By grinding away to make match, you will be increasing the volume and decreasing the bottom compression ratio. A better solution is to fill those areas in with epoxy. Any automotive grade "high temp" epoxy putty or even JB Weld (original, not quick set) will work fine. I like to sandblast, use the JB Weld to coat the metal and then build up with putty with more JB Weld to smooth and finish.

Here is a page about doing it to a reed box:

http://www.blasterforum.com/threads/improving-velocity.48827/

or here:

http://www.blasterforum.com/threads/more-low-mid-power.59613/page-2

This Blaster cylinder is still running, the epoxy still in place after 3-4 years of hard running.

I don't have any pictures of doing the cases, but I did this (case stuffing) to an aircooled 1974 CR250 many years ago and it would sail past even 1985 (when I sold it) liquid cooled and powervalved CR250s. The old Devcon epoxy and shot filler never came loose. I sold it to a guy with a new '85 who could not believe it was quicker than his new bike by a long shot. In the bottom end it is generally better to fill rather than grind.

I think I would leave the cylinder alone. The area into the port is much larger than the port itself, so just wrap the cylinder in masking tape, wax it and build up with epoxy to the cylinder. Fill in the gaps around the cylinder too. Taking off the masking tape will give the clearances needed for assembly.

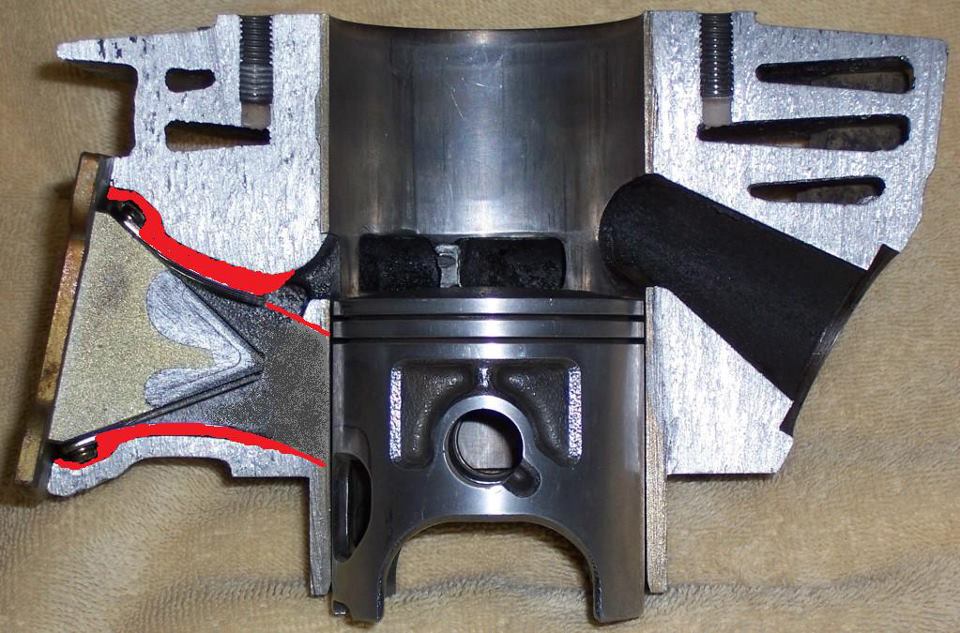

I wish I had some good case pictures for you but here in red is where I filled the reed box in with epoxy, which you can do too on your motor. It really helped the Blaster.

Notice I did away with the reed stops and made up for them with epoxy.

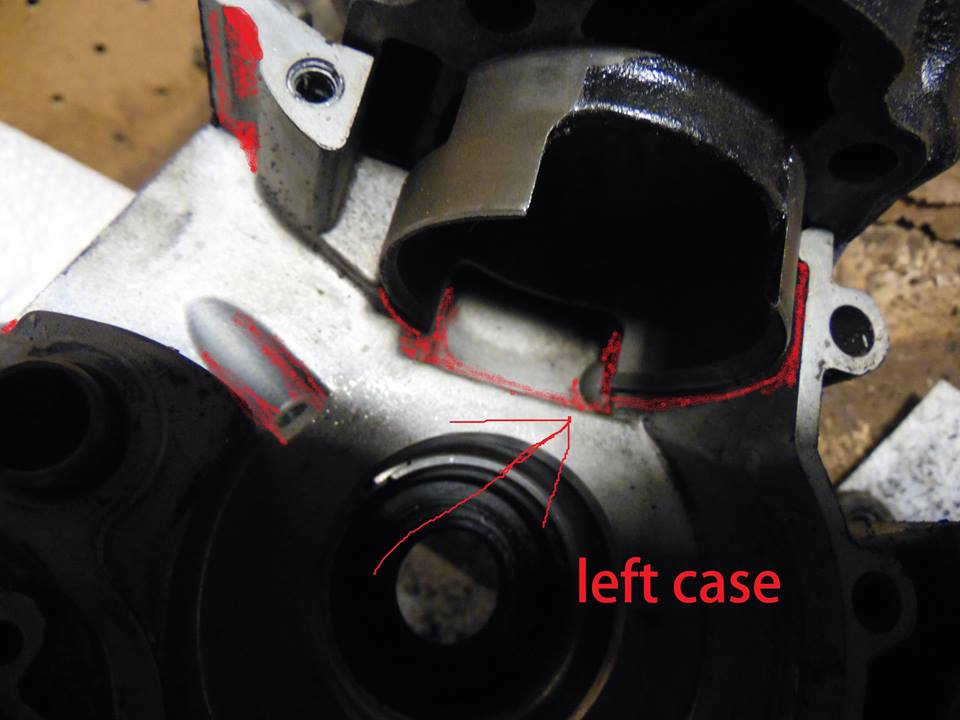

Here I have highlighted in red where you should add epoxy to the case:

Steve