I just drilled my triple exhaust ports in my blaster. How big do you guys make the holes? I drilled into the cylinder wall with a 1/4" bit and then drilled thru the exhaust port with a 3/16's drill and connected the holes. They lined up pretty good. I was just wondering how big I should try to shoot for. Thanks

Blaster triple exhaust port questions

- Thread starter Lt1350

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Actually I was asking about a 28mm carburetor, but I did apreciate very much the jetting info so now I have a much better idea where to start the jets.

I bought the quad with a broken tranny for super cheap. I tore it apart to fix it and saw the cylinder was shot which led into an entire tear down and freshen up. I have the bottom end all back together. Just have a few things left I wanted to do before I put the top end back on, and triple ports was on the list.

The triple ports are already in and line up pretty nice. I was just looking for a little info about them.

I bought the quad with a broken tranny for super cheap. I tore it apart to fix it and saw the cylinder was shot which led into an entire tear down and freshen up. I have the bottom end all back together. Just have a few things left I wanted to do before I put the top end back on, and triple ports was on the list.

The triple ports are already in and line up pretty nice. I was just looking for a little info about them.

Could you post up some pics? The location is everything.. No sense going any further if there in the wrong spot. Also you will need a right angle porting tool to do these correctly..

Both sides are pretty close to being the same height and angle in both the bore and the port. The inside of the connecting holes are just touching the sleeve on both sides, so that's as far inward as I can go. I just needed an idea how big you guys are making your ports and port holes without breaking thru the casting. Im ready to start opening the holes up but I don't want to over do it.

Not bad!

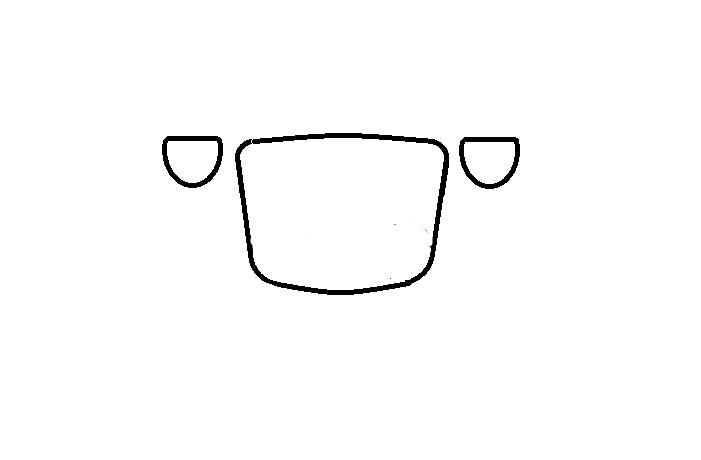

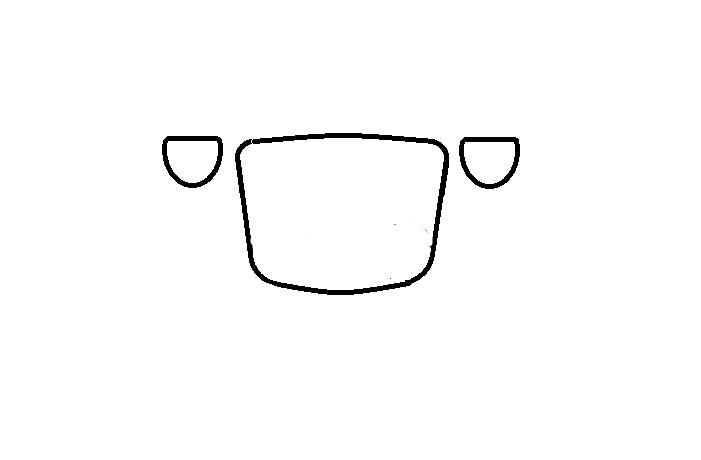

I do believe you are looking for an exhaust port and triple shape like this:

It can be done with a Dremel and some files.

The point is to get a strong exhaust signal up the pipe as the piston uncovers the ports.

Steve

I do believe you are looking for an exhaust port and triple shape like this:

It can be done with a Dremel and some files.

The point is to get a strong exhaust signal up the pipe as the piston uncovers the ports.

Steve

That picture looks like the new windows in the cylinder are at the bottom of the exhaust port? Nobody knows aproximatley how big u can make the connecting holes?

Did you just have that bored and honed? Should have done your porting first. remember to chamfer your ports and probably need another hone

Yes, I bored and honed it myself. Decided to add the ports after it was already done. I'll just tape off the bore except where I'm working and be really careful. I can dust hone it when I'm all finished

Bored it at work in a mazak vertical 655v and honed it in a sunnen cv-616. We have truing sleeves so I can rehone it and only take a few tenths out and it will still be round and straight. Shouldn't be too big of a deal, but next time I'll definitely bore it last.

The companies that offer sub exhaust ports in their cylinders ( Vitos, LA Sleeve, Airsal) build their castings around the size of the ports. They add extra material around the outside of the cylinder to get the exhaust area they need without busting out of the casting. I've seen a few builders do this mod and I for one will give you mad props for doing this. I'm sure it's not easy. What we've found at KOR is that we can simply widen the top of the exhaust port, maintain dependability, and actually gain more exhaust area than if we made sub exhaust ports. I'm sure this method also compliments the scavenging effect. If I were you, I wouldn't make them much bigger. I would widen the top of the port and get the best of both worlds. Again, nice work.

