Today was the day we were going to test out the boost port and get the JoeAK47 cylinder on.

Unfortunately, we got a monster dump of snow. That slowed us down a bit.

Here is the KTM Blaster in the plowed driveway:

Well, about 4"-6" of soft wet snow, we buzzed the two Blasters around the nearest track and packed the snow down with the snowmobile.

The Blasters still scream around pretty good in the snow. Anyway, time to tear into it.

Cylinder off, piston burn pattern looks good. Yeah, the bore and piston are pretty rough, but still snug.

That is an after the fact gas smudge on the top of the piston, and yes, the engine is hard coated in mud.

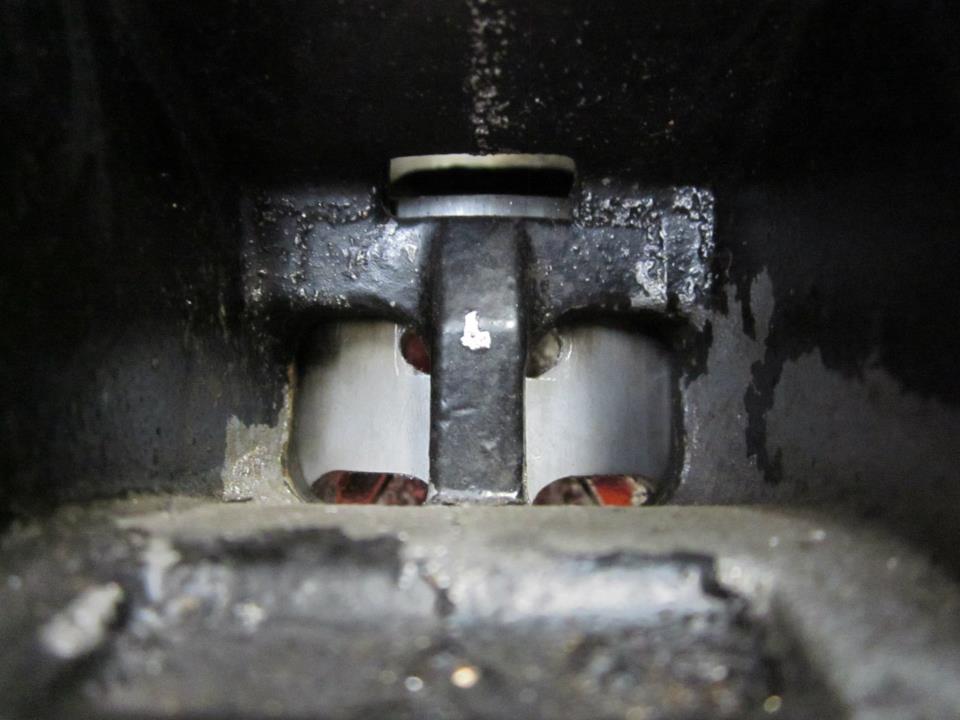

Bore to the intake side:

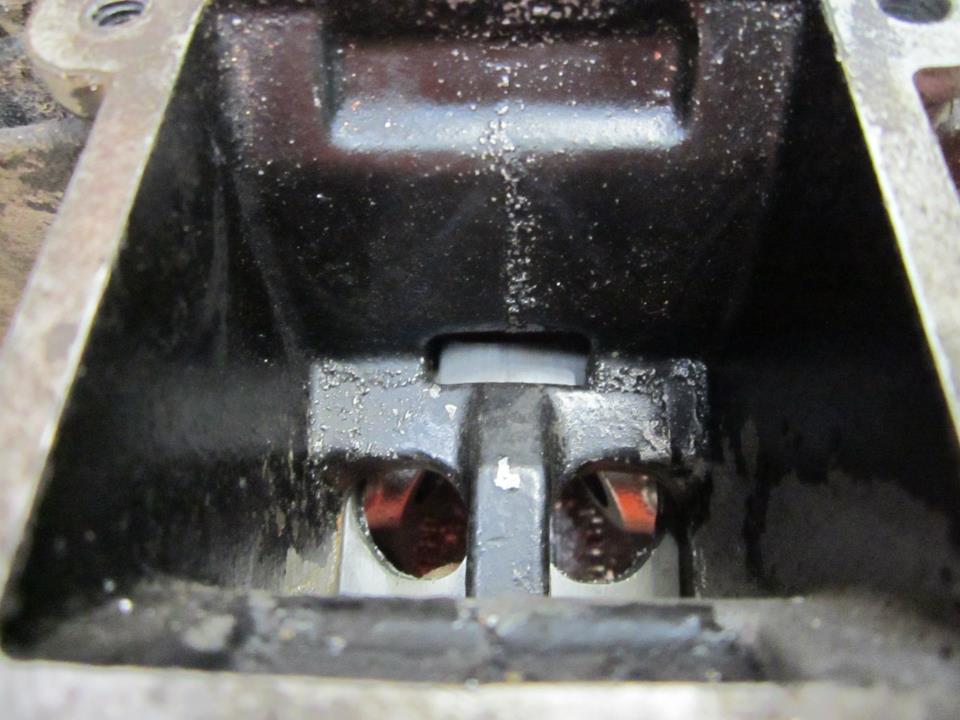

The exhaust side. Head is not wiped clean, that is how it came apart.

