Ok, here's my issue.... I got a basket case. I pieced together a blaster from a bare frame and am so close to being done. I've had to replace a lot to get this far. But most recently I put the final touches on and went to fire it up for the first time..... I got it to start once but not stay running then spent the rest of the day trying. It's got spark, a brand new plug. It's getting fuel, I even cleaned the carb again. Fresh gas. The reeds are ok. I'm at a loss. I was told crank seals, so I retraced my steps yet again and split the case to find that who ever was in there last used quick gasket instead of buying one. So I ordered a new gasket kit a few minits ago. So I'm just looking for advice.... Could it have just been that gasket? Is it the crank seals? Also I just thought about how the oil injection is not blocked off correctly. Could that be part of the reason? Is it nescasary to block it off when pre mixing? Any advice or tips would be great! Thanks for taking the timeB)

I need advice and help

- Thread starter Boombiladi

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

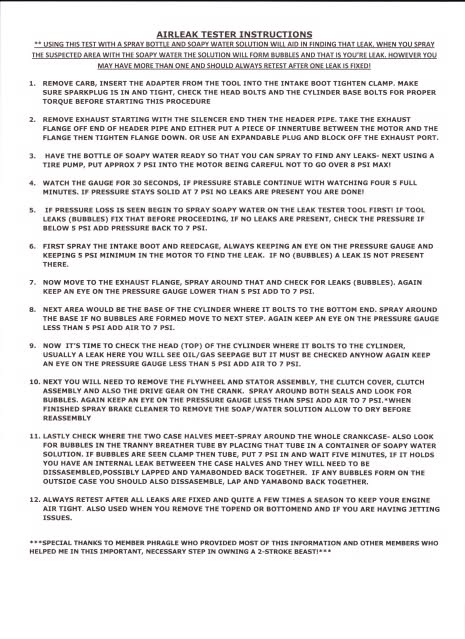

always block the injection off when premixing or you wil blow the engine from being lean. make sure the little line that brought oil into the carb from the oil injection is blocked off. also when you finished putting it all togethor you should have done a leak down to see if theres any air getting sucked into the topend causing a lean condition. can you get some pictures of this thing. also is the tors stil hooked up on it tors is the big blocky thing on top of the carb

the case halves require no gasket, just yamabond/casebond.

the flywheel cover uses a rubber gasket and the clucth cover requires one.

the crank seals are accessed from the outside under the clutch cover and flywheel cover under the stator.

yes the oil injection needs blocked off correctly, at least the inlet to the carb capped off with an 1/8" vacuum cap from any aito parts store or a piece of the line with a screw/rtv in it, that may be where you're sucking air and not starting ?

has it been leakdown tested ?

floats set ?

airscrew/pilot adjusted ?

links to those /\ can be found here, stickied at the top of the list.....

Engine - Carburetor at BlasterForum.com

or in the troubleshooting link at the bottom of my sig below \/

also....try another plug, even new ones can foul

the flywheel cover uses a rubber gasket and the clucth cover requires one.

the crank seals are accessed from the outside under the clutch cover and flywheel cover under the stator.

yes the oil injection needs blocked off correctly, at least the inlet to the carb capped off with an 1/8" vacuum cap from any aito parts store or a piece of the line with a screw/rtv in it, that may be where you're sucking air and not starting ?

has it been leakdown tested ?

floats set ?

airscrew/pilot adjusted ?

links to those /\ can be found here, stickied at the top of the list.....

Engine - Carburetor at BlasterForum.com

or in the troubleshooting link at the bottom of my sig below \/

also....try another plug, even new ones can foul

Ok, thanks for the tip... I'm not sure wich one on the carb that it was. Yes it does have the tors just isn't hooked up and there isn't anywhere to hook it up that I see. I did put a new base gasket on just not the copper one. And as for pictures, I've got a bunch that I want to put up to show my process and that may help other people out in there works but I can't figure out how.... Maybe because I'm still new, but all I have is my iPhone, I don't get Internet for my laptop so I don't know if I can from a phone... I just started a new topic actually to try to figure that out.

Last edited by a moderator:

Awesome.... I'm watching now. I was just reading about the pilot screw.... Seems very technical and I never thought it was that important. Thanks for the tips guys

On this diagram is the "control unit" make sure it IS NOT plugged in :http://www.blasterforum.com/engine-13/stock-wiring-diagrams-51842/

Also, is the spark a nice FAT BLUE or a Lazy yellow ??

FYI in the future it is easier to check for and find a leak before tearing things apart I:I

Bit of GREEN for working hard at it !!!

Also, is the spark a nice FAT BLUE or a Lazy yellow ??

FYI in the future it is easier to check for and find a leak before tearing things apart I:I

Bit of GREEN for working hard at it !!!

Awesome! Thanks for posting my pic and all the help fellas.... Glad I joined this forum. Y'all are a lot of help, and aren't dicks about it like other forums I've come across lol

Larry's shee....I'm not sure about the spark.... My buddy was looking at the spark while I kicked so I'll have to look at that myself.... And the leak down test=I never even heared of that before lol another reason I'm glad I found this place. I'm going to try and post my progress up from when I started so y'all can check it out.

Lazy spark could be from a number of things. Rust on stator poles or magnets, corrosion on terminal plugs, dirty/loose grounds, corroded switch contacs, poor ground at coil, weak coil, poor/corroded conection at plug boot, faulty plug boot. A decent multi meter will help. You can clean connections/add dielectric grease to them. Trim 1/4" off coil wire, add Di-grease- install cap, clean/grease grounds, clean switch.

Ok cool thanks for the tips.... I did find the half moon cotter key was broke that holds the flywheel on the crank so I'm getting s new one of those, and I got a new gasket and seal kit coming via wiseco so I'm going to put that all on and do a leak down test and I'll let you all know my progress! Thanks so much

If the flywheel has spun and broken the key, ther may be a good reason for it.

Have a good look at the taper in the flywheel where it goes onto the crankshaft, if it is marked in any way you may need to lap it to the shaft taper.

Have a good look at the taper in the flywheel where it goes onto the crankshaft, if it is marked in any way you may need to lap it to the shaft taper.

Similar threads

- Replies

- 5

- Views

- 223