looks like:

Here is a cross section of the area you have to fill in in red:

And that is how you get great balls of torque on low end as well as high...

Steve

I like the bigger is not always better being applied here. Most people here I bet do not even use 5th or 6th gear in daily riding. They see a pipe or porting that makes any more hp and they have to have it . Once they get to riding they find out that the power is only up top,with a 1,000 rpm range powerband. It has long been stated that HP will tell you what the engine CAN do , Torque is what it WILL do.

Timing advance is to make up for lack of cylinder pressure due to insufficient burn time.

The AFM takes time to burn and will generally do so at the same rate, although the rate of burn increases slightly with an increase in RPM due to the charge slamming upward much faster and creating turbulence.

For all intensive purposes, let's call it a roughly static rate of burn.

Your AFM takes time to burn. If peak pressure from the burn occurred at the perfect time around 5000rpm, it would burn too fast at lower RPM and create a huge problem with pumping loss. At higher RPM, you're losing out on power because your piston has been on the down-stroke by the time you reach maximum pressure. A head design will reduce the need for excessive timing.

That's why the DT200 has 8° advance t lower RPM and 30° at higher RPM.

It would be beneficial to have a dyno for selecting timing. That way, you can see if that extra degree or so is really helping out some or if it's killing power below the peak for another 2% on peak power. If only we all had a programmable ignition...

I will say that I retard my timing on my Banshee when we go woods riding and lower RPM response seems to be more prominent.

The AFM takes time to burn and will generally do so at the same rate, although the rate of burn increases slightly with an increase in RPM due to the charge slamming upward much faster and creating turbulence.

For all intensive purposes, let's call it a roughly static rate of burn.

Your AFM takes time to burn. If peak pressure from the burn occurred at the perfect time around 5000rpm, it would burn too fast at lower RPM and create a huge problem with pumping loss. At higher RPM, you're losing out on power because your piston has been on the down-stroke by the time you reach maximum pressure. A head design will reduce the need for excessive timing.

That's why the DT200 has 8° advance t lower RPM and 30° at higher RPM.

It would be beneficial to have a dyno for selecting timing. That way, you can see if that extra degree or so is really helping out some or if it's killing power below the peak for another 2% on peak power. If only we all had a programmable ignition...

I will say that I retard my timing on my Banshee when we go woods riding and lower RPM response seems to be more prominent.

Whoa! You have a few things wrong here. You are thinking 4 strokes.

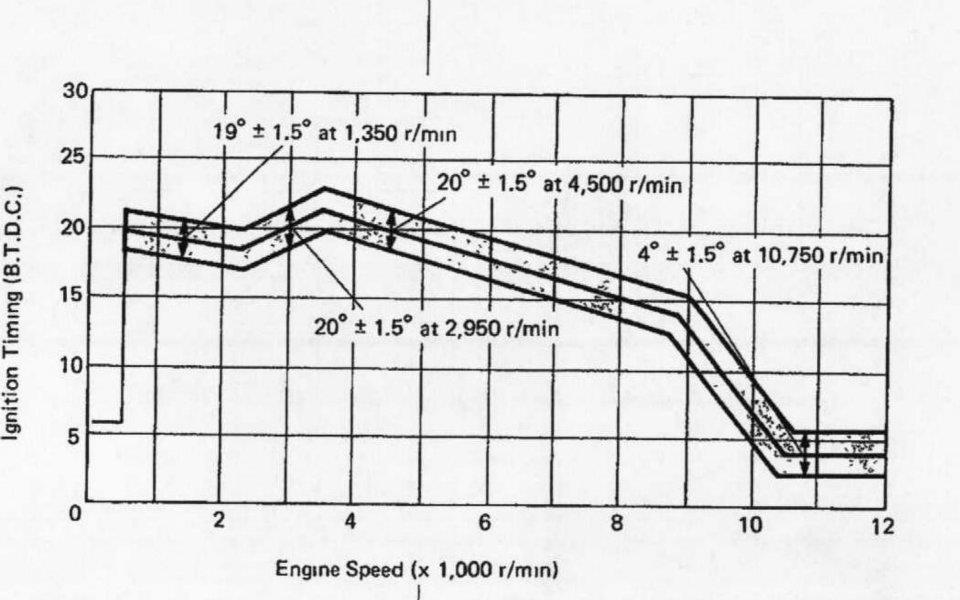

Have a close look at the DT200 timing (this is a DT125 actually):

Under 500rpm timing is 6 degrees advanced to eliminate kickback when starting.