After some experimentation it was decided to line the piston and cylinder windows up to scribe the piston.

http://sphotos-h.ak.fbcdn.net/hphotos-ak-snc6/188643_10151385060060803_81061242_n.jpg

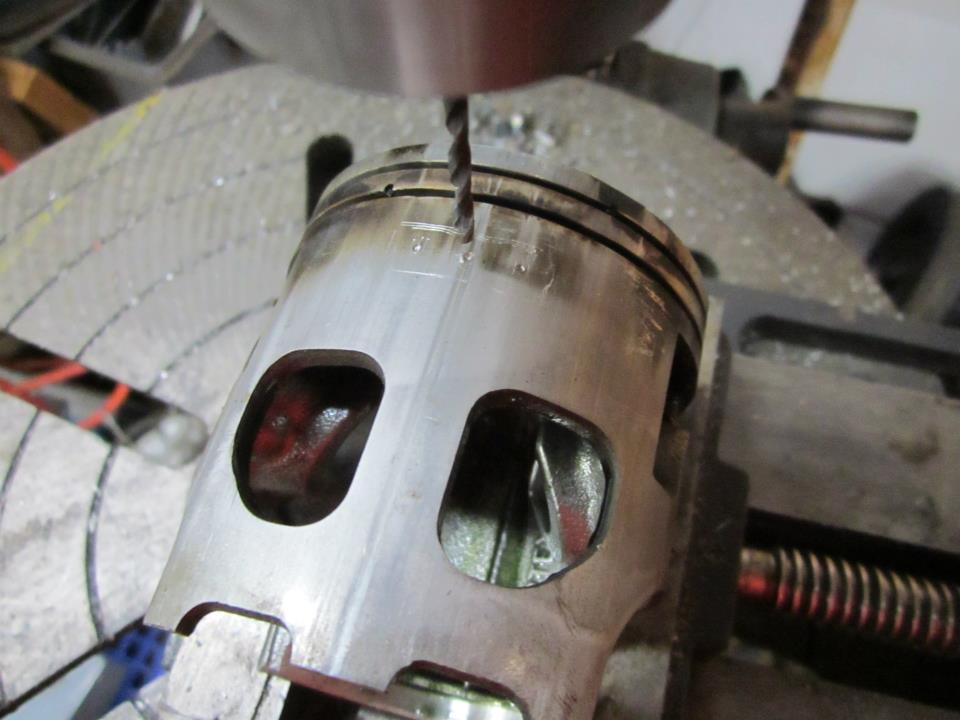

Piston prick punched and about to be pilot drilled:

Drilling in steps, connect the dots:

Note the use of soft jaws and those were the "porting tools".

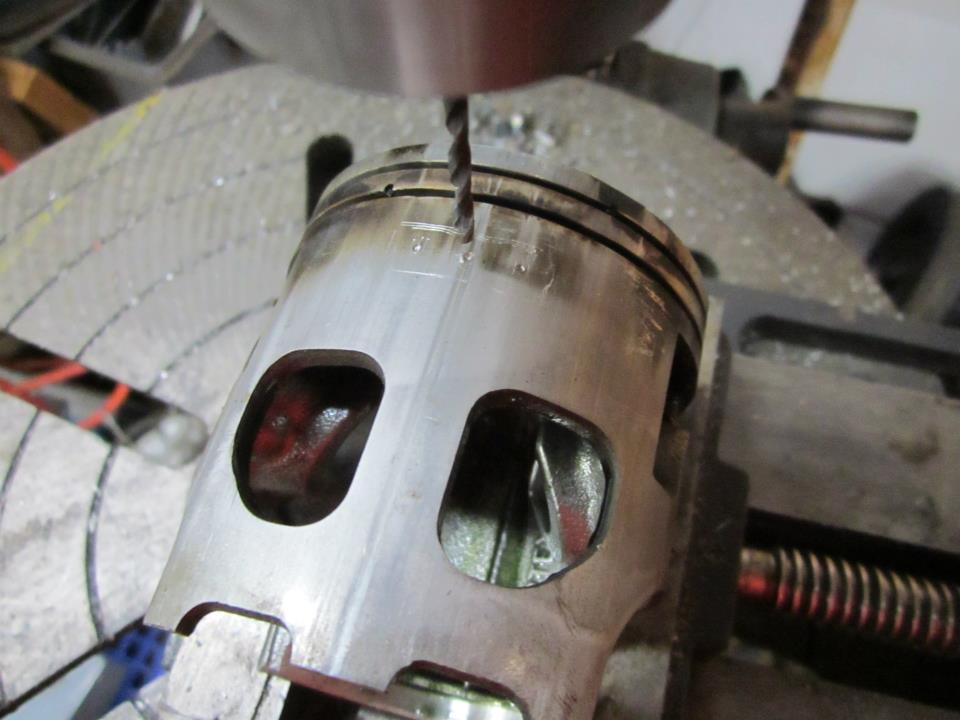

Inside view, it is the casting lines that are off, the hole is centered.

So, How does it look in the cylinder? See the next post...

Unfortunately, we got a monster dump of snow. That slowed us down a bit.

Here is the KTM Blaster in the plowed driveway:

Well, about 4"-6" of soft wet snow, we buzzed the two Blasters around the nearest track and packed the snow down with the snowmobile.

The Blasters still scream around pretty good in the snow. Anyway, time to tear into it.

Cylinder off, piston burn pattern looks good. Yeah, the bore and piston are pretty rough, but still snug.

That is an after the fact gas smudge on the top of the piston, and yes, the engine is hard coated in mud.

Bore to the intake side:

The exhaust side. Head is not wiped clean, that is how it came apart.

After some experimentation it was decided to line the piston and cylinder windows up to scribe the piston.

http://sphotos-h.ak.fbcdn.net/hphotos-ak-snc6/188643_10151385060060803_81061242_n.jpg

Piston prick punched and about to be pilot drilled:

Drilling in steps, connect the dots:

Note the use of soft jaws and those were the "porting tools".

Inside view, it is the casting lines that are off, the hole is centered.

So, How does it look in the cylinder? See the next post...