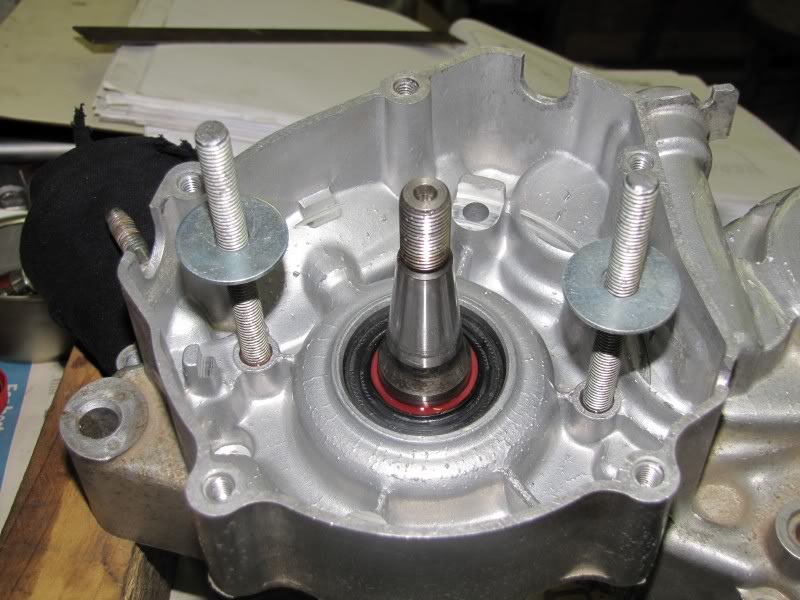

Well, i decided i needed a proper crank puller... this splitting cases without one is cave-man (african) style.

my dad whipped one up pretty fast and its proved extremely useful as I needed it to strip my spare motor, as well as my cousins motor where the casings got smashed by a snapped chain.

it is basically just a piece of channel iron! the holes are drilled the same distance apart as the threaded holes in the casings, the figures elude me at the moment. and of course a hole in the middle for the crank to fit through

Here we used 2 pieces of threaded rod with nuts underneath the channel iron to install a crank, so BOOM, it doubles as a puller and inserter

pretty simple, and very effective

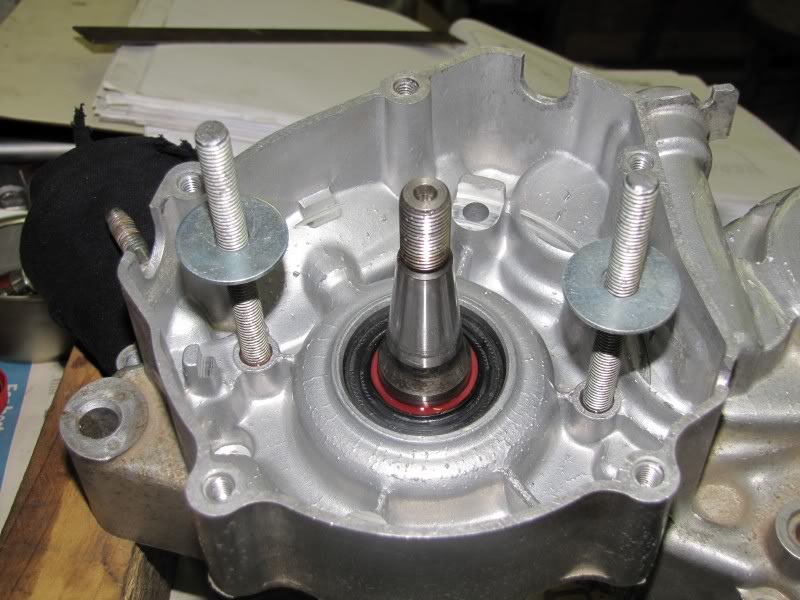

my dad whipped one up pretty fast and its proved extremely useful as I needed it to strip my spare motor, as well as my cousins motor where the casings got smashed by a snapped chain.

it is basically just a piece of channel iron! the holes are drilled the same distance apart as the threaded holes in the casings, the figures elude me at the moment. and of course a hole in the middle for the crank to fit through

Here we used 2 pieces of threaded rod with nuts underneath the channel iron to install a crank, so BOOM, it doubles as a puller and inserter

pretty simple, and very effective