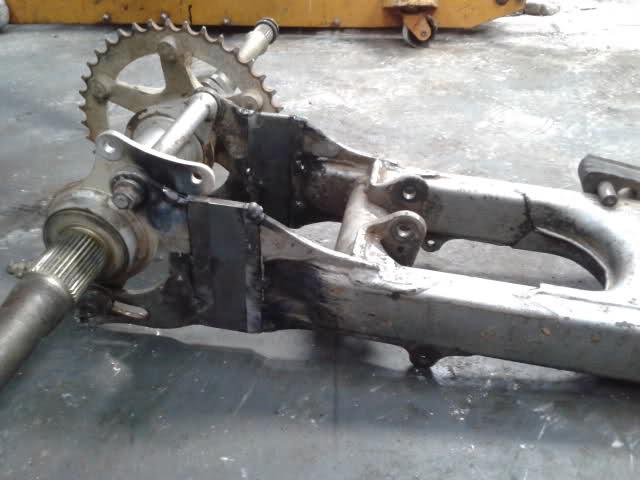

I'm planning on eventually running larger tires and of course this presents an issue with heel guard clearance. I had an extra swing arm lying around so I took an opportunity to cut it in two for the purpose of making it longer. Here are a few pics of progress this far.

Stock swing arm extension

- Thread starter dirtydeezl

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Not sure how much I'd like to extend it tho. I could just go 2" and only have to buy a longer chain. But I'm thinking 4" might be better.

You will need new sprockets also. DON'T use a new chain on used sprockets. I'm running +3 extended swing arm.

Not only for tire clearance. Once you make more than 30 hp you will find the short Blaster too prone to wheelying when you apply power or on hillclimbs. Too long an extension and it will spin too much on any low traction surface. It is a balance.

I like the idea of tack welding the angle brace before cutting. Good idea!

I cut mine further back to avoid the tube section, which I believe is chromemoly:

Chromemoly does not weld very well. It hardens and cracks at the edge of the weld.

I only went with a 2" extension on this pictured swingarm, my son and I later did 4" extensions.

If you are going to modify a stock swingarm this is the place to do it, because:

1) The weld and extension will have the least bending leverage applied to it.

2) You are welding to 1/4" mild steel, easy to get good quality welds.

3) You will have 4 runs of 4" long weld on the 1/4" plate. A lot of strength there.

4) The shock mount position is unchanged. Strength is maintained, travel increased, rate softened.

5) Added weight is kept to a minimum. 3 pieces of plate are lighter than the tube required.

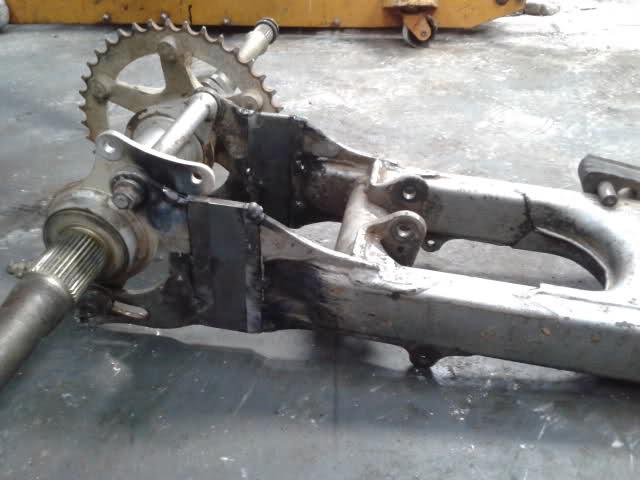

I used the bearing housing as a jig and tacked the extensions in place.

I welded in short stitches on one side then the other to keep from bending.

Makes an ugly weld but keeps it straight.

I really like your idea of tacking the two sides together and may do it on my next extension.

Finally I added a horizontal 1/8" plate to eliminate side to side flexing:

As mentioned, the short stitch welds are not a thing of beauty.

Properly braced I could do a continuous weld.

We have done several of these and so far the only problem is the X cracks that the stock arm suffers anyway.

Even the 4" is holding up well. I kinda favour a 3" extension as the best compromise. With the 4" I sometimes have trouble transferring weight back in slippery terrain. My KTM Blaster still has the 2" extension and as a trail machine I love the ability to loft the front end over logs even while speeding on wet leaves or slimy hardpacked wet mud.

The only 2wd and smallest displacement in the group. Also the lightest by 200 lbs and quickest.

I like the idea of tack welding the angle brace before cutting. Good idea!

I cut mine further back to avoid the tube section, which I believe is chromemoly:

Chromemoly does not weld very well. It hardens and cracks at the edge of the weld.