Kind of a complicated curve under 3500rpm but essentially about 18-20 degrees peaking at 22 degrees at 3500 and RETARDING as the rpm climbs to 9000, where it backs off even faster. Why?

It is because of the pipe, building pressure like a supercharger.

You see, fuel/air does not burn at a constant rate. It is effected by droplet size, mixture ratio, temperature, pressure, compression ratio, type of fuel, and swirl velocity. In this case the pressure and swirl velocity increase with rpm and severely speed up the burn rate. We compensate by backing off the timing.

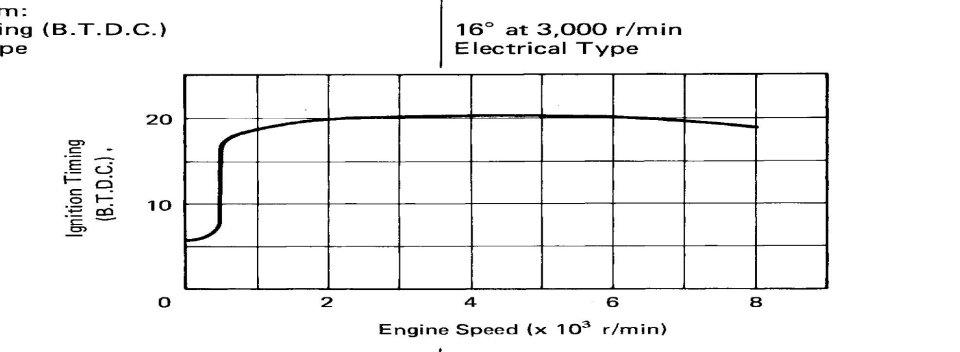

Here is the standard Blaster timing advance chart:

Not so wild as the DT125 or DT200.

Same 6 degree for starting, up to 17 degree advancing to 20 at 3500 and only backing off slightly at 7000 and 8000 rpm. The downside of this curve is if we build a wild top end pipe and porting we over pressure and risk detonation at top end rpm. Timing advance may make more power in the 1000-3000 but we risk damage at top rpm if we build the engine to make power like a DT125/200.

I hope this makes sense.

Steve Best

http://www.macdizzy.com/yfsdt_2003.htm

Chart in the middle of the page.

I assumed 30° for 4k and up. That one single part is why I thought it best to convert all of my 4-stroke head ideas over into 2-strokes. I have a bit of figuring to do.

Those that you posted do make me wonder if the timing curves were developed more for reliability than performance. I mean, the Blaster has a terrible head design and has a steady curve, so that gets my mind thinking like it was.

I guess that the somewhat proportional ratios between head flow and RPM of 4Ts kind of threw me off for a while. I mean, I know what you were saying, but I've missed it all along. Mind blown. Time for a long thinking session...

Chart in the middle of the page.

I assumed 30° for 4k and up. That one single part is why I thought it best to convert all of my 4-stroke head ideas over into 2-strokes. I have a bit of figuring to do.

Those that you posted do make me wonder if the timing curves were developed more for reliability than performance. I mean, the Blaster has a terrible head design and has a steady curve, so that gets my mind thinking like it was.

I guess that the somewhat proportional ratios between head flow and RPM of 4Ts kind of threw me off for a while. I mean, I know what you were saying, but I've missed it all along. Mind blown. Time for a long thinking session...

