Hey guys, joined here to have a place to show my progress as I make it on this project. I'll use it as an intro as well I guess.

This project has been probably nearly 20 years in the making. I remember going to the Norm Carr Classic when I was a kid and there was always this one badass quad that had a streetbike engine in it that would destroy the other bikes there. Ever since then I've always wanted to do this. Even if it's not going to function the best, I want to do it simply for the fun of it and unique-ness.

Now that I'm much older and have some experience with cars/motorcycles, modifying, cutting, welding, cursing and all that goes on with these projects I have been keeping an eye out for deals on a cheap frame and engine. Well I've found them finally. Didn't want to spend much on this project just yet. Anyway, I picked up a blaster frame in good shape with everything that I needed from it for $225. Then I found a running yzf600 engine that had been put in a sled for $175. Now the fun begins.....

Shoving this

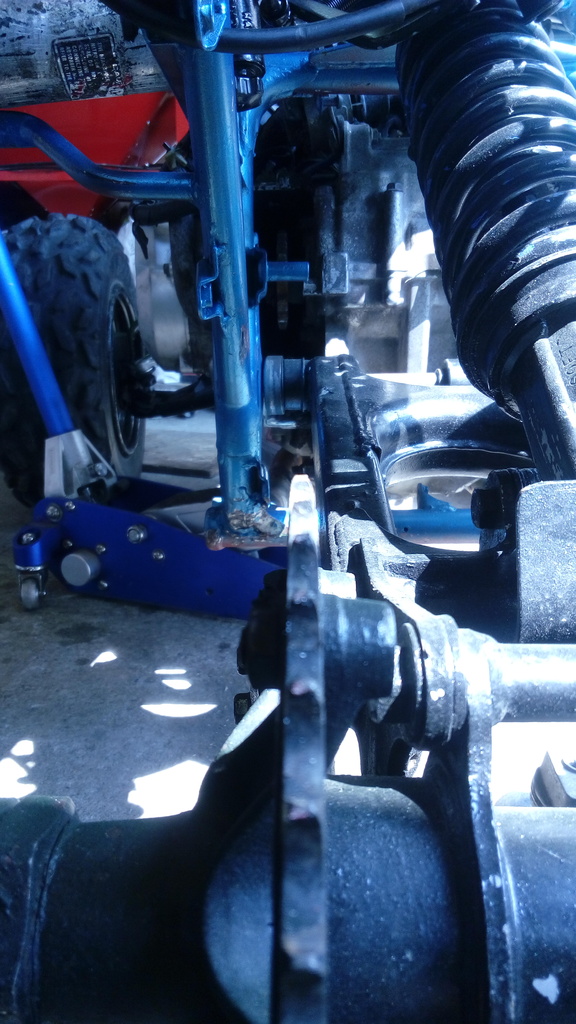

Into this

I'm just about to lift the motor out of the sled and get some measurements.

So far I know I'm going to have to cut, re-weld, gusset and strengthen the braces running from the front suspension to the lower frame tubes and extend the frame a few inches to make room for the head to clear the steering shaft. I'm hoping to lengthen the frame as little as possible as I also want to lengthen the swing arm a bit and I don't want this to be a 20' boat. I'll be strenghtening the whole frame as much as possible as well.

This project has been probably nearly 20 years in the making. I remember going to the Norm Carr Classic when I was a kid and there was always this one badass quad that had a streetbike engine in it that would destroy the other bikes there. Ever since then I've always wanted to do this. Even if it's not going to function the best, I want to do it simply for the fun of it and unique-ness.

Now that I'm much older and have some experience with cars/motorcycles, modifying, cutting, welding, cursing and all that goes on with these projects I have been keeping an eye out for deals on a cheap frame and engine. Well I've found them finally. Didn't want to spend much on this project just yet. Anyway, I picked up a blaster frame in good shape with everything that I needed from it for $225. Then I found a running yzf600 engine that had been put in a sled for $175. Now the fun begins.....

Shoving this

Into this

I'm just about to lift the motor out of the sled and get some measurements.

So far I know I'm going to have to cut, re-weld, gusset and strengthen the braces running from the front suspension to the lower frame tubes and extend the frame a few inches to make room for the head to clear the steering shaft. I'm hoping to lengthen the frame as little as possible as I also want to lengthen the swing arm a bit and I don't want this to be a 20' boat. I'll be strenghtening the whole frame as much as possible as well.