I only went with a 2" extension on this pictured swingarm, my son and I later did 4" extensions.

If you are going to modify a stock swingarm this is the place to do it, because:

1) The weld and extension will have the least bending leverage applied to it.

2) You are welding to 1/4" mild steel, easy to get good quality welds.

3) You will have 4 runs of 4" long weld on the 1/4" plate. A lot of strength there.

4) The shock mount position is unchanged. Strength is maintained, travel increased, rate softened.

5) Added weight is kept to a minimum. 3 pieces of plate are lighter than the tube required.

I used the bearing housing as a jig and tacked the extensions in place.

I welded in short stitches on one side then the other to keep from bending.

Makes an ugly weld but keeps it straight.

I really like your idea of tacking the two sides together and may do it on my next extension.

Finally I added a horizontal 1/8" plate to eliminate side to side flexing:

As mentioned, the short stitch welds are not a thing of beauty.

Properly braced I could do a continuous weld.

We have done several of these and so far the only problem is the X cracks that the stock arm suffers anyway.

Even the 4" is holding up well. I kinda favour a 3" extension as the best compromise. With the 4" I sometimes have trouble transferring weight back in slippery terrain. My KTM Blaster still has the 2" extension and as a trail machine I love the ability to loft the front end over logs even while speeding on wet leaves or slimy hardpacked wet mud.

The only 2wd and smallest displacement in the group. Also the lightest by 200 lbs and quickest.

Last edited:

Awesome input, Best! I sure wish I had done a bit more homework, but I'm notorious for learning the hard way. Lol. I really like the cross brace idea, now that I see it's not been deemed unnecessary, it assures me that my consideration of it wasn't unfounded.

I think a 3" sounds like a very reasonable amount of extension an will likely be what I go with. While I'm not overly concerned with the added weight, I've decided that I'm going to span the gap with using 3/4" square tubing top and bottom on each side, I will also use it as a cross brace sandwiched between the extension tubes. And fish a plate on the outer sides to stiffen it up.

I cut where i did for a couple reasons, according to MY logic:

1) it maintains shock mount integrity and geometry.

2) the width of the area on each side offers stable footing and increased welding surface.

Now the only thing I need to relocate are the tabs for the font f the the stock skid plate.

I think a 3" sounds like a very reasonable amount of extension an will likely be what I go with. While I'm not overly concerned with the added weight, I've decided that I'm going to span the gap with using 3/4" square tubing top and bottom on each side, I will also use it as a cross brace sandwiched between the extension tubes. And fish a plate on the outer sides to stiffen it up.

I cut where i did for a couple reasons, according to MY logic:

1) it maintains shock mount integrity and geometry.

2) the width of the area on each side offers stable footing and increased welding surface.

Now the only thing I need to relocate are the tabs for the font f the the stock skid plate.

The X is from twisting forces.

Generally if you just weld it up, it will crack again. Does not seem prone to catastrophic failure.

I welded it up and put a mild steel patch across it.

Generally if you just weld it up, it will crack again. Does not seem prone to catastrophic failure.

I welded it up and put a mild steel patch across it.

Sand the paint and dirt off before you weld it. It will weld better!!!

Oh ,.... I should sand instead of grind to bare metal? Lol. Flux core isn't as pretty as mig and truckers don't weld as good as welders and lucky for me , welders don't truck as good as truckers, lol. But I assure you, it's on there for keeps (she got all 90 amps)... It's even welded on both sides!

Thank you , bronco, you're a good egg!

Thank you , bronco, you're a good egg!

Last edited:

Lol, I thought so too , I just don't grind more than I need to expose to make the weld. Ugly welds will get ground and hit again if they have voids. By no means do I consider myself a welder, what little I think I've learned I've learned thru trial and error, but I'm happy to to say that I haven't had a bead fail on me so far (let's hope for a continued streak of good fortune!Grind is faster and easier.

You want a 4 1/2 Grinder disc on your grinder to remove metal and a 4 1/2 sanding discs on your grinder to remove paint! The Grinder disc is not going to be much or if any faster then a sanding discs. The sanding discs has less of a chance of gouging up you work.

I like to remove as much paint as i can because i hate the smell of it burning, and the smell gives me a headache. The fumes are not healthy! The burning paint smoke fogs up the welding helmet.

I like to remove as much paint as i can because i hate the smell of it burning, and the smell gives me a headache. The fumes are not healthy! The burning paint smoke fogs up the welding helmet.

We got her finished up. Painted and installed, she rides straight and doesn't throw chain so I'll claim victory on my first swing arm extension. Also put on new 13/40 sprockets, New 102 link chain and a set of used Carlisle 22" tires.

Similar threads

- Replies

- 2

- Views

- 332