Last edited:

The air cooled Blaster motor was a detuned version of the water cooled motor . It was designed for torque not hp ,since any more heat RPM /HP in the head would cause it to detonate. Thats why the head first has to be re-cut when starting you start changing to higher CR , higher octane ,port timing , spark advance and higher rpm. The main clue to know what any motor design was supposed to be made for is to look at the flywheel or rotor weights.

http://www.macdizzy.com/yfsdt_2003.htm

Chart in the middle of the page.

I assumed 30° for 4k and up. That one single part is why I thought it best to convert all of my 4-stroke head ideas over into 2-strokes. I have a bit of figuring to do.

Those that you posted do make me wonder if the timing curves were developed more for reliability than performance. I mean, the Blaster has a terrible head design and has a steady curve, so that gets my mind thinking like it was.

I guess that the somewhat proportional ratios between head flow and RPM of 4Ts kind of threw me off for a while. I mean, I know what you were saying, but I've missed it all along. Mind blown. Time for a long thinking session...

I owned a DT200 for a lot of years:

It was my "second bike" for when friends came up to ride.

If I trusted you, you rode my KTM and I rode the DT200.

If I thought you'd kill yourself on the KTM you got the DT200.

Good bike, enough power to be fun (32hp), but 1st gear was short and 6th was tall.

Top speed of over 85mph on pavement and would run all day at full throttle.

McDizzy is a good and bright guy, those figures he gave:

8 BTDC @ 1350 30 BTDC @ 4000

look like measured values, the 8BTDC would have rose fast to 25BTDC at 2500

and you would have seen 20BTDC at 6000, 17BTDC at 8000 and dropping.

My son has done the DT200 swap into a Blaster.

Not too complicated but the good news is you can do as well with an air cooled jug cheaply and with a lot less complication.

Steve Best

The air cooled Blaster motor was a detuned version of the water cooled motor . It was designed for torque not hp ,since any more heat RPM /HP in the head would cause it to detonate. Thats why the head first has to be re-cut when starting you start changing to higher CR , higher octane ,port timing , spark advance and higher rpm. The main clue to know what any motor design was supposed to be made for is to look at the flywheel or rotor weights.

I don't get it?

What does that tell you?

Steve

What was the DT 200 bike motor designed for enduro or motocross ? What was the rotor/ flywheel weight compaired to the Blaster?I don't get it?

What does that tell you?

Steve

What was the DT 200 bike motor designed for enduro or motocross ? What was the rotor/ flywheel weight compaired to the Blaster?

The DT200 was designed as a cheap dualpurpose street bike. $2200 new

Wish I bought one back in 1985 instead of my XT600, heavy pig.

The flywheel is about the same weight as the Blaster, but of a different design main for the charging system. Both engines look like they came from a previous piston port (reed-less) design. I am guessing an IT200 or YZ250 motor of 1973-78 vintage? Just a guess as I don't know Yamahas of that vintage. I rode a Honda back then. The 1989 and up DT200 and WR200 used a more efficient case reed port design.

Steve

Interesting how things go around. I picked up a 1990 DT200R and I daily ride it around the city and beyond:

Not as powerful or as off-road capable as a KTM EXC, but much more acceptable on city streets.

Unlike the Blaster, the reed valve feeds directly into the crankcase, no window in the piston skirt.

The downside is that even though this motor clearly evolved from the Blaster and earlier DT200L, there is almost no parts compatibility. The engine will not swap into a Blaster, nor the cylinder onto a Blaster case.

Not as powerful or as off-road capable as a KTM EXC, but much more acceptable on city streets.

Unlike the Blaster, the reed valve feeds directly into the crankcase, no window in the piston skirt.

The downside is that even though this motor clearly evolved from the Blaster and earlier DT200L, there is almost no parts compatibility. The engine will not swap into a Blaster, nor the cylinder onto a Blaster case.

Similar threads

- Replies

- 0

- Views

- 75

- Replies

- 5

- Views

- 472