With an aftermarket filter I would use a #240 main, #32.5 pilot and the needle on the middle clip.

Adjust the float and idle and plug chop.

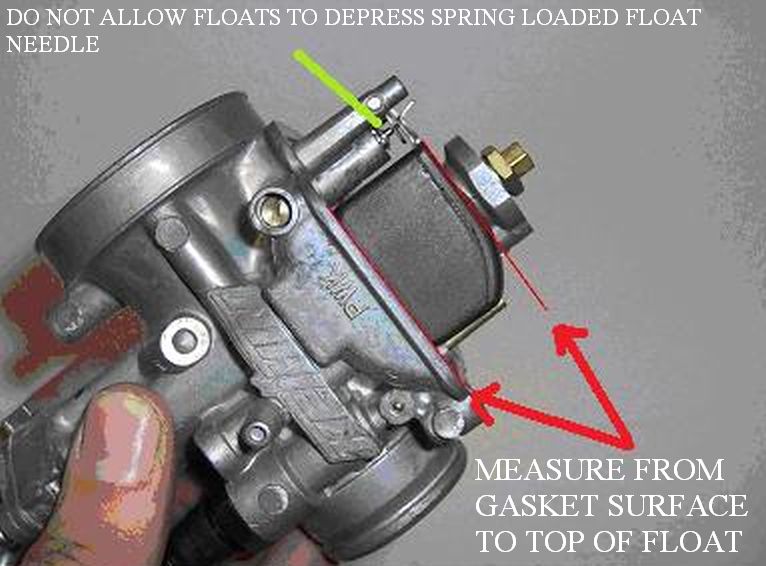

Float level should 20 to 21.5mm on a stock carby.

you want to turn the carb and hold it on a slight angle to measure the float height, like shown here......

it should just barely be touching the inner needle, not depressing it,

It is possible to check the fuel level by attaching a length of clear plastic tubing to the drain nipple , lifting it up the side of the carby, and cracking the drain screw.

The fuel should show in the pipe to the level of the carb body above the float bowl gasket.

Idle adjusting.

Set float level.

Start with air screw 1.5 turns out.

Set idle screw so that it has some sort of idle. With TORS it is the big screw under seat on top of unit. With no TORS is is the brass screw midway down carb body.

Warm up motor and then set idle screw for a faster idle, 2000rpm+

Adjust air screw either way to get the fastest idle.

Adjust air screw a little at a time leaving 10 secs or until the motor to responds.

Re adjust idle screw for desired idle .

Before you make the plug chop run it is important that the float level is correct, the idle is set correctly and there are no air leaks in the system, otherwise the smoke ring may lie about the AFR.

WHEN ALL OF THE ABOVE ARE CORRECT PROCEED WITH THE FOLLOWING.

Warm up motor to operating temp.

Fit new B8ES plug, ride through the gears and hold WOT in 5th or 6th gear for 10 seconds, or as long as you can safely.

Switch off the motor and pull in the clutch, apply brakes to come to a stop quickly.

Take the plug out and replace the old one for the ride home.

Carefully cut the threaded end off the plug to expose the insulator.

There should be a smoke ring of a cardboard or biscuit colour around the insulator.

If it is non existant or a very light colour, you are lean and require a larger main jet.

If it is a lot darker you are rich and may go down a size in main.

I prefer to run a little on the darker side, I may loose a little power but it is worth it for the peace of mind that I won't need a rebuild so soon.

http://www.blasterforum.com/do-yourself-20/how-plug-chop-38674/

http://www.blasterforum.com/engine-13/plug-chop-how-vid-48226/

This is a good to go plug.

This one is a little rich, but I would run it, I like to be on the safe side.

You have to get up a reasonable speed so that you can get the motor to pull strongly.

Then hold it Wide Open Throttle (WOT) for 10 secs or as long as you can.

The idea is not to get speed but to make it pull strong at full throttle to get onto the main jet circuit.

I find I can safely do it on a short run by applying the brakes some.

If you have not enough room you can use 4th or 5th gear with good results.