Your location looks OK. It is hard to tell without it actually being in your own hands yanno. From measuring a Vitos 240 with aux ex ports I wouldn't go any more than 5 at max 6mm on the aux ex port tunnels ( from what I'm measuring I'm getting just under 6mm ). I also you credit for this one as it not an easy task.

Edit. Comparing a Vitos 240 and an OEM cylinder side by side, the Vitos definitely has xtra material added to where the aux ex port tunnels are. I wouldn't even go close to the 6mm they have. Honestly I don't think you could make them big enough to be even worth it.

You never know until you try though, so thumbs up on attempting this one.. If you need some more measurements let me know.

Edit. Comparing a Vitos 240 and an OEM cylinder side by side, the Vitos definitely has xtra material added to where the aux ex port tunnels are. I wouldn't even go close to the 6mm they have. Honestly I don't think you could make them big enough to be even worth it.

You never know until you try though, so thumbs up on attempting this one.. If you need some more measurements let me know.

Better yet, I got a junk cylinder. I will drill through and see actually how thick it is.

3/16 bit drilled through ex port into the cyl bore (as if making aux ex port). Drilled another hole from the outer part of the cylinder (where the fins are) directly at the hole where the aux ex port now is. Let's just say in a split second It was through. Maybe 1.5 mm thick if your lucky? I'll try and take pics. It is extremely thin there after you drill the aux ex port hole.

3/16 bit drilled through ex port into the cyl bore (as if making aux ex port). Drilled another hole from the outer part of the cylinder (where the fins are) directly at the hole where the aux ex port now is. Let's just say in a split second It was through. Maybe 1.5 mm thick if your lucky? I'll try and take pics. It is extremely thin there after you drill the aux ex port hole.

Last edited:

Great, thanks for the info guys! I had a feeling I was pushing my luck trying to go much bigger thru there, but that's why I put this post up. I'll prolly just oblong the ports a little vertically and Dr. Up the port windows in the cylinder. I will definitely widen the exhaust port as Ken suggested. The more I'm getting into these motors the more it appears the exhaust port timing and configuration plays a HUGE roll in the end result. I had been focused more on the intake side until I've been researching more lately. Not to say the intake isn't important, but Im much more familiar with 4 strokes where it don't seem like the exhaust side is nearly as critical. Thanks a ton for the info guys!

That picture looks like the new windows in the cylinder are at the bottom of the exhaust port?

Ha! Then in that case you are looking at it upside down!

Nobody knows aproximatley how big u can make the connecting holes?

A lot of the advice (with some exceptions) you receive off the internet and forums is OPINION, not hard earned fact. A guy drills some triples, polishes them up perfect, and the engine works better. He will tell you the perfect size for triple ports is 6.2mm because his are 6.2mm and work great, but he really doesn't know. He did not try 6mm or 6.5mm so he will never know the optimum size.

This engine's cylinder comes apart wonderfully easy. Polish up the size you have now and try it. Some day when you have the time, haul the cylinder off and try 0.5mm larger. Do this again and again until it no longer has an effect, then you will know something for sure.

<SOME SNIPPED> The more I'm getting into these motors the more it appears the exhaust port timing and configuration plays a HUGE roll in the end result. I had been focused more on the intake side until I've been researching more lately. Not to say the intake isn't important, but Im much more familiar with 4 strokes where it don't seem like the exhaust side is nearly as critical. Thanks a ton for the info guys!

You are right, this is the case. Widening the top of the exhaust port window has an effect on waking up RPM much like raising the port but doesn't kill the mid-range torque. That is why the triples are flat-topped. The bottom of the exhaust port has little influence.

As for the intake, I found a 6mm slot in the piston and closing up the volume of the reedbox helped immensely. This piston looks like crap because it was about to be scrapped. When running on a budget, experiment on your old engines, put what you know into your new stuff:

And for epoxy stuffing the reed box:

Steve

Thanks ken, just me, and best for the great info on the exhaust side.

How wide can I go with the top of the port? I've been working on a few other thing but hope to get back to the cylinder tomorrow. I was a little worried to go too wide because the ring has to span a pretty large gap with no support when it passes over the port. But I totally get the concept of getting a strong pulse out through the pipe as you guys have mentioned.

I've always loved messing with motors and this bike won't see a ton of hours, but I would like it to run strong when I do ride it. So if it needs a ring every so often it's not a big deal to me. I haven't widened the top of the port very much yet because I don't want to mess up the cylinder by over doing it. I just need to know how much I can go with it.

How wide can I go with the top of the port? I've been working on a few other thing but hope to get back to the cylinder tomorrow. I was a little worried to go too wide because the ring has to span a pretty large gap with no support when it passes over the port. But I totally get the concept of getting a strong pulse out through the pipe as you guys have mentioned.

I've always loved messing with motors and this bike won't see a ton of hours, but I would like it to run strong when I do ride it. So if it needs a ring every so often it's not a big deal to me. I haven't widened the top of the port very much yet because I don't want to mess up the cylinder by over doing it. I just need to know how much I can go with it.

Similar threads

- Replies

- 7

- Views

- 96

- Replies

- 1

- Views

- 171

- Replies

- 1

- Views

- 69

- Replies

- 9

- Views

